1993 Jeep Cherokee

AUTOMATIC TRANSMISSIONS

Aisin Warner 4 Electronic Diagnosis

1993-94 Cherokee

APPLICATION

NOTE: Transmission may also be referred to as AW-4.

APPLICATION

Model Trans.

1993-94 Cherokee (1) AW-4

(1) - Used on vehicles with 4.0L 6-cylinder engine only for 1993-94 model years.

NOTE: Vehicle body code may be required when diagnosing or

repairing transmission, as body code may be used instead of vehicle model name. See BODY CODE DESIGNATION table.

BODY CODE DESIGNATION

Vehicle Model Body Code

Cherokee XJ

DESCRIPTION

The electronic control system for the AW-4 transmission controls transmission shift points and torque converter lock-up. Electronic control system consists of Transmission Control Module (TCM), valve body solenoids, throttle position sensor, speed sensor, neutral safety switch and brake switch.

NOTE: Transmission Control Module (TCM) may be referred to as

Transmission Control Unit (TCU). Neutral safety switch may be referred to as park/neutral safety switch or gear select switch.

OPERATION

TRANSMISSION CONTROL MODULE (TCM)

The TCM determines shift points and torque converter lock-up based on input signals received from throttle position sensor, neutral safety switch, speed sensor and brake switch. The TCM controls transmission shift points and torque converter lock-up by operating electric solenoids mounted on the valve body.

The TCM contains a self-diagnostic system used for

determining an electronic component failure. The TCM self-diagnostic system will store a diagnostic trouble code in the TCM memory if certain electronic problems exist. If electronic problem goes away, diagnostic trouble code will be erased from TCM memory after ignition has been cycled approximately 75 times.

NOTE:

Diagnostic trouble code may be referred to as fault code.

Diagnostic trouble codes can be retrieved using a Diagnostic Readout Box-II (DRB-II). After repairing an electrical system problem, stored diagnostic trouble code must be cleared from TCM memory.

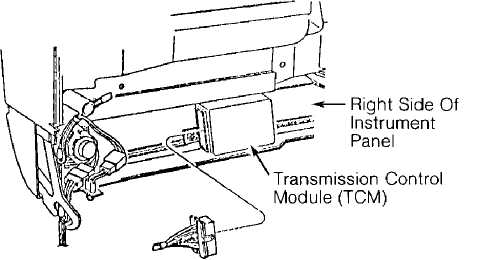

The TCM is located behind right side of instrument panel on Cherokee. See Fig. 1.

94F38401

Fig. 1: Transmission Control Module (TCM) I.D. (Cherokee) Courtesy of Chrysler Corp.

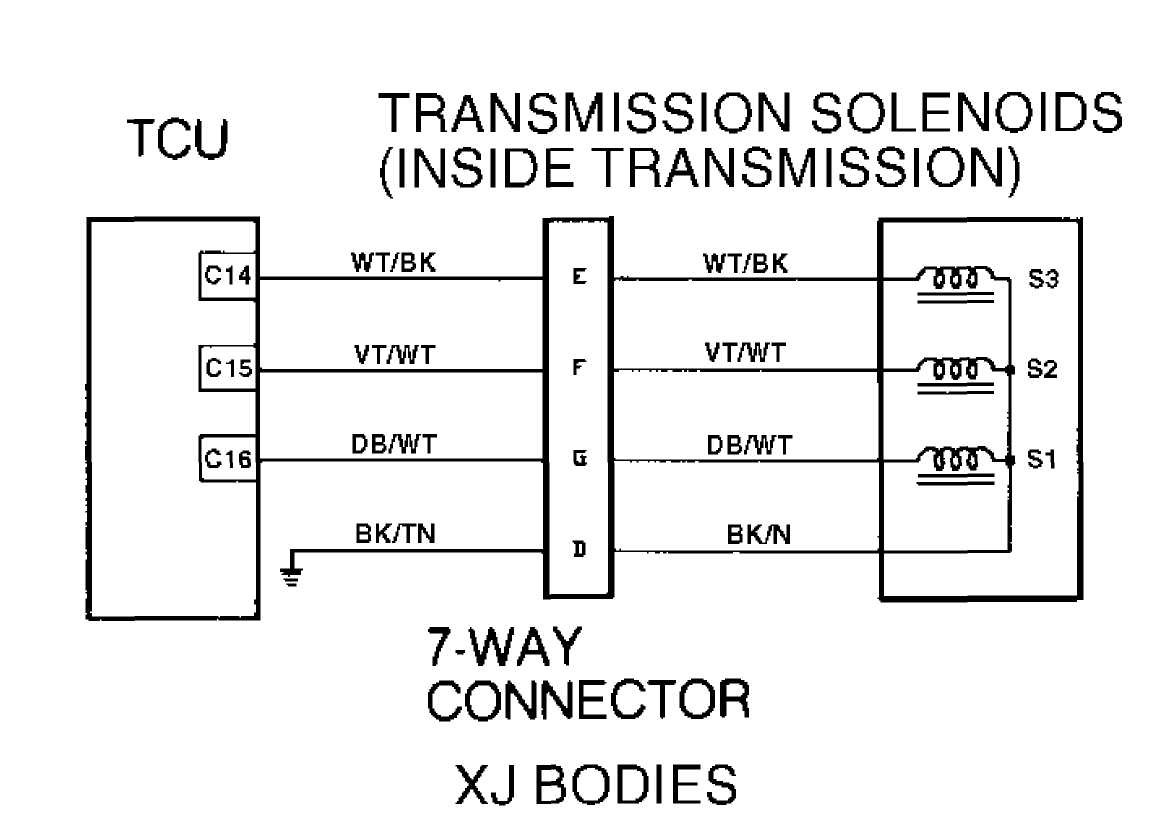

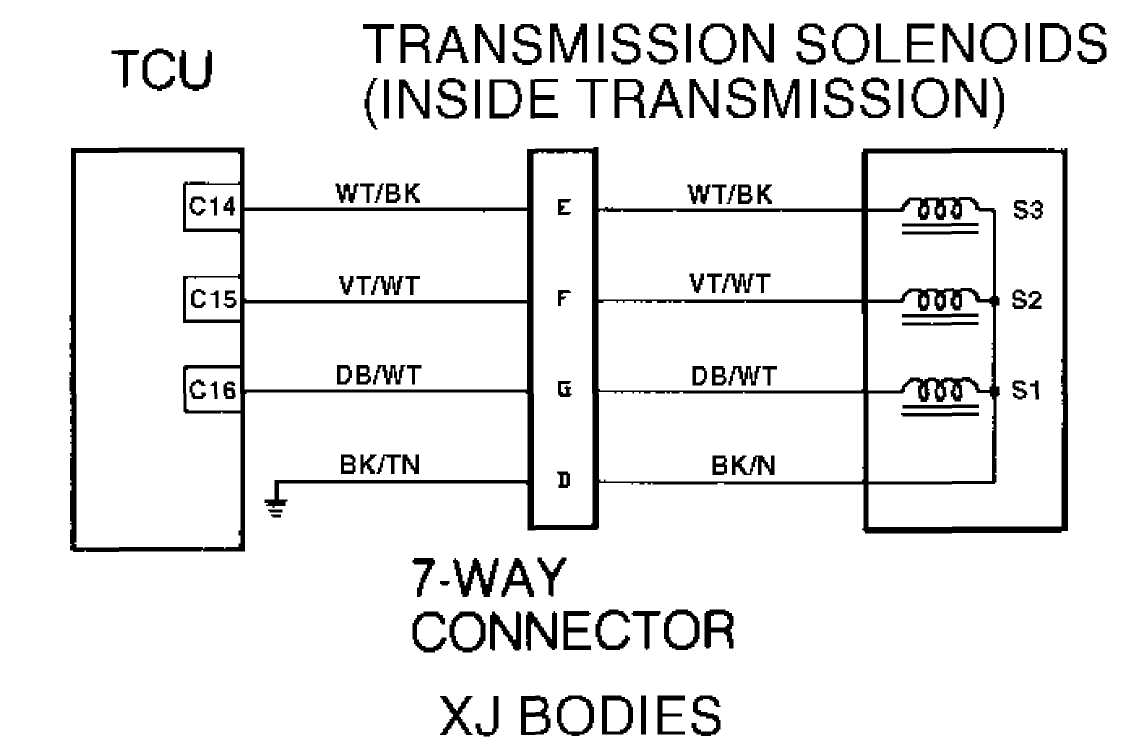

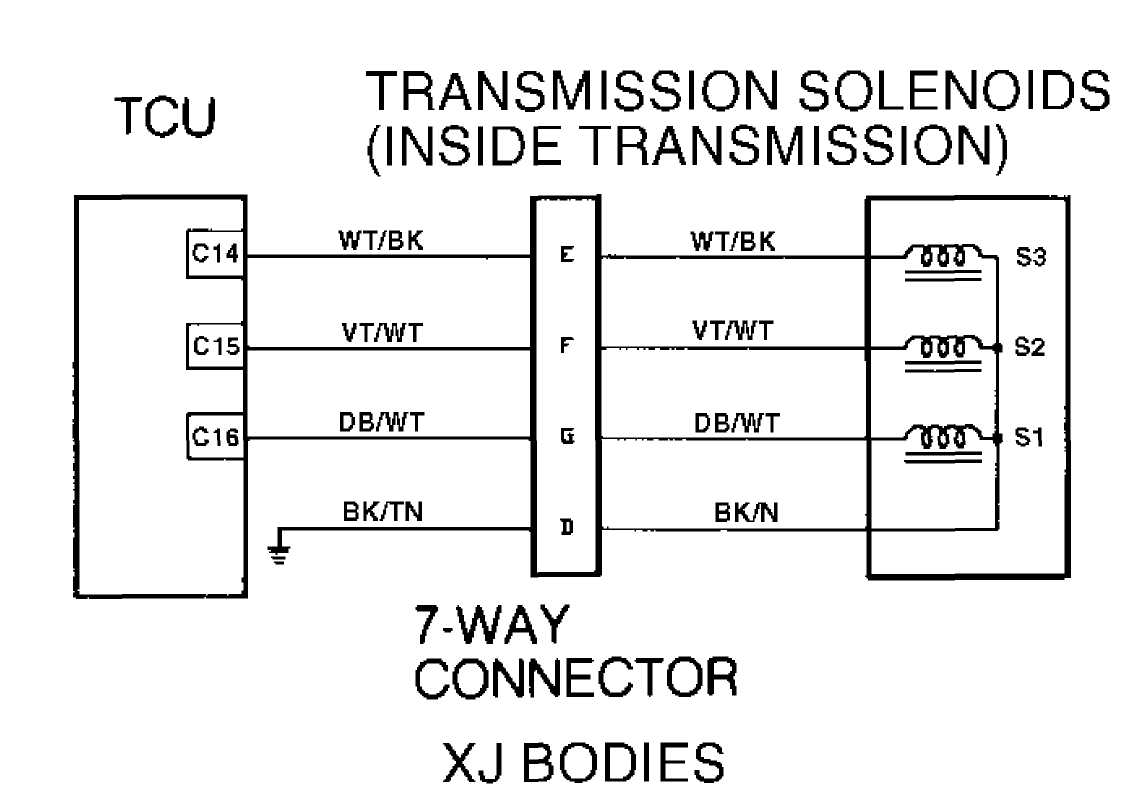

VALVE BODY SOLENOIDS

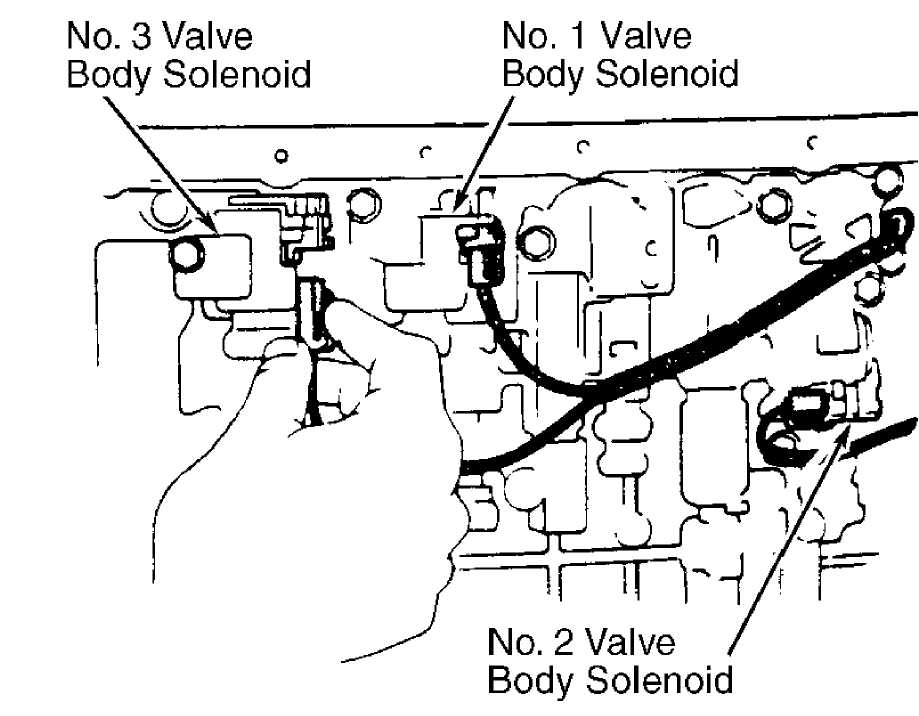

Valve body solenoids, mounted on the valve body, are output devices controlled by signals received from the TCM. See Fig. 2. The No. 1 and 2 valve body solenoids control transmission shifts while the No. 3 valve body solenoid is used for torque converter lock-up.

When No. 1 and 2 valve body solenoids are energized, solenoid plunger moves from seat. This opens the drain port and releases line pressure. When either valve body solenoid is de-energized, plunger closes the drain port.

The No. 3 valve body solenoid operates in reverse. When No. 3 valve body solenoid is de-energized, solenoid plunger moves away from seat. This opens the drain port and releases line pressure. When No. 3 valve body solenoid is energized, the plunger closes the drain port.

