1993 Jeep Cherokee

1993 GENERAL SERVICING

Compressor Refrigerant Oil Checking

Chrysler Motors

* PLEASE READ THIS FIRST *

NOTE: For compressor application, see COMPRESSOR APPLICATIONS &

BODY DESIGNATIONS in this article. DO NOT exceed A/C system refrigerant oil capacity when servicing system. See REFRIGERANT OIL & REFRIGERANT SPECIFICATIONS in this article.

REFRIGERANT OIL & REFRIGERANT SPECIFICATIONS

NOTE: Due to late changes, always refer to underhood A/C

Specification Label in engine compartment or A/C compressor label while servicing A/C system. If A/C Specification Label and specifications in table differ, use label specifications.

REFRIGERANT OIL & REFRIGERANT CAPACITY TABLE (CARS)

(1) Oil Refrigerant

Application Ounces Ounces

Chrysler Corp.

All FWD Cars (2) 7.3 32

Concorde, Intrepid

& Vision 5.0 28

Laser & Talon 5.0 33

- Total system capacity, unless otherwise noted.

- With fixed displacement compressor. Use 8.7 ounces with

variable displacement compressor.

REFRIGERANT OIL & REFRIGERANT CAPACITY TABLE (LIGHT TRUCKS & VANS)

(1) Oil Refrigerant

Application Ounces Ounces

Chrysler Corp. (Except Jeep)

Dakota 4.6 44

FWD Vans (2)

With Rear Unit 13.4 50

Without Rear Unit 6.7 36

Pickup & Ramcharger 4.6 44

RWD Vans

With Rear Unit 9.3 65

Without Rear Unit 7.3 45

Jeep

Cherokee 4.6 38

Grand Cherokee (2) 8.0 28

Wrangler 4.6 32

- Total system capacity, unless otherwise noted.

- Models use R-134a refrigerant and PAG (ND8) Refrigerant Oil

(Part No. 82300102).

(3) - Models with auxiliary unit may require additional

refrigerant. See decal under hood for capacity.

- Series codes are determined by fifth character of VIN code.

- Models use PAG Refrigerant Oil (Part No. 12345923) and

R-134a refrigerant.

COMPRESSOR APPLICATIONS

NOTE: Due to late changes, always refer to underhood A/C

Specification Label in engine compartment or A/C compressor label while servicing A/C system. If A/C Specification Label and specifications differ, use label specifications.

COMPRESSOR APPLICATIONS TABLE (CARS)

Application

Chrysler Corp.

Concorde, Intrepid, Laser,

Talon & Vision

Except Concorde, Intrepid, Laser, Talon & Vision . .

Compressor

Nippondenso 10PA17 10-Cyl.

Nippondenso 6C-17 6-Cyl.,

Nippondenso 10PA17 10-Cyl.,

Sanden TR-105 10-Cyl.,

Sanden SD-709P 7-Cyl.

(1) - Body codes are determined by fourth character of VIN code.

COMPRESSOR APPLICATIONS TABLE (LIGHT TRUCKS & VANS)

Application Compressor

Chrysler Corp. (Except Jeep)

Dakota, Pickup & Ramcharger Sanden SD-709 7-Cyl.

FWD Vans Nippondenso 10PA17 10-Cyl.

RWD Vans Sanden TR-105 10-Cyl.

Jeep

Cherokee & Wrangler Sanden SD-709 7-Cyl.

Grand Cherokee Nippondenso 10PA17 10-Cyl.

(1) - Series codes are determined by fifth character of VIN code.

BODY DESIGNATIONS

BODY DESIGNATIONS TABLE (CHRYSLER CORP. CARS)

Body Designation (1) Model

"A" Body Acclaim, LeBaron Sedan & Spirit

"C" Body Dynasty & New Yorker

"G" Body Daytona

"J" Body LeBaron Convertible/Coupe

"LH" Body Concorde, Intrepid & Vision

"P" Body Shadow & Sundance

"S" Body Laser & Talon

"Y" Body Fifth Avenue & Imperial

(1) - Body codes are determined by fifth character of VIN code.