NOTE: For valve body solenoid usage, see VALVE BODY SOLENOID APPLICATION table.

VALVE BODY SOLENOID APPLICATION (1)

|

Shifter Position "D" (Drive) |

No. 1 Solenoid |

No. 2 Solenoid |

|

2nd Gear |

ON |

.............. ON |

|

3rd Gear |

OFF |

ON |

|

4th Gear |

OFF |

OFF |

|

" 3 " |

ON |

OFF |

|

2nd Gear |

ON |

.............. ON |

|

3rd Gear |

OFF |

ON |

|

"1-2" |

ON |

OFF |

|

2nd Gear |

ON |

.............. ON |

|

"R" (Reverse) |

ON |

OFF |

|

"N" Or "P" |

ON |

OFF |

(1) - Valve body contains 3 valve body solenoids. See Fig. 2. No. 1 and 2 valve body solenoids are used for controlling transmission shifts. No. 3 valve body solenoid is used for torque converter lock-up only.

92F13511

Fig. 2: Identifying Valve Body Solenoids Courtesy of Chrysler Corp.

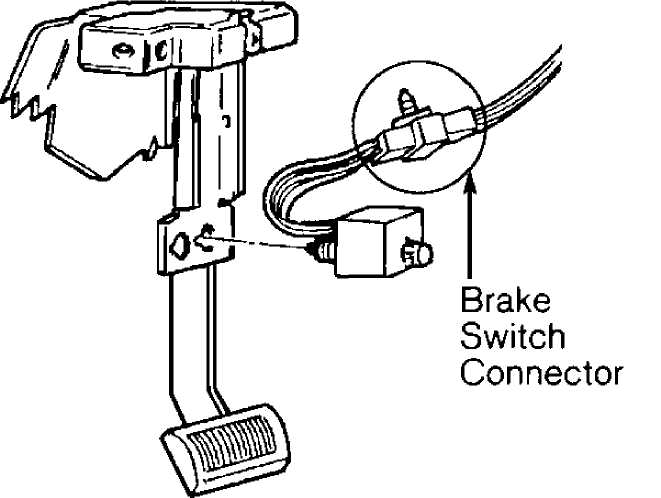

BRAKE SWITCH

Brake switch is an input device mounted above the brake pedal. When brake pedal is operated, brake switch delivers an input signal to the TCM. The TCM uses input signal for controlling No. 3 valve body solenoid for torque converter lock-up.

NEUTRAL SAFETY SWITCH

NOTE: Neutral safety switch may be referred to as park/neutral safety switch or gear select switch.

Neutral safety switch is an input device mounted on the transmission manual valve shaft. Neutral safety switch delivers an input signal to TCM, indicating transmission manual valve gear position.

SPEED SENSOR

Speed sensor, mounted in adapter housing or extension

housing, is an input device consisting of speed sensor rotor and speed sensor. Speed sensor rotor is mounted on transmission output shaft. Input signal is delivered from speed sensor to TCM with each revolution of transmission output shaft. The TCM uses input signal for controlling transmission operation.

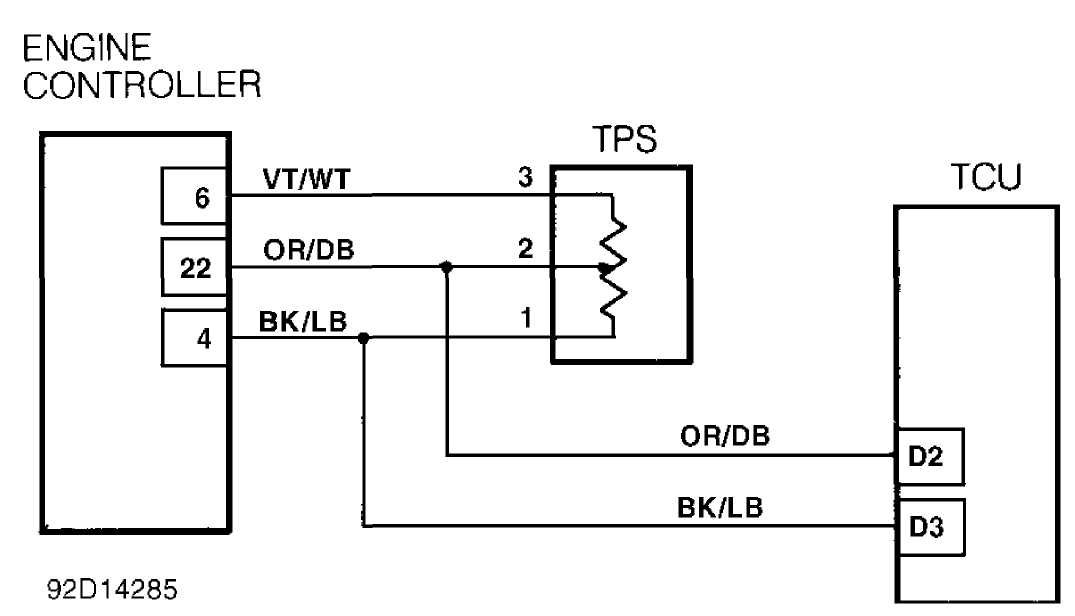

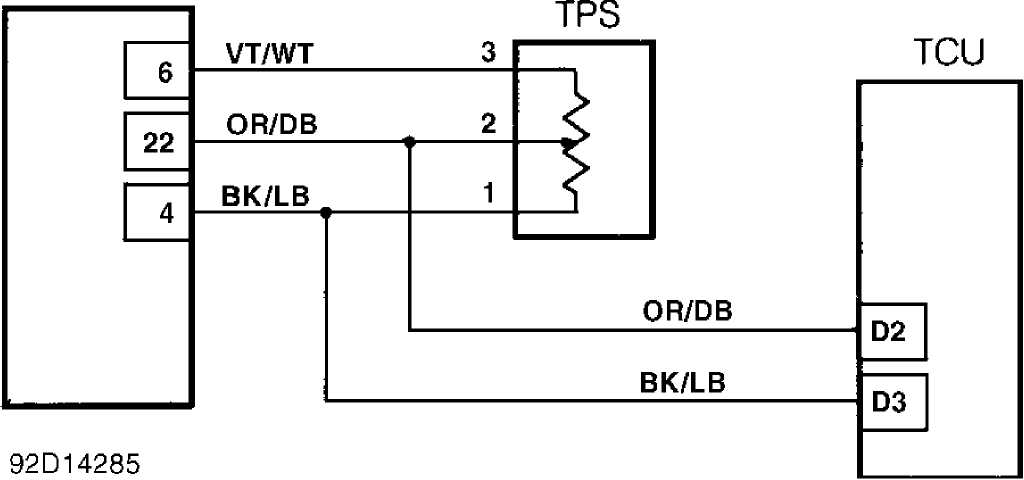

THROTTLE POSITION SENSOR (TPS)

The TPS, mounted on throttle body, determines throttle position and delivers an input signal to TCM. The TCM uses input signal for controlling transmission upshifts and torque converter lock-up.

SELF-DIAGNOSTIC SYSTEM

DIAGNOSTIC PROCEDURE

When performing vehicle diagnosis:

Ensure transmission fluid level is correct and fluid is neither

contaminated nor aerated.

Ensure shift cable is properly adjusted. Refer to the appropriate

TRANSMISSION SERVICING - A/T article in this section.

Ensure battery is fully charged.

Perform visual inspection, ensuring all electrical connections at

transmission, TCM, throttle position sensor, neutral safety

switch, speed sensor and brake switch are clean and properly

installed.

Perform TEST 1A - VERIFICATION OF COMPLAINT under TROUBLE

SHOOTING CHARTS in this article.

Repair diagnostic trouble codes in order displayed.

Always perform TEST 2A - VERIFICATION TEST after repair is

completed. See TEST 2A - VERIFICATION TEST under TROUBLE

SHOOTING CHARTS in this article.

RETRIEVING DIAGNOSTIC TROUBLE CODES

NOTE: Manufacturer recommends using ChryslerÆs Diagnostic Readout Box-II (DRB-II) with proper cartridge for system diagnosis. Other after-market scan tools may be used for system diagnosis. The following procedure is for DRB-II scan tool usage. Use manufacturerÆs instruction for operating the DRB-II scan tool. When retrieving diagnostic trouble codes

using DRB-II, you must first enter AW4 MENU and then retrieve diagnostic trouble codes.

NOTE: Ensure TEST 1A - VERIFICATION OF COMPLAINT is performed when trouble shooting the vehicle. This test checks for diagnostic trouble codes with vehicle stationary and during road test. See TEST 1A - VERIFICATION OF COMPLAINT under TROUBLE SHOOTING CHARTS.

NOTE: The DRB-II scan tool can be used in several different modes using manufacturerÆs instructions to activate system components and perform several tests on transmission. See DRB-II OPERATING MODES.

Entering AW4 MENU

1) Ensure ignition is off. Connect DRB-II to 6-pin

94F38427

Fig. 3: Diagnostic Connector Courtesy of Chrysler Corp.

& Terminals I.D. (Cherokee)

transmission diagnostic connector. See Fig. 3. Transmission diagnostic connector is located on driverÆs side of instrument panel, above accelerator pedal.

transmission diagnostic connector. See Fig. 3. Transmission diagnostic connector is located on driverÆs side of instrument panel, above accelerator pedal.

2) Turn ignition on. Copyright date and diagnostic program will be briefly displayed. If DRB-II displays an error message, proceed to DRB-II PROBLEMS & ERROR MESSAGES. The following are possible error messages that may appear.

CARTRIDGE ERROR HIGH BATTERY

KEYPAD TEST FAILURE

LOW BATTERY

RAM TEST FAILURE

If no error messages appear, display will read as follows

after a few seconds: 1) VEHICLES TESTED, 2) HOW TO USE, 3) CONFIGURE

and 4) SELECT SYSTEM.

Select 4) SELECT SYSTEM to enter diagnostic system. Once

in SELECT SYSTEM, select 2) TRANSMISSION to enter transmission.

Display will read 1) EATX and 2) AW4.

Select 2) AW4. After a few seconds display will change to

read AW4, VERSION 01. After a few seconds, display will read AW4 MENU,

1) SYSTEM TEST and 2) READ FAULTS. If DOWN ARROW is depressed 3 times,

display will read as follows: 3) STATE DISPLAY, 4) ACTUATOR TESTS and

5) ADJUSTMENTS.

NOTE: The ACTUATOR TESTS and ADJUSTMENTS cannot be used when diagnosing the AW-4 transmission.

Retrieving Diagnostic Trouble Codes

Select 2) READ FAULTS from AW4 MENU. If no diagnostic

trouble code exists, display will read as follows: AW4 FAULTS, NO

FAULTS DETECTED.

If diagnostic trouble code exists, the following message

will be displayed: 1 OF 3 FAULTS. This number will vary depending on

number of diagnostic trouble codes stored in the TCM memory.

Diagnostic trouble code and message will be displayed.

Press DOWN ARROW key to display next diagnostic trouble code. To

identify diagnostic trouble code, see

DIAGNOSTIC TROUBLE CODE IDENTIFICATION table.

NOTE: See TROUBLE SHOOTING CHARTS to diagnose faults indicated by trouble codes.

NOTE: Valve body solenoid diagnostic trouble code 700 may appear in a FAULT PRESENT or FAULT STORED status. Status will be displayed along with diagnostic trouble code. Diagnostic trouble code must be diagnosed depending on the status. See TEST 1A - VERIFICATION OF COMPLAINT under TROUBLE SHOOTING CHARTS.

DIAGNOSTIC TROUBLE CODE IDENTIFICATION

Trouble Code Problem Area

700 (1) Valve Body Solenoid

702 Speed Sensor

703 (2) Gear Select Switch

705 Throttle Position Sensor

706 Brake Switch

707 Wrong TCM Or TCU

(1) - Trouble code may apply to individual valve body solenoids. Valve

body solenoid may be referred to as S1 for No. 1, S2 for No. 2 and S3

for No. 3.

(2) - Gear select switch is the same as the neutral safety switch.

CLEARING DIAGNOSTIC TROUBLE CODES

1) Once all diagnostic trouble codes have been obtained, diagnostic trouble code(s) can be erased from TCM memory by disconnecting electrical connector from TCM for at least 15 seconds.

CAUTION: DO NOT disconnect battery, as data stored in other vehicle control modules will be lost.

2) The TCM is located behind right side of instrument panel on Cherokee. See Fig. 1.

DRB-II OPERATING MODES

NOTE: The DRB-II can be operated in several different modes

to perform various tests. Except for voltmeter/ohmmeter and HOW TO USE modes, all other operating modes are selected from AW4 MENU. See ENTERING AW4 MENU under RETRIEVING DIAGNOSTIC TROUBLE CODES .

VOLTMETER/OHMMETER MODE

To access voltmeter/ohmmeter mode, connect Red volt-ohmmeter test lead to Red port at top right corner of DRB-II. There are 2 different ports on top of DRB-II; ensure test lead is connected to proper port. Access voltmeter or ohmmeter mode using manufacturerÆs instructions.

NOTE: The DRB-II is grounded through transmission diagnostic connector and only one test lead is required. When diagnosing transmission, an external volt-ohmmeter may sometimes be required.

HOW TO USE MODE

This mode gives instructions on DRB-II usage. To enter

this mode, see steps 1) through 4) of ENTERING AW4 MENU under

RETRIEVING DIAGNOSTIC TROUBLE CODES. Select 2) HOW TO USE.

A series of screens will be displayed explaining DRB-II

key usage for system diagnosing.

SYSTEM TEST MODE

NOTE: SYSTEM TEST mode consists of a stationary test and a road test. The SYSTEM TEST mode must be selected from AW4 MENU. Refer to ENTERING AW4 MENU under RETRIEVING DIAGNOSTIC TROUBLE CODES .

Stationary test monitors transmission system data, current

valve body solenoid failures, switch failures, correct TCM

application, calibration and operation. Road test checks all valve

body solenoids and speed sensor.

Technician will be instructed to place shift lever in each

gear position, starting by shifting into 1-2 position. Once

transmission is in Park, brake pedal must be depressed to check brake

switch.

After brake switch is checked, technician will be

instructed to slowly depress throttle. DRB-II will display 7 asterisks (*******) corresponding to throttle position. While depressing accelerator, Throttle Position Sensor (TPS) sweeps through entire range of positions required by the TCM.

A corresponding asterisk will be cleared from DRB-II

display as each throttle position is sensed by TCM. Several attempts

may be required to clear all asterisks from the display, depending on

how fast accelerator is depressed.

After throttle position is checked, technician will be

instructed to drive the vehicle. The DRB-II will indicate if a

requested action is seen by the TCM. If technician is requested to perform a particular operation and TCM does not acknowledge the action, press ENTER key to continue testing.

The TCM will instruct technician to accelerate vehicle at

light throttle to ensure transmission shifts through all gears,

indicating proper valve body solenoid operation.

During road test, ensure vehicle can be accelerated slowly

and evenly to allow transmission to enter all gear ranges without

downshifting or braking. If a failure is sensed, a diagnostic trouble

code will be displayed on DRB-II.

NOTE: If TCM senses a failure, control logic activates a specified valve body solenoid to obtain a certain gear depending on failure. Because transmission diagnostic trouble codes are displayed one at a time, multiple diagnostic trouble codes must be identified by retesting transmission.

STATE DISPLAY MODE

NOTE: STATE DISPLAY mode must be selected from AW4 MENU. See

ENTERING AW4 MENU under RETRIEVING DIAGNOSTIC TROUBLE CODES . Select 3) STATE DISPLAY on DRB-II.

Module Information

When selecting module information option, the TCM version will be indicated by a 2-digit number. Information can be used to verify proper TCM application.

Sensor

When selecting sensor option, TPS and RPM indications will

be shown. The TPS indicator will display a 7 segment bar graph,

indicating TPS position and throttle plate angle.

A properly operating TPS should indicate 7 segments

through full throttle travel. The RPM indicator will display

transmission output shaft revolutions per minute.

Brake Switch Or Input/Output

Display indicates brake switch status, indicating whether brake pedal is applied or released. Display also indicates shift lever position, whether a valve body solenoid is on or off and present transmission operating gear.

DRB-II PROBLEMS & ERROR MESSAGES

CARTRIDGE ERROR

If CARTRIDGE ERROR message is displayed, disconnect DRB-II

from transmission diagnostic connector. DO NOT touch keys on DRB-II

keypad. Reconnect DRB-II to transmission diagnostic connector and note

display.

If CARTRIDGE ERROR message is displayed, replace DRB-II

cartridge and proceed with diagnostics. If KEYPAD TEST FAILURE message

is displayed, replace DRB-II and proceed with diagnostics.

HIGH BATTERY

If HIGH BATTERY message is displayed, use external voltmeter to check battery voltage at battery terminals. If battery voltage is 11.7-13.0 volts, replace DRB-II. If battery voltage is not 11.7-13.0 volts, check charging system.

KEYPAD TEST FAILURE

If KEYPAD TEST FAILURE message is displayed, disconnect

DRB-II from transmission diagnostic connector. DO NOT touch keys on

DRB-II keypad. Reconnect DRB-II to transmission diagnostic connector

and note display.

If KEYPAD TEST FAILURE message is not displayed, proceed

with diagnostics. If KEYPAD TEST FAILURE message is displayed, replace

DRB-II and proceed with diagnostics.

LOW BATTERY

If LOW BATTERY message is displayed, use external voltmeter to check battery voltage at battery terminals. If battery voltage is 11.7-13.0 volts, replace DRB-II. If battery voltage is not 11.7-13.0 volts, check charging system.

RAM TEST FAILURE

If RAM TEST FAILURE message is displayed, disconnect DRB-

II from transmission diagnostic connector. DO NOT touch keys on DRB-II

keypad. Reconnect DRB-II to transmission diagnostic connector and note

display.

If RAM TEST FAILURE message is not displayed, proceed with

diagnostics. If RAM TEST FAILURE message is displayed, replace DRB-II

and proceed with diagnostics. If KEYPAD TEST FAILURE message is

displayed, replace DRB-II and proceed with diagnostics.

COMPONENT TESTING

BRAKE SWITCH TEST

Brake switch is mounted above brake pedal. When brake pedal is operated, brake switch delivers an input signal to TCM. The TCM uses input signal for controlling No. 3 valve body solenoid for torque converter lock-up. No other information is available from manufacturer.

NOTE: For proper brake switch adjustment, see BRAKE SWITCH R & I under REMOVAL & INSTALLATION.

NEUTRAL SAFETY SWITCH TEST

NOTE: Neutral safety switch may be referred to as park/neutral or gear select switch. For proper neutral safety switch adjustment, see NEUTRAL SAFETY SWITCH R & I under REMOVAL & INSTALLATION.

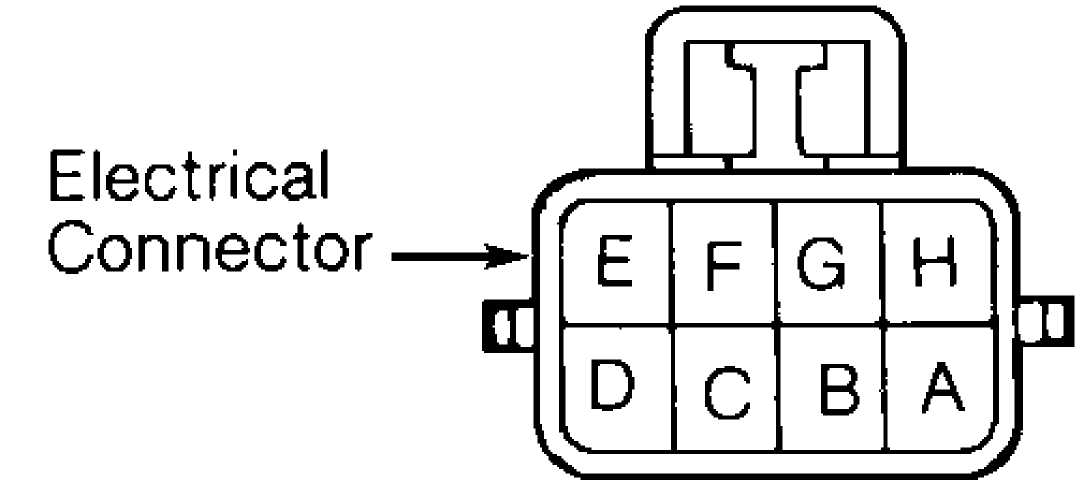

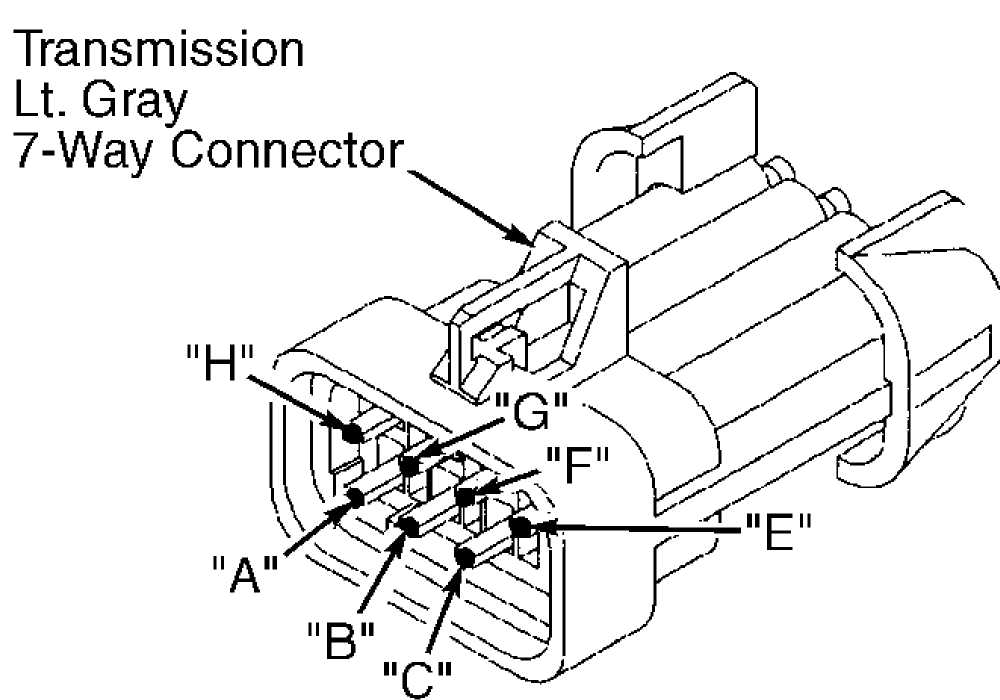

Disconnect electrical connector. Note terminal

identification. See Fig. 4. Using ohmmeter, check continuity between specified terminals in relation to shift lever position. See the NEUTRAL SAFETY SWITCH CONTINUITY SPECIFICATIONS table. Replace neutral safety switch if continuity is not as specified.

NEUTRAL SAFETY SWITCH CONTINUITY SPECIFICATIONS

Shift Lever Position Continuity Between Terminals

Park "B" & "C"

Reverse "A" & "E"

Neutral "B" & "C"

Drive ( 1)

3 "A" & "G"

1-2 "A" & "H"

(1) - No continuity should exist between any terminals.

92H13513

Fig. 4: Identifying Neutral Safety Switch Terminals Courtesy of Chrysler Corp.

SPEED SENSOR TEST

Disconnect electrical connector at speed sensor located on

adapter housing or extension housing. Connect ohmmeter leads between

speed sensor electrical terminals.

Rotate transmission output shaft and note ohmmeter

reading. Ohmmeter needle should fluctuate to indicate speed sensor

operation. Replace speed sensor if no reading is obtained.

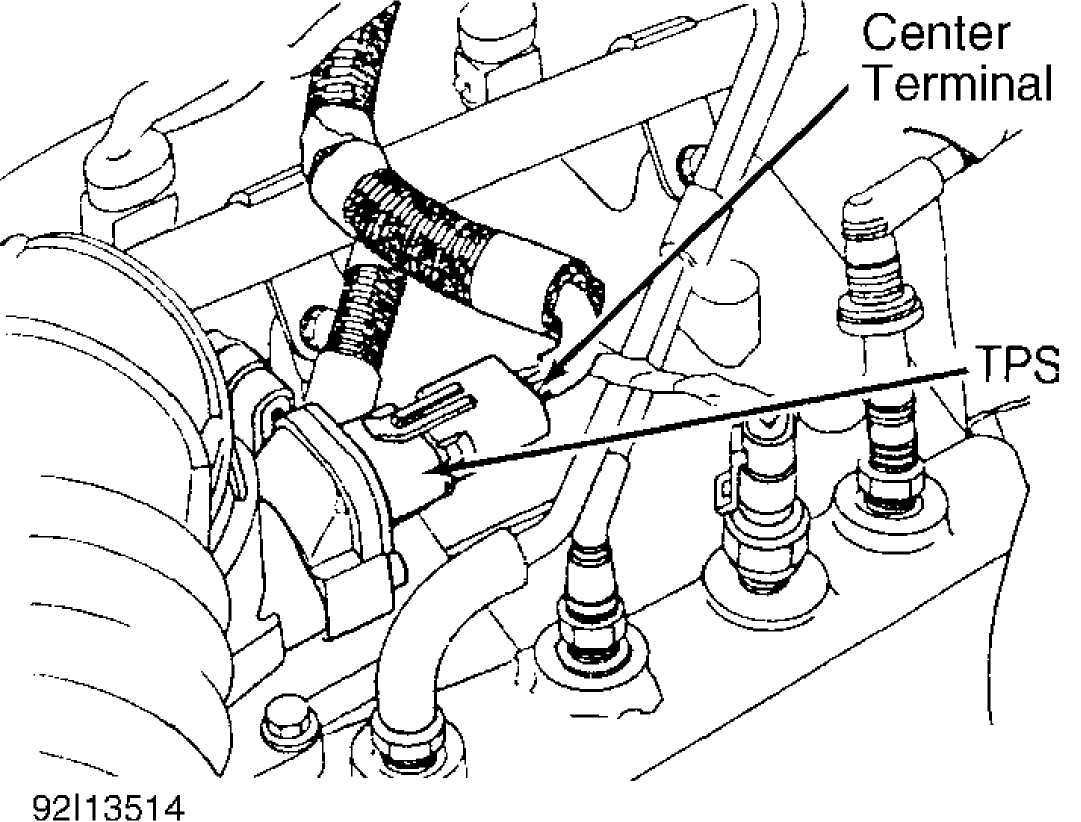

THROTTLE POSITION SENSOR (TPS) TEST

NOTE: Digital voltmeter must be used to check TPS.