BODY DESIGNATIONS TABLE (CHRYSLER CORP. LIGHT TRUCKS & VANS)

Model Designation

Caravan "D" & "K" Series

Dakota "N" Series

Pickups (Full Size) "D" & "W" Series

Ramcharger "AD" & "AW" Series

Town & Country "Y" Series

Vans (Full Size) "B" Series

Voyager "H" & "P" Series

REFRIGERANT OILS

Only NEW, pure, moisture-free refrigerant oil should be used in A/C systems. This oil is highly refined with a very low moisture content. Oil container must be tightly closed when not in use, or moisture from air will be absorbed into refrigerant oil.

Refrigerant R-12 based systems use mineral oil, while R-134a systems use synthetic/Polyalkylene Glycol (PAG) oil. Using a mineral oil based lubricant with R-134a systems will result in A/C compressor failure due to lack of proper lubrication.

Use ONLY specified oil for the appropriate system and A/C compressor. Always check the underhood A/C specification label or A/C compressor label before adding refrigerant oil to A/C compressor/system. The following types of R-134a refrigerant oil are currently available.

Chrysler/Jeep/Eagle

PAG (ND8) Refrigerant Oil (82300102)

NOTE: Synthetic/PAG oil absorbs moisture very rapidly, 2.3-5.6 percent by weight as compared to a mineral oil absorption rate of .005 percent by weight.

SERVICING PRECAUTIONS

DISCHARGING SYSTEM

If compressor has stem-type service valves, it can be isolated and removed without discharging entire system. Otherwise, discharge A/C system using approved refrigerant recovery/recycling equipment before loosening any fittings.

DISCONNECTING LINES & FITTINGS

After system is discharged, carefully clean area around all fittings to be opened. Always use 2 wrenches when loosening or tightening fittings. Some refrigerant lines are connected with a coupling. Special tools may be required to disconnect lines. Cap all openings as soon as lines are removed. DO NOT remove caps until ready to connect lines and fittings.

NOTE: All R-134a based systems use 1/2-16 ACME threaded fittings. Ensure all replacement parts match the connections of the system being worked on.

CONNECTING LINES & FITTINGS

Always use NEW gasket or "O" ring when connecting lines or fittings. Coat "O" ring with refrigerant oil, and ensure it is not

twisted during installation. To prevent damage to lines and fittings, always use 2 wrenches.

PLACING SYSTEM IN OPERATION

After component service or replacement has been completed, evacuate system thoroughly with a vacuum pump. Charge system with proper amount of refrigerant. See REFRIGERANT OIL & REFRIGERANT SPECIFICATIONS in this article. Perform leak test. After system has been leak tested, check system operation.

NOTE: A/C systems normally will not need additional refrigerant oil unless oil loss has occurred due to ruptured lines, leaking compressor seals, compressor overhaul or component replacement.

CHECKING COMPRESSOR OIL

NIPPONDENSO 6C-17 6-CYLINDER

Slowly

discharge system using approved refrigerant

recovery/recycling

equipment. Disconnect refrigerant hoses at

compressor. Remove

compressor bolts and compressor.

Remove

suction port on top of compressor, and drain oil.

Add

proper amount of refrigerant oil to compressor (total

system

capacity minus amount retained

in components that have not been

replaced). See

6C-17 COMPONENT REFRIGERANT OIL CAPACITIES table. See

REFRIGERANT

OIL & REFRIGERANT SPECIFICATIONS in

this article for total

system capacity.

Install

compressor. Evacuate and recharge A/C system.

Perform leak test.

6C-17 COMPONENT REFRIGERANT OIL CAPACITIES

TABLE

Component Ounces

Condenser 1

Evaporator

Front 2

Rear (If Equipped) 2

Receiver-Drier 1

NIPPONDENSO 10PA17 10-CYLINDER

Chrysler Motors (Laser & Talon)

Add specified amount if components are replaced. See 10PA17 COMPONENT REFRIGERANT OIL CAPACITIES table.

Chrysler Motors (Except Laser & Talon)

Slowly

discharge system using approved refrigerant

recovery/recycling

equipment. Disconnect refrigerant hoses at

compressor. Remove

compressor bolts and compressor.