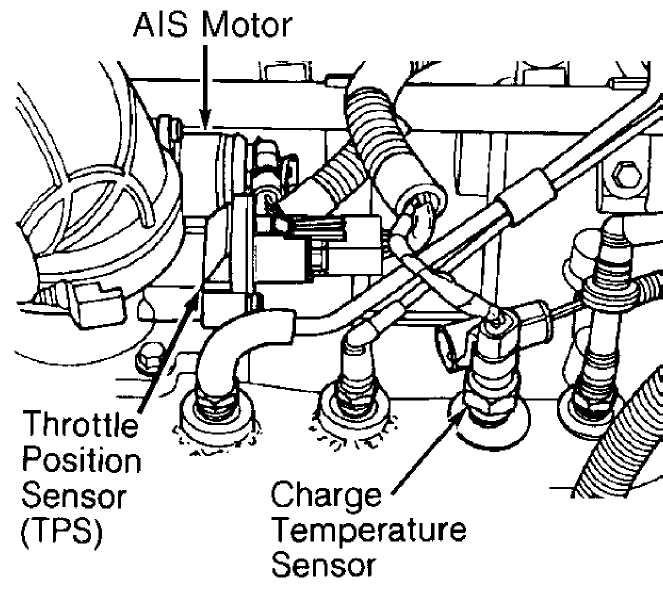

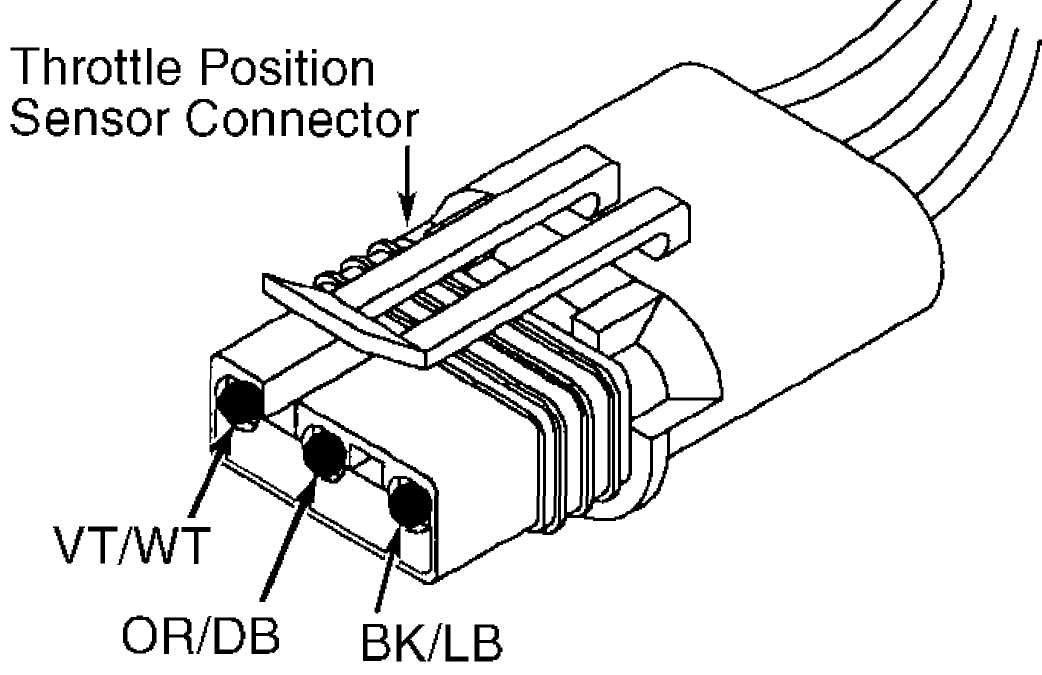

Note location of TPS electrical connector. See Fig. 5.

Turn ignition on. Using digital voltmeter, check output voltage at

center terminal with throttle plate closed (idle position) and wide

open (full throttle).

With throttle plate closed (idle position), output voltage

should be greater than 200 millivolts. With throttle plate wide open

(full throttle), output voltage should be less than 4.8 volts.

Ensure output voltage gradually increases as throttle

plate is moved from closed to wide open throttle. If no voltage

exists, check for defective wiring circuits or connections. Replace

TPS if defective.

92113514

Fig. 5: Identifying TPS Electrical Connector Courtesy of Chrysler Corp.

VALVE BODY SOLENOID TEST

With oil pan removed, disconnect electrical connector from valve body solenoid. Using ohmmeter, check resistance between valve body solenoid electrical terminal and solenoid mounting bracket. Replace valve body solenoid if resistance is not 11-15 ohms.

TROUBLE SHOOTING CHARTS & CODE CHARTS

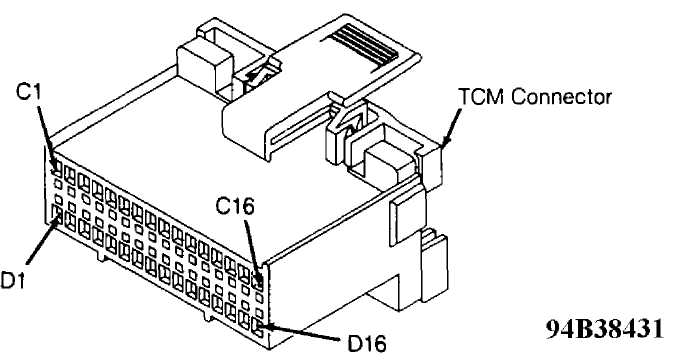

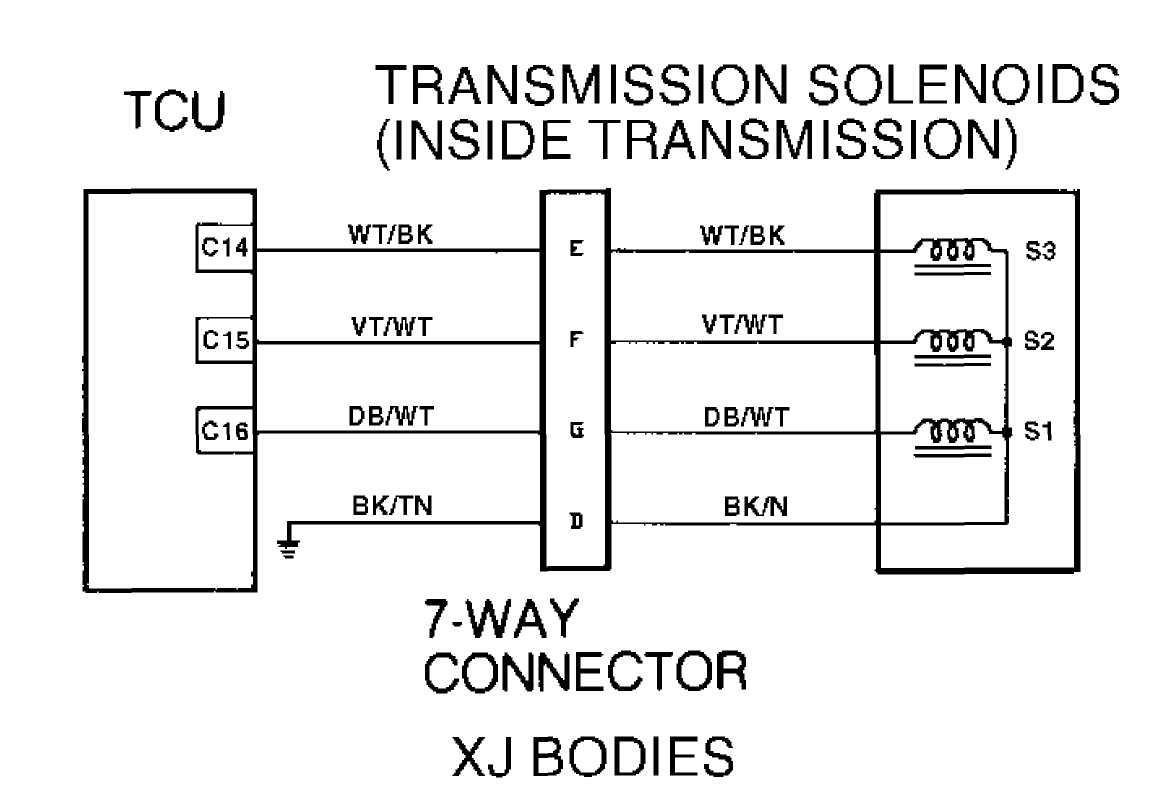

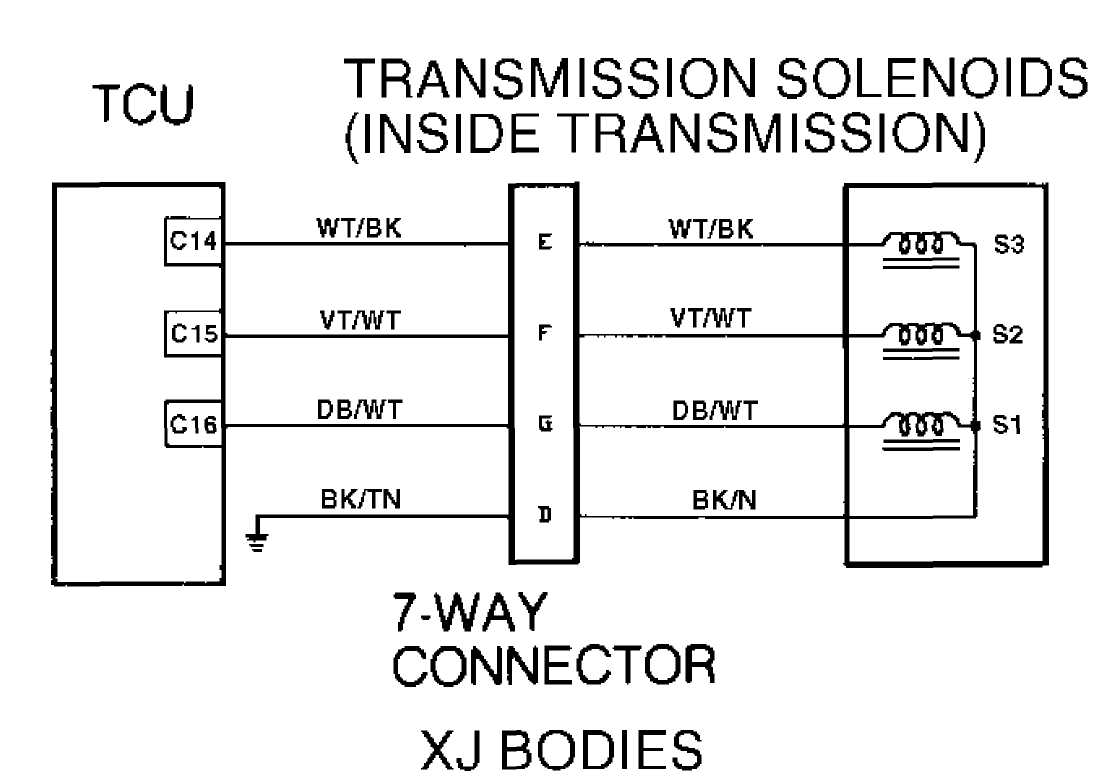

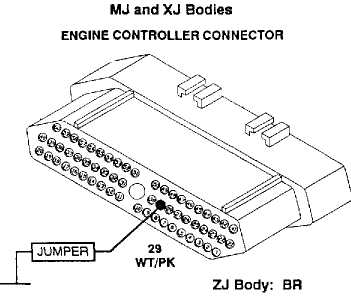

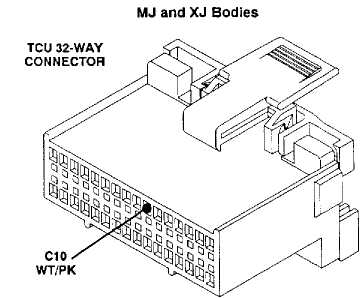

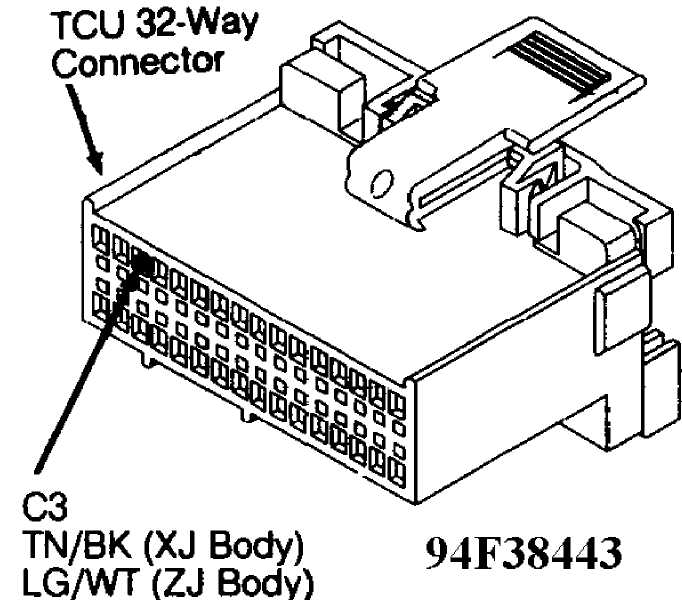

NOTE: Following trouble shooting charts and illustrations are courtesy of Chrysler Corp. Always start by performing TEST 1A - VERIFICATION OF COMPLAINT. When diagnosing transmission, it may be necessary to verify TCM connector terminals, circuits and function, See Fig. 6.

NOTE: When using trouble shooting charts, Transmission Control

Module (TCM) may be referred to as Transmission Control Unit (TCU). Diagnostic trouble code may be referred to as fault code. Neutral safety switch may be referred to as park/neutral or gear select switch.

CHEROKEE

CAV... CIRCUIT FUNCTION

C1-C2 Not Used

C3 505 TN/BK Trans Speed Sensor

C4 137 YL/BK Auto Trans Diagnostic

C5-C7 Not Used

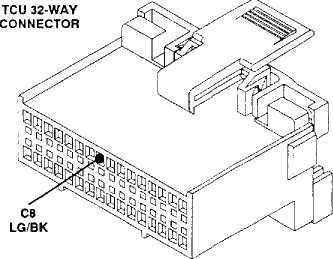

C8 506 LG/BK Low (1-2) Input

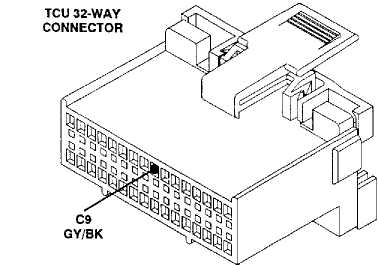

C9 507 GY/BK Drive (3) Input

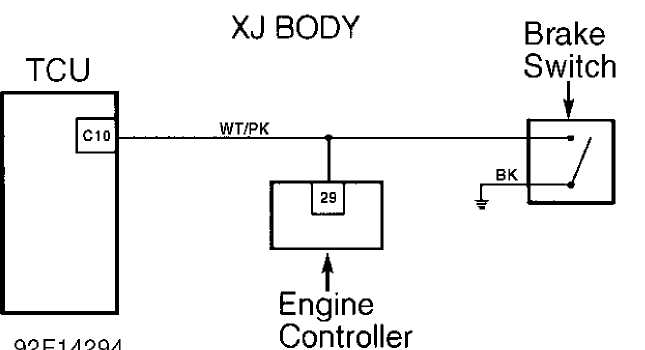

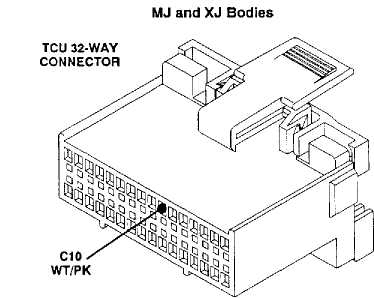

C10 K29 WT/PK Brake Input

C11 Not Used

C12-C13 Not Used

C14 508 WT/BK S3 Solenoid

(Converter Lockup)

C15 509 VT/WT S2 Solenoid

C16 510DB/WT S1 Solenoid

D1 Not Used

D2 K22 OR/DB Throttle Position Sensor

D3 K4BK/LB TPS Signal Ground

D4-D6 Not Used

D7 212BK/TN Power Ground

D8-D13 Not Used

D14 A14RD Battery

D15 Not Used

D16 T17 YL Ignition (Run/On)

: TCM Connector Terminals I.D., Circuits

Fig.

Courtesy of Chrysler Corp.

GRANDCHEROKEE

CAV... CIRCUIT FUNCTION

C1-C2 Not Used

C3 T14 LG/WT Trans Speed Sensor

C4 D82 BfVYL Auto Trans Diagnostic

C5-C7 Not Used

C8 T25 LG Low (1-2) Input

C9 T50 DG Drive (3) Input

C10 .... L53 BR Brake Input

C11-C13 Not Used

C14 .... T20 LB/BR S3 Solenoid

(Converter Lockup)

C15 .... T59 PK S2 Solenoid

C16 .... T60 BR/YL S1 Solenoid

D1 Not Used

D2 K22 OR/DB Throttle Position Sensor

D3 K4 BK/LB TPS Signal Ground

D4-D6 Not Used

D7 21 BK Power Ground

D8-D13 ,. Not Used

D14 .... A14 RD/WT Battery

D15 Not Used

D16 .... F86 LB/RD Ignition (Run/On)

& Functions

TEST 1A - VERIFICATION OF COMPLAINT

NOTE:

ALWAYS start diagnosis with the most recent code.

Begin your testing of the transmission with a thorough

visual inspection.

Connect the DRB-II to the transmission diagnostic

connector. See RETRIEVING DIAGNOSTIC TROUBLE CODES under SELF-DIAGNOSTIC SYSTEM for diagnostic connector location.

CAUTION: If the vehicle is in 3rd or OD position and feels

like it is stuck in 3rd or jumping from 2-1 or 3-1, perform TEST 10A - TESTING FOR INTERMITTENT SPEED SENSORS .

With the DRB-II, perform SYSTEM TEST. See SYSTEM TEST MODE

under DRB-II OPERATING MODES.

The DRB-II will instruct you to do some actions during the

System Test. The DRB-II will then look for the action to happen and

automatically go to the next test function. If you perform the

required action and the DRB-II does not move to the next function,

press ENTER. The DRB-II will continue the testing.

When the DRB-II states "VEHICLE DRIVE", the vehicle be

must be driven at a speed above 4 miles per hour to ensure accurate

testing of the vehicle speed sensor. Afterwards, the DRB-II will

display any fault codes that may be present.

When the system test is complete, if there are any fault

codes present, the DRB-II will automatically display the code(s).

There are two types of faults for the transmission

solenoids. They are displayed as "FAULT STORED" and "FAULT PRESENT". Note that the tests are different in the chart below.

8) Perform the tests shown below in response to the indicated

fault codes.

NOTE: ALWAYS start diagnosis with the most recent code.

CODE-TO-TEST MENU

CODE-TO-TEST MENU

|

Code: |

Solenoid Affected: |

Fault |

Status: |

Perform: |

||

|

None |

None Affected |

No Faults |

TEST |

2A |

||

|

700 |

Solenoid No. |

1 |

Fault |

Present |

TEST |

4A |

|

700 |

Solenoid No. |

1 |

Fault |

Stored |

TEST |

ąŚąÉ |

|

700 |

Solenoid No. |

2 |

Fault |

Present |

TEST |

4B |

|

700 |

Solenoid No. |

2 |

Fault |

Stored |

TEST |

ąŚąÉ |

|

700 |

Solenoid No. |

3 |

Fault |

Present |

TEST |

4C |

|

700 |

Solenoid No. |

3 |

Fault |

Stored |

TEST |

ąŚąÉ |

|

702 |

Speed Sensor |

Fault |

ą¤ |

TEST |

5A |

|

|

703 |

Gear Select |

Fault |

I! |

TEST |

6A |

|

|

705 |

TPS Fault |

ą¤ |

TEST |

7A |

||

|

708 |

Wrong TCU |

I! |

TEST |

9A |

||

TEST 2A - VERIFICATION TEST

NOTE: Perform TEST 1A - VERIFICATION OF COMPLAINT before proceeding.

This test verifies the correct operation of the AW4

transmission. It must be performed after finding no faults using the DRB-II, and after a vehicle repair has been made.

mounted.

Turn ignition key to "OFF".

Hold the MODE key and press the ATM key on the DRB-II at

the same time to restart the DRB-II.

Turn ignition key to "ON".

Reconnect all previously disconnected connectors.

Verify that the AW4 transmission control unit is properly

Make sure the transmission fluid is at the proper level.

Check the fluid with the transmission temperature hot, the vehicle on

level ground, and the gear selector in neutral.

If any repairs have been made, test the vehicle as

instructed in TEST 1A - VERIFICATION OF COMPLAINT., and read the

faults using the DRB-II. If there are any fault messages present,

repeat TEST 1A - VERIFICATION OF COMPLAINT.

TEST 3A - STORED DIAGNOSTIC TROUBLE CODES TEST

NOTE: Perform TEST 1A - VERIFICATION OF COMPLAINT before proceeding.

At this point, the Visual Inspection has been performed, a

"FAULT STORED" code has been found and the vehicle has been test

driven. The fault code is not "FAULT PRESENT", so it cannot be

considered a CURRENT or HARD fault.

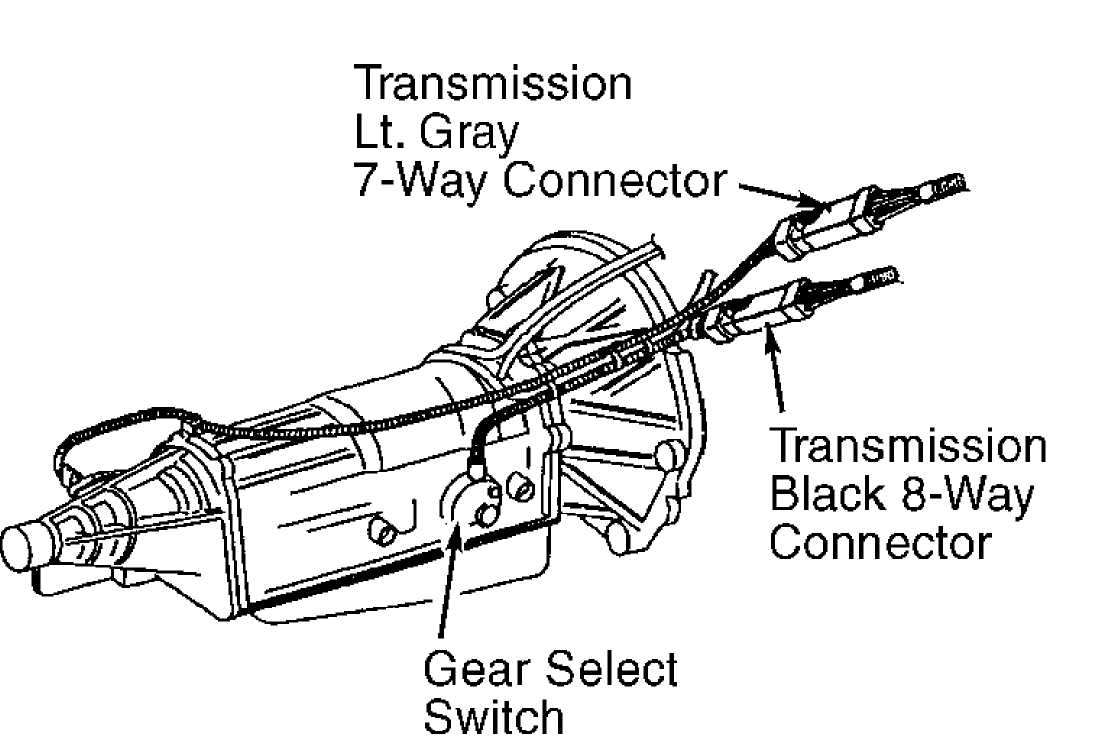

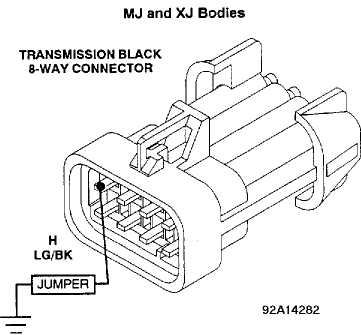

All solenoid circuits are in the same harness and a common

ground wire is used for the solenoids. Use the following figures to

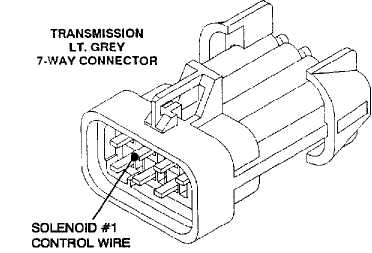

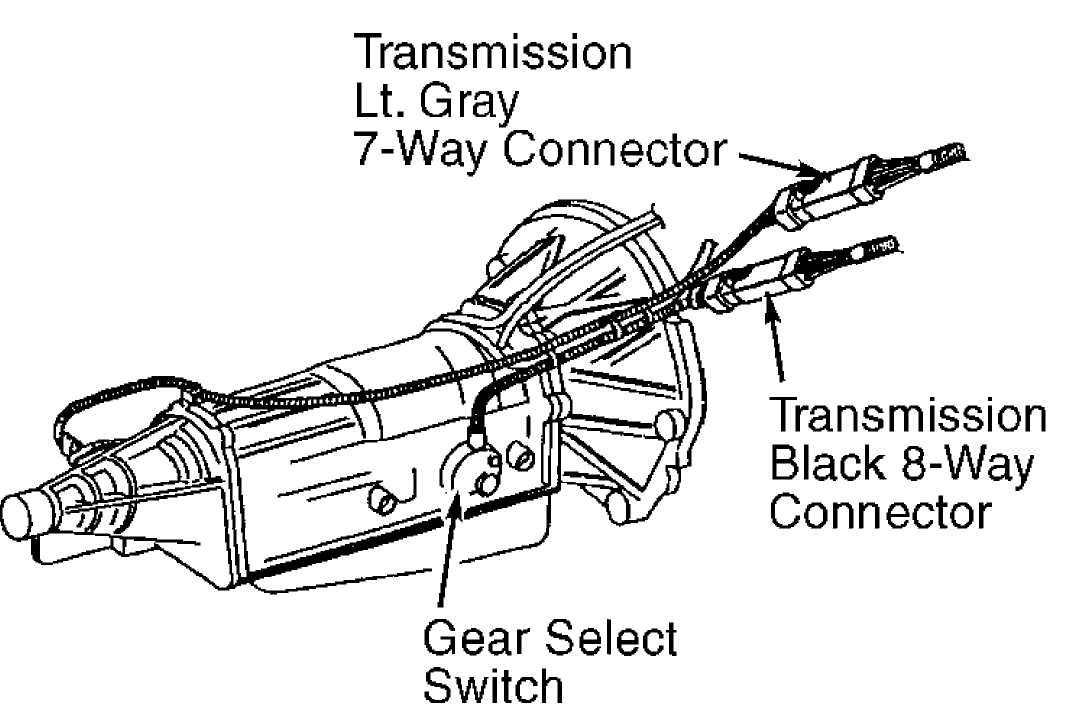

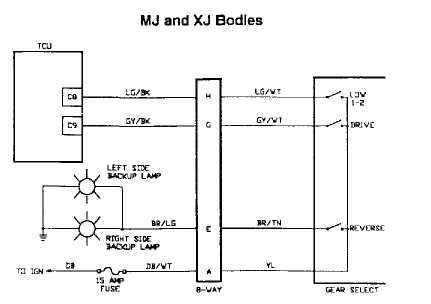

identify the harness and connector to inspect. See Fig. 7 and 8. if

all 3 solenoid faults are present, repair the Black wire (Cherokee)

ground wire open condition.

Carefully inspect the entire suspected circuit. Pay

particular attention to connectors, corrosion, accident damage, and

improper or missing parts.

If any problems are found, make the appropriate repair.

Then perform TEST 1A using the DRB-II.

Erase fault codes.

If no problems are found, perform the SYSTEM TEST using

the DRB-II. Re-check for fault codes. If there are no fault codes,

perform TEST 2A - VERIFICATION TEST. If fault code(s) return, perform

TEST 1A - VERIFICATION OF COMPLAINT.