Remove

suction port on top of compressor, and drain oil.

Add

proper amount of refrigerant oil to compressor (total

system

capacity minus amount retained

in components that have not been

replaced). See 10PA17 COMPONENT

REFRIGERANT OIL CAPACITIES table. See

REFRIGERANT

OIL & REFRIGERANT SPECIFICATIONS in

this article for total

system capacity.

Install

compressor. Evacuate and recharge A/C system.

Perform leak test.

10PA17 COMPONENT REFRIGERANT OIL CAPACITIES TABLE

Component

Ounces

Laser & Talon

Compressor 1

Condenser 2/3

Evaporator 1

Receiver-Drier 1/3

Refrigerant Lines 1/3

Except Laser & Talon

Condenser 1

Evaporator

Front 2

Rear (If Equipped) 2

Receiver-Drier 1

SANDEN SD-709 & SD-709P 7-CYLINDER

Start

and operate engine at high idle with A/C on for 15

minutes.

Stop engine. Connect manifold gauge set to compressor

service

valves. Ensure valves on gauge

set are closed. Place both valves on

compressor in mid position.

Start engine, and operate A/C.

Slowly

turn compressor suction valve clockwise toward

closed

(front-seated) position. When suction pressure is reduced to

zero,

turn engine and compressor off, and quickly turn suction valve

stem

inward to full front-seated position. Turn discharge valve

into

front-seated position.

Loosen

oil level plug to release internal pressure in

compressor.

Compressor is now isolated from rest of system, and

service

valves can be removed from compressor.

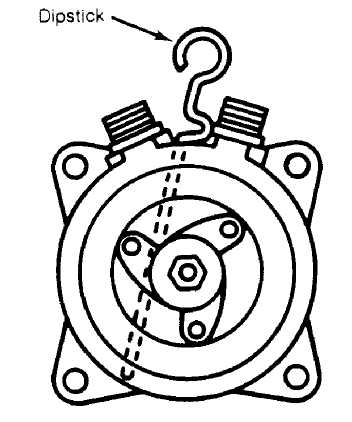

Remove

compressor oil plug. Look through oil fill plug

hole,

and rotate compressor crankshaft to allow Dipstick (6465) to

be

fully inserted. Insert Dipstick

(6465), and measure oil. See Fig. 1.

Each

mark on dipstick represents one increment.

17493

Fig. 1: Checking Compressor Oil Level Courtesy of Sanden International U.S.A., Inc.

5) Place angle gauge across flat areas on mounting ears. Determine amount of oil needed based on mounting angle. See SD-709 &

SD-709P COMPRESSOR OIL INCREMENT CAPACITIES table.

6) If necessary, correct compressor oil level. Install compressor oil plug, and tighten it to 72-108 INCH lbs. (8-12 N.m). Evacuate and recharge A/C system. Perform leak test.

SD-709 & SD-709P

COMPRESSOR OIL INCREMENT CAPACITIES TABLE

Mounting

Angle Oil Level

(Increments)

0 3-5

10 4-6

20 5-7

30 6-8

40 7-9

50 8-10

60 9-11

90 10-12

SANDEN TR-105 10-CYLINDER

Slowly

discharge system using approved refrigerant

recovery/recycling

equipment. Disconnect refrigerant hoses at

compressor. Remove

compressor bolts and compressor.

Remove

suction port on top of compressor, and drain oil.

When repairing

A/C systems with excessive leak(s), add additional oil.

Add

proper amount of refrigerant oil to compressor (total

system

capacity minus amount retained in components that have not

been

replaced). See TR-105 COMPONENT

REFRIGERANT OIL CAPACITIES table. See

REFRIGERANT

OIL & REFRIGERANT SPECIFICATIONS in

this article for total

system capacity.

Install

compressor. Evacuate and recharge A/C system.

Perform leak test.

TR-105 COMPONENT REFRIGERANT OIL CAPACITIES

TABLE

Component Ounces

Condenser 1

Evaporator

Front 2

Rear (If Equipped) 2

Receiver-Drier 1