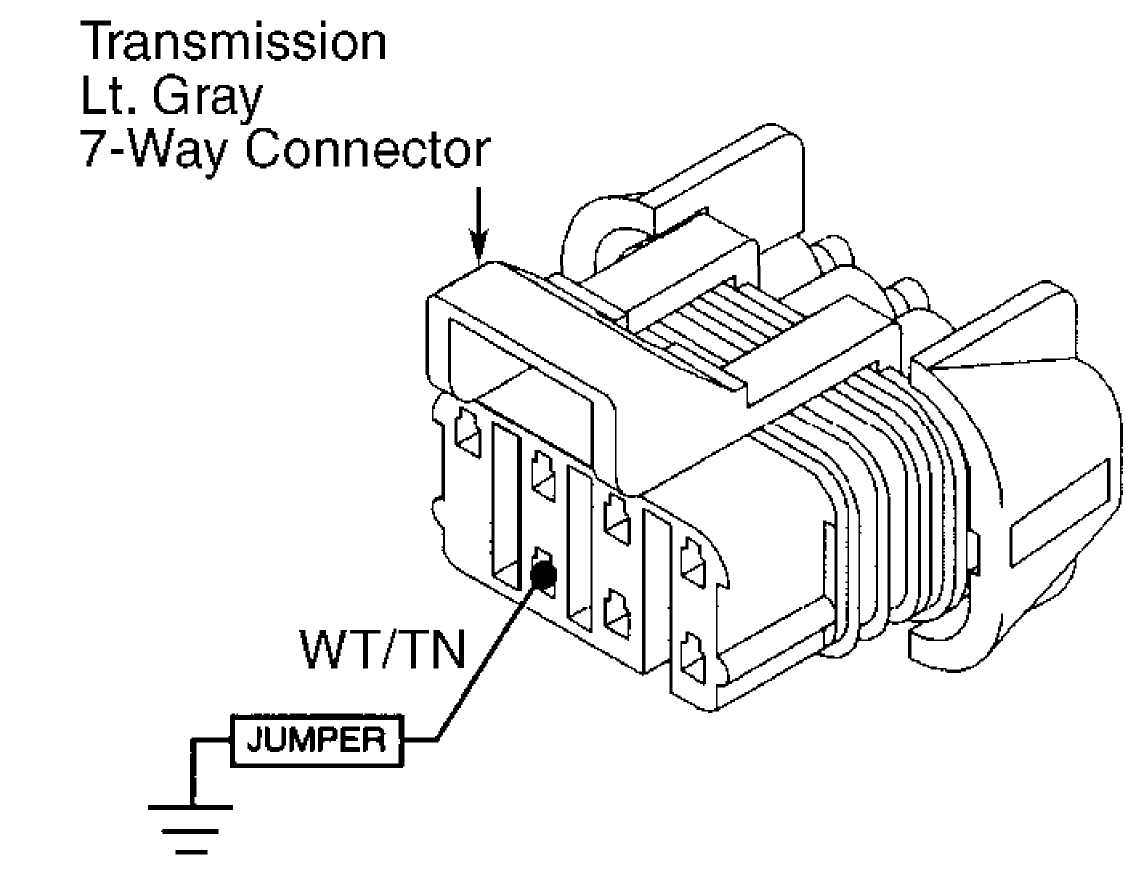

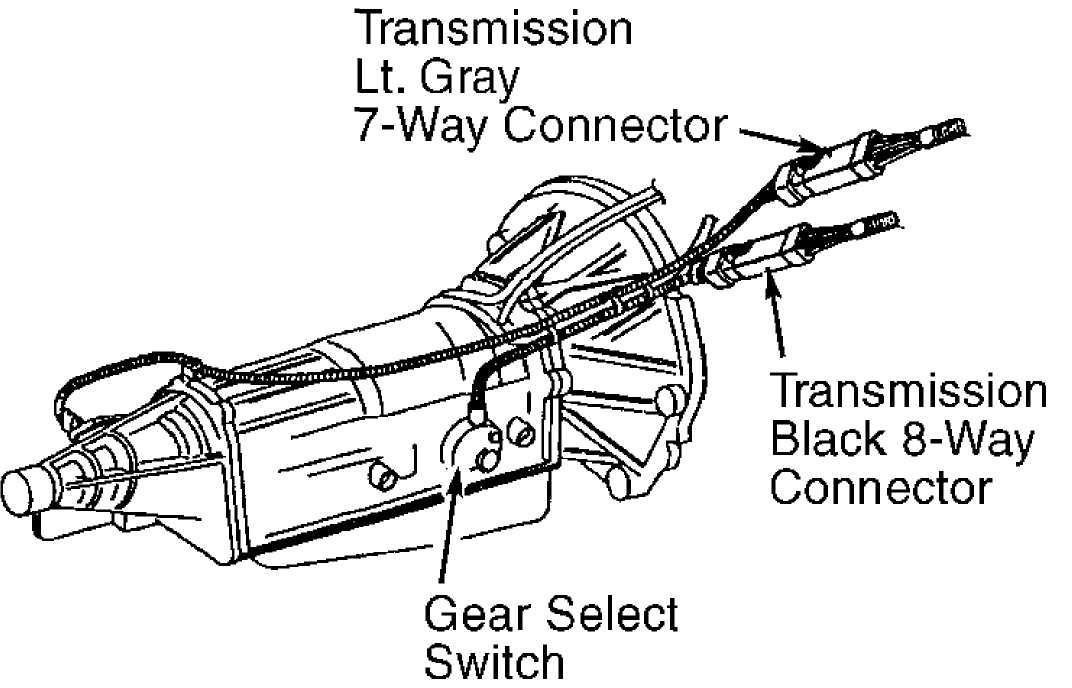

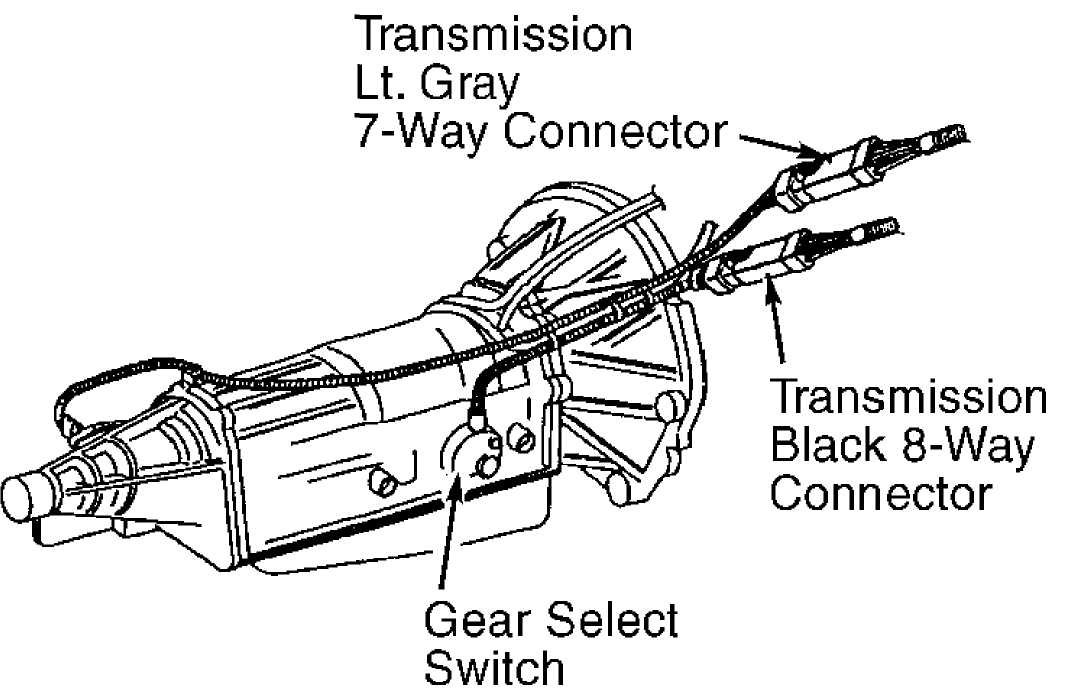

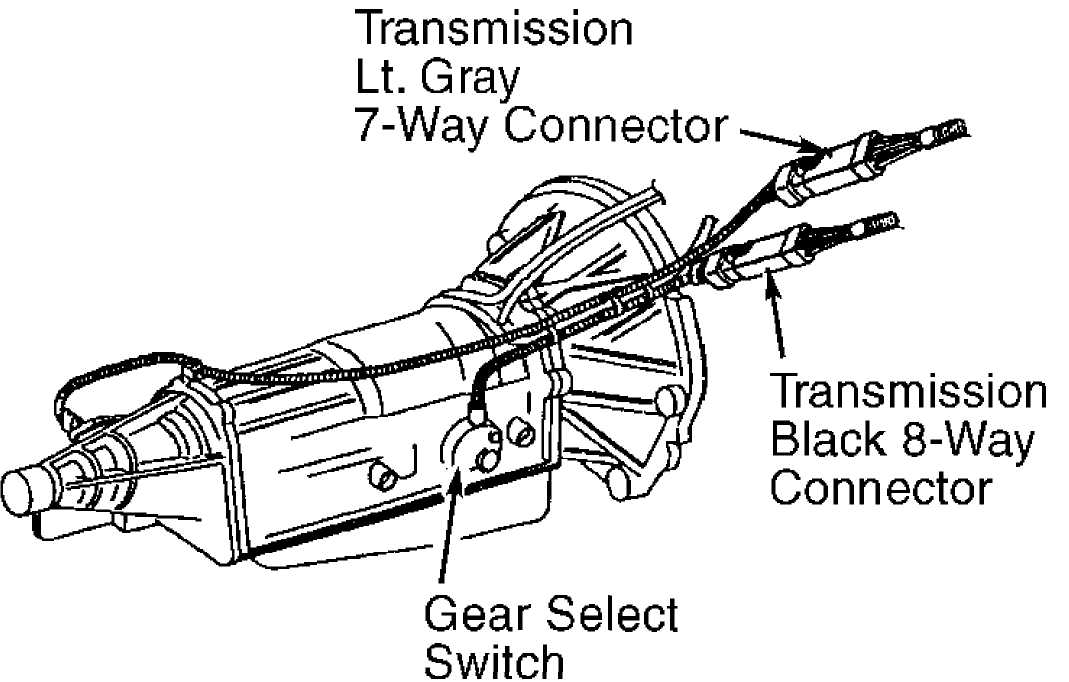

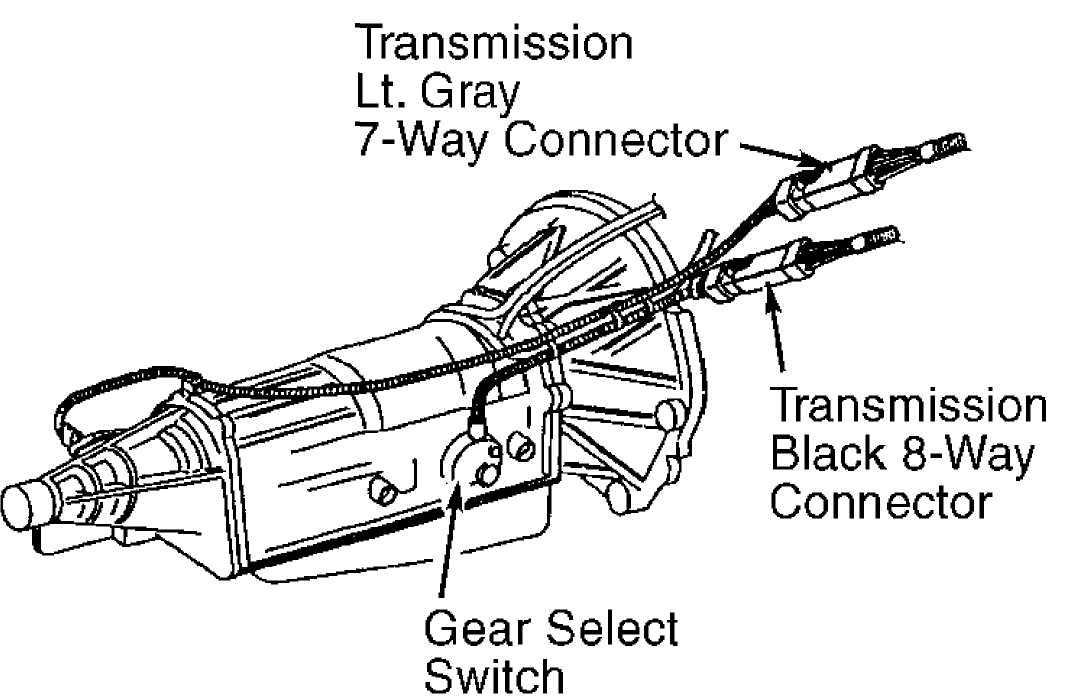

Transmission

Transmission

Lt. Gray

Gear Select Switch

Location of 7-Way Connector

92F13594

Fig. 7: Test 3A

7-Way Connector-

|

A |

B |

ąĪ |

E |

F |

G |

H |

|

BK/YL |

BK/TN |

TfSl/WT |

WT/BK |

VTAVT |

DB/WT |

BK/RD |

92G13595

Fig. 8: Test 3A - View of 7-Way Connector (Cherokee)

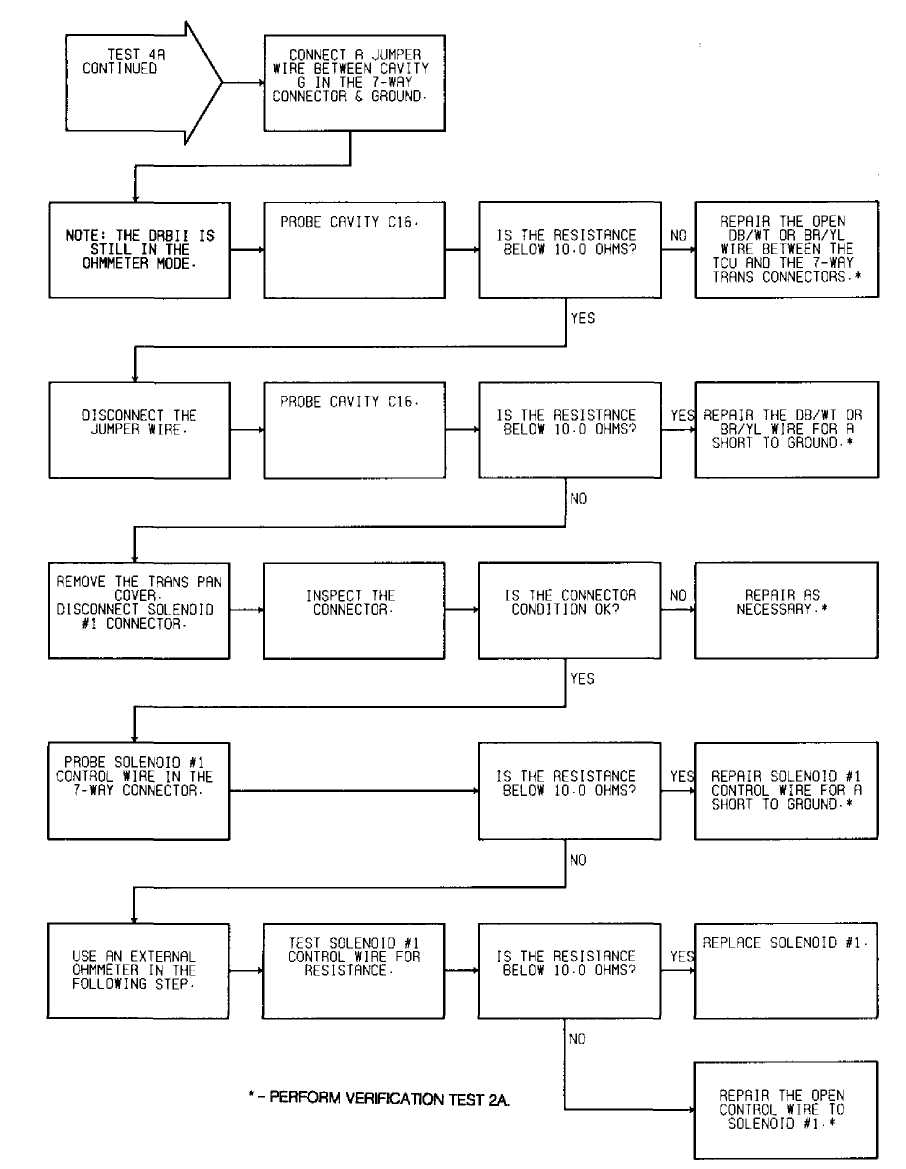

TEST 4A - CODE 700 - S1 SOLENOID CIRCUIT

Perform TEST 1A before proceeding.

Fig. 9: Test 4A - Code 700, Flow Chart (1 of 2)

92J13598

92J13598

Fig. 10: Test 4A - Code 700, Schematic (Cherokee)

Fig. 10: Test 4A - Code 700, Schematic (Cherokee)

92D13600 ZJBody: BR/YL

Fig. 11:

Test 4A - Code 700, TCU 32-Way Connector (Cavity 16)

92F13594

Fig. 12: Test 4A - Code 700, Location of 7-Way Connector

Transmission

Transmission

Lt. Gray

7-Way Connector

ąÆ

BK

BK/TN

92E13601

- Code 700, Location of Pin "B" (Ground)

Fig. 13: Test 4A

NOTE: See TEST 4A (1 OF 2) for wiring diagram.

92F13602

Fig. 14: Test 4A - Code 700, Flow Chart (2 of 2)

92J13598

92J13598

Fig. 15: Test 4A - Code 700, Schematic (Cherokee)

Transmission

Transmission

Lt. Gray

7-Way Connector

92G13603

Fig. 16: Test 4A - 7-Way Connector Cavity "G" (Cherokee)

TCU 32-WAY CONNECTOR

li

DB/WT

ZJBody: BR/YL

Fig. 17:

Test 4A - Code 700, TCU 32-Way Connector (Cavity 16)

Test 4A - Code 700, TCU 32-Way Connector (Cavity 16)

Solenoid #2

92ą?3605 Connector

Fig. 18: Test 4A - Code 700, Location of Solenoids

|

CAV |

MJ;XJ |

ZJ |

|

G |

DB/WT |

BB/YL |

Fig. 19:

92J13606

Test 4A - Code 700, Solenoid No. 1 Wire (Cavity "G")

92A13607

Fig. 20: Test 4A - Code 700, Testing S1 Control Wire

Fig. 20: Test 4A - Code 700, Testing S1 Control Wire

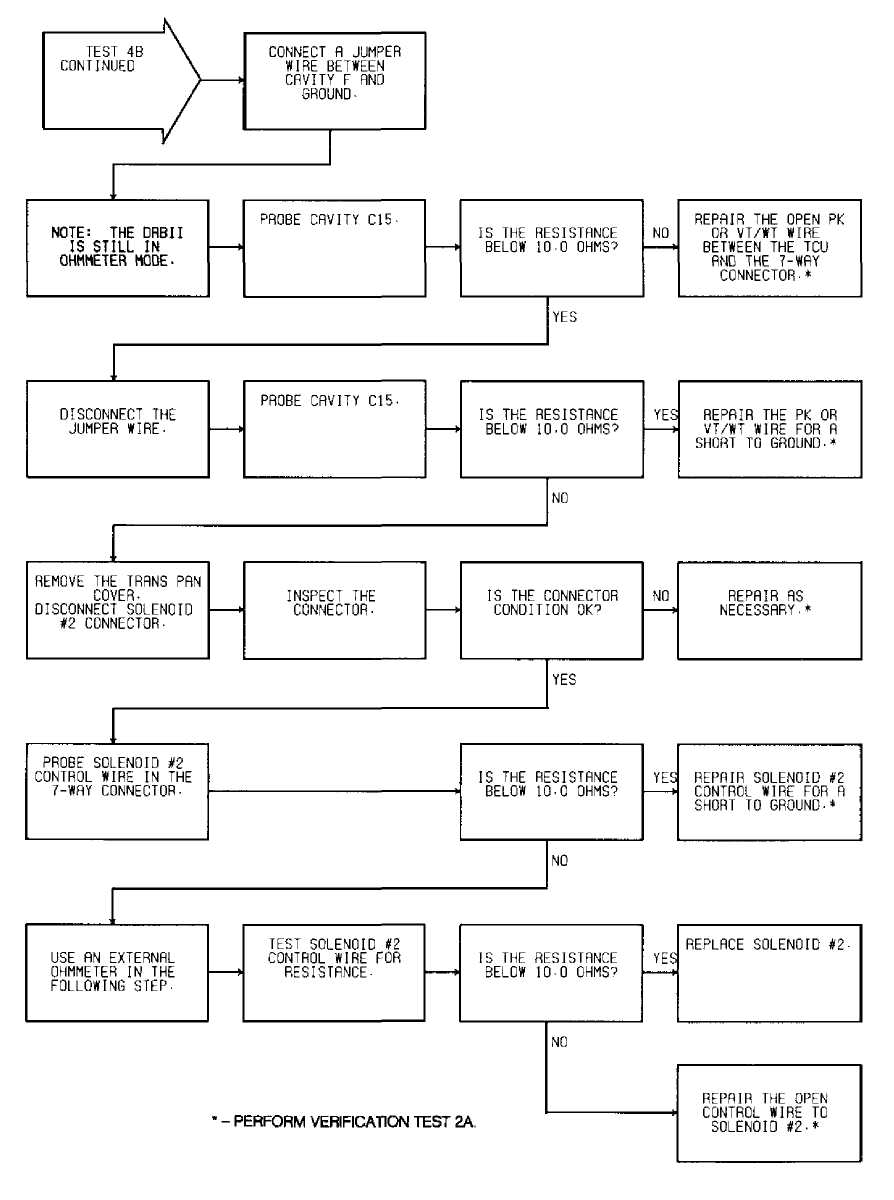

TEST 4B - CODE 700 - S2 SOLENOID CIRCUIT

Perform TEST 4A before proceeding.

92B13608 ŌĆó-PERFORM VERIFICATION TEST 2A.

Fig. 21: Test 4B - Code 700, Flow Chart (1 of 2)

92J13598

92J13598

Fig. 22: Test 4B - Code 700, Schematic (Cherokee)

|

CAV |

MJ,XJ |

ZJ |

|

C15 |

VT/WT |

PK |

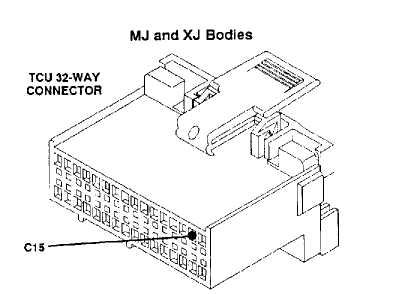

Fig. 23: Test 4B - Code 700, TCU 32-Way Connector (Cavity 15)

92F13594

Fig. 24: Test 4B - Code 700, Location of 7-Way Connector

NOTE: See TEST 4B (1 OF 2) for wiring diagram.

92F13610

Fig. 25: Test 4B - Code 700, Flow Chart (2 of 2)

92J13598

92J13598

Fig. 26: Test 4B - Code 700, Schematic (Cherokee)

Transmission

Transmission

Lt. Gray

7-Way Connector

I.

XJ BODY

92G13611

Fig. 27: Test 4B - 7-Way Connector Cavity "F" (Cherokee)

CAV MJ/XJ ZJ

C15 VTVWT PK

Fig. 28: Test 4B - Code 700, TCU 32-Way Connector (Cavity 15)

92ą?3605 Connector

92ą?3605 Connector

Fig. 29: Test 4B - Code 700, Location of Solenoids

|

CAV |

MJ/XJ |

ZJ |

|

F |

VT/WT |

PK |

Fig. 30: Test 4B - Code 700, Solenoid No. 1 Wire (Cavity "F")

Transmission

Transmission

Lt. Gray

7-Way Connector

I

92J136U Solenoid #2

92J136UConnector

Fig. 31: Test 4B - Code 700, Testing S2 Control Wire

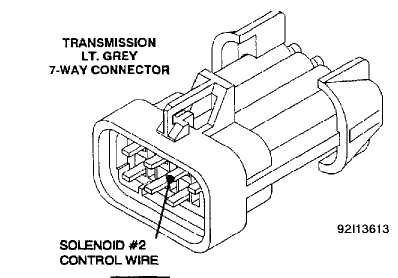

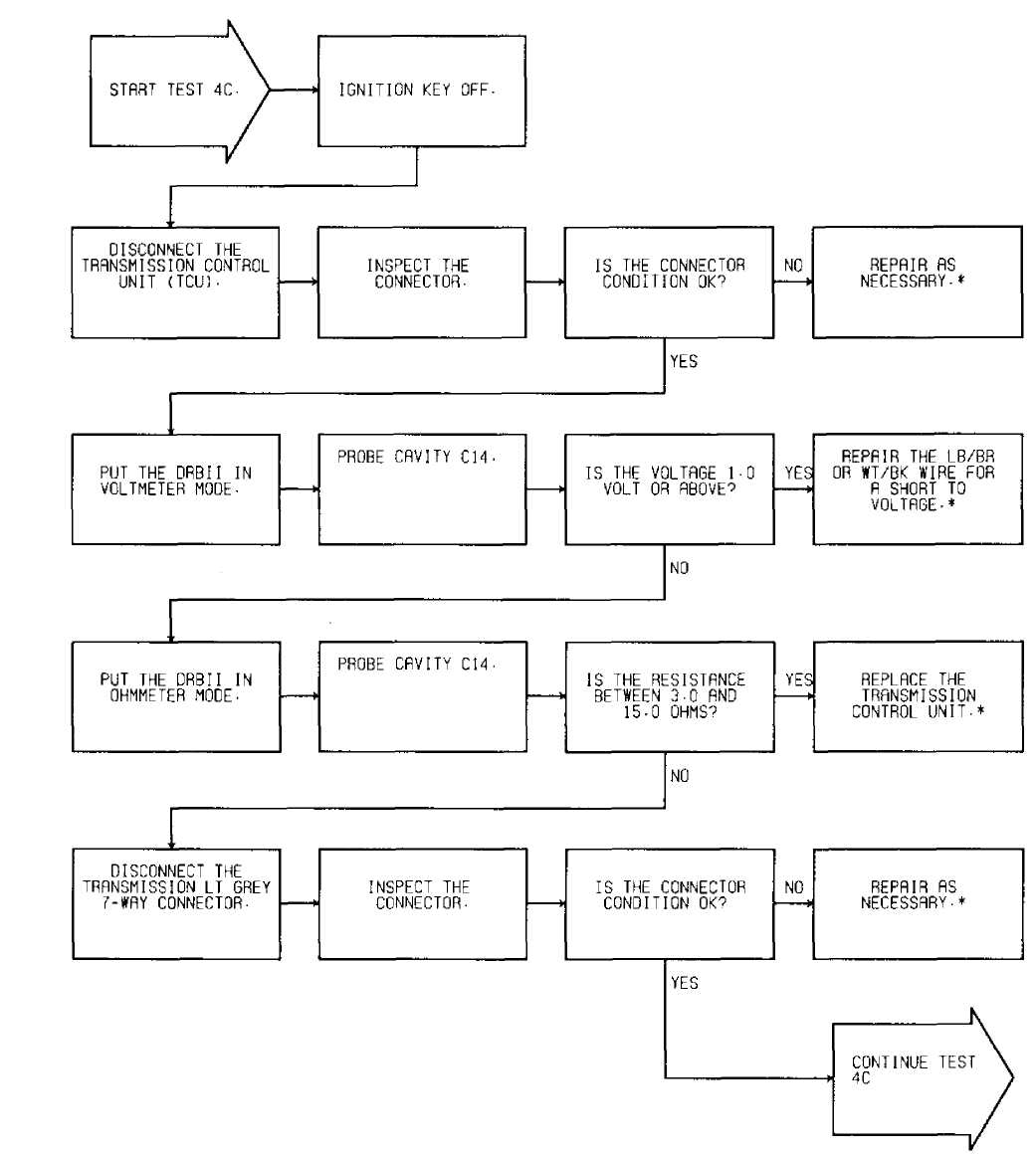

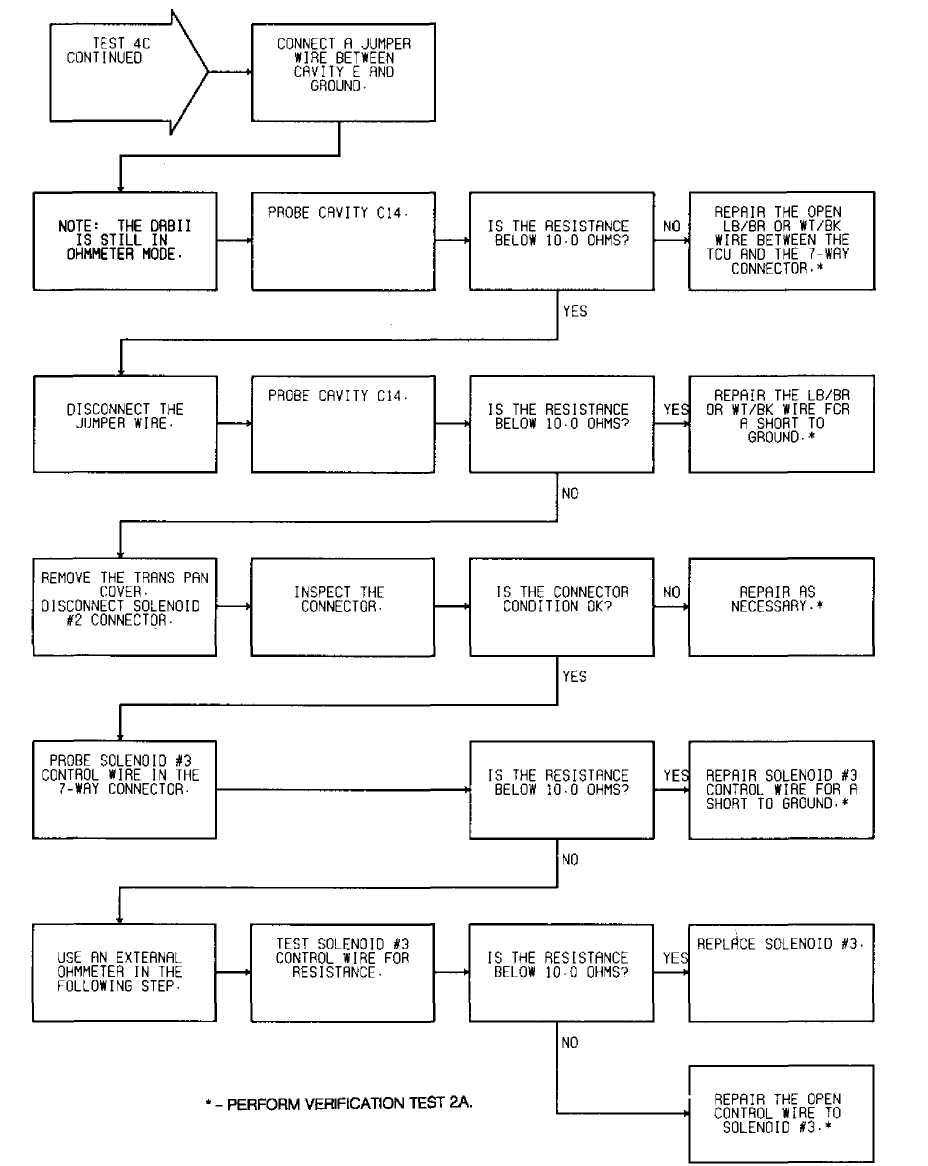

TEST 4C - CODE 700 - S3 SOLENOID CIRCUIT

Perform TEST 4A before proceeding.

* - PERFORM VERIFICATION TEST 2A.

* - PERFORM VERIFICATION TEST 2A.

ąŁ2ąÉ13615

Fig. 32: Test 4C - Code 700, Flow Chart (1 of 2)

92J13598

92J13598

Fig. 33: Test 4C - Code 700, Schematic (Cherokee)

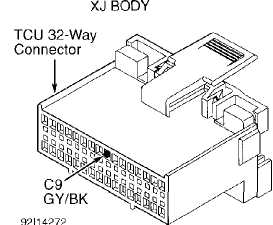

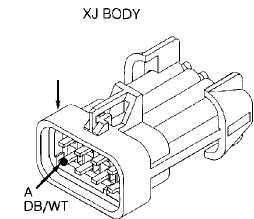

92B13616 XJ BODY

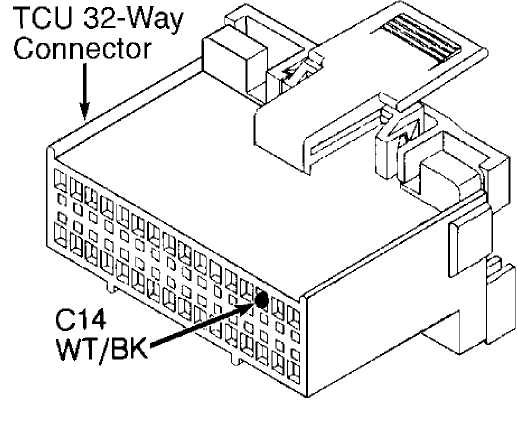

Fig. 34: Test 4C - TCU 32-Way Connector (Cavity 14, Cherokee)

Fig.

Fig.

92F13594

35: Test 4C - Code 700, Location of 7-Way Connector

NOTE: See TEST 4C (1 OF 2) for wiring diagram.

92D13618

Fig. 36: Test 4C - Code 700, Flow Chart (2 of 2)

92J13598

92J13598

Fig. 37: Test 4B - Code 700, Schematic (Cherokee)

Transmission

Transmission

Lt. Gray

7-Way Connector

XJ BODY

ąŁ2ąĢ13619

Fig. 38: Test 4C - 7-Way Connector Cavity "E" (Cherokee)

TCU 32-WAY CONNECTOR

C14 WT/BK

ZJ Body: LB/BR 92ą?3621

Fig. 39:

Test 4C - Code 700, TCU 32-Way Connector (Cavity 14)

Test 4C - Code 700, TCU 32-Way Connector (Cavity 14)

92ą?3605 Connector

Fig. 40: Test 4C - Code 700, Location of Solenoids

92J13622

|

CAV |

XJ |

ZJ |

|

E |

WT/BK |

LB/BR |

Fig. 41: Test 4C - Code 700, Solenoid No. 1 Wire (Cavity "E")

Transmission

Transmission

LI. Gray

7-Way Connector

Fig. 42: Test 4C - Code 700, Testing S3 Control Wire

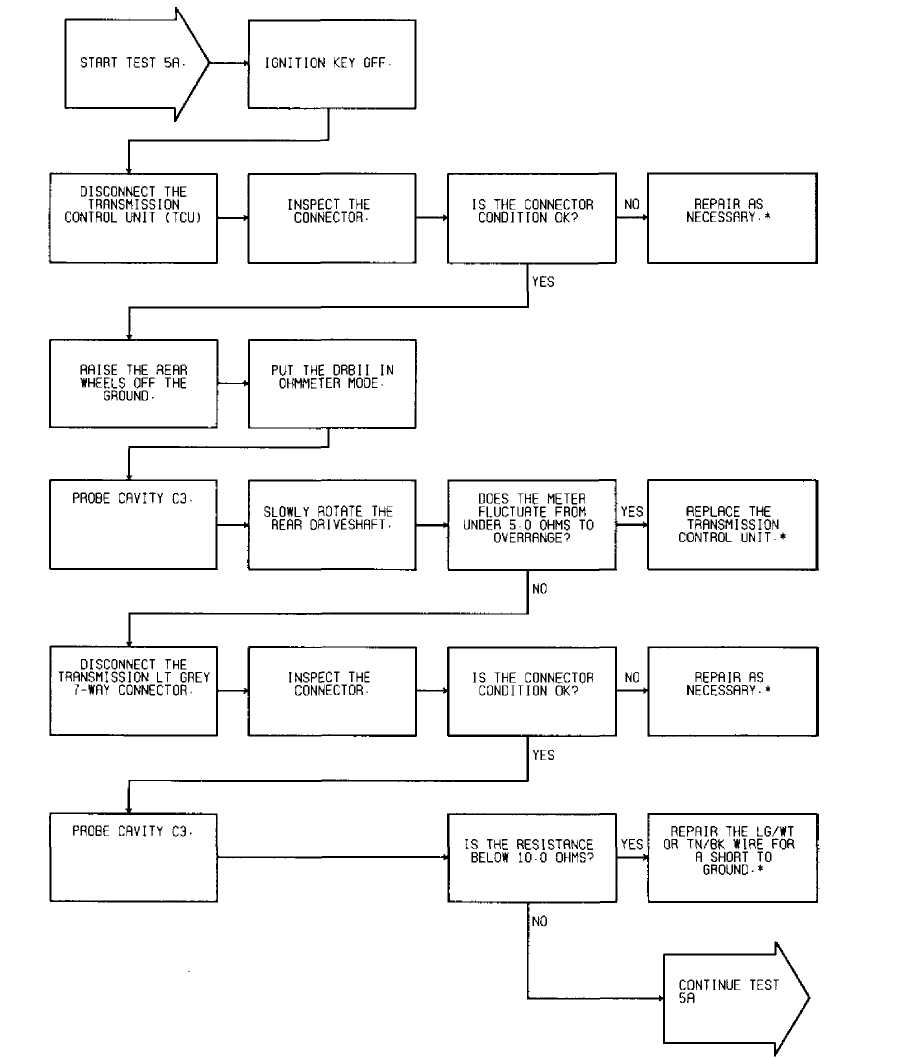

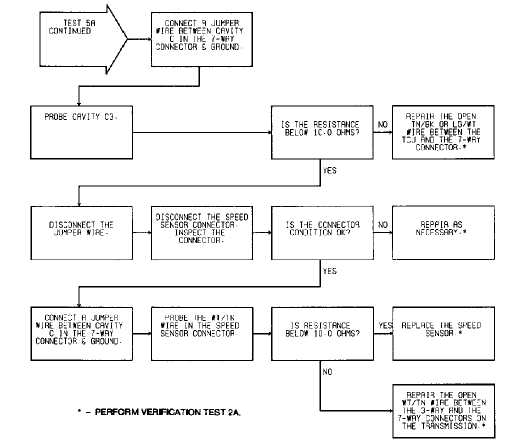

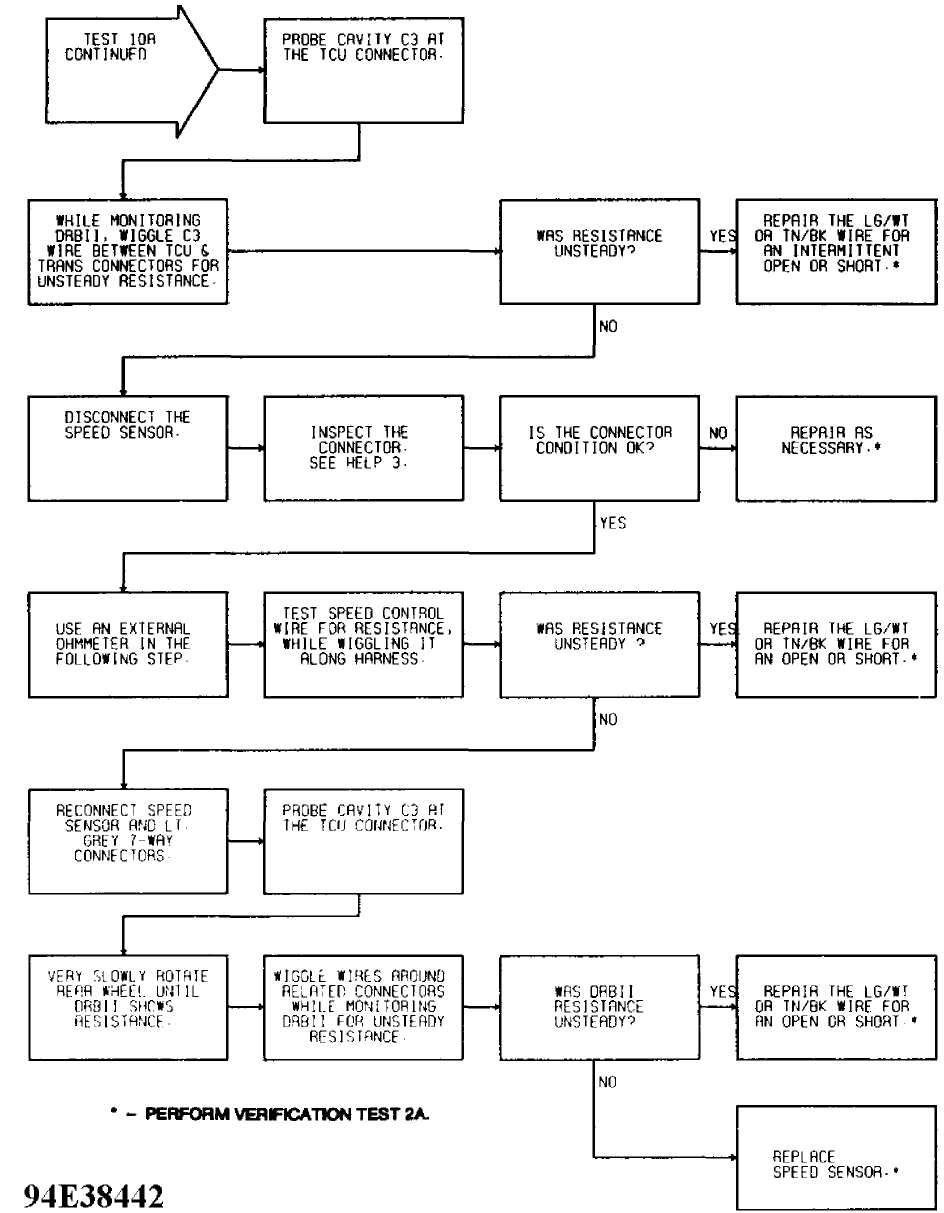

TEST 5A - CODE 702 - SPEED SENSOR CIRCUIT

NOTE: Perform TEST 1A - VERIFICATION OF COMPLAINT before proceeding.

Perform TEST 1A before proceeding.

" - PERFORM VERIFICATION TEST 2A. 94H38445

" - PERFORM VERIFICATION TEST 2A. 94H38445

Fig. 43: Test 5A - Code 702, Flow Chart (1 of 2)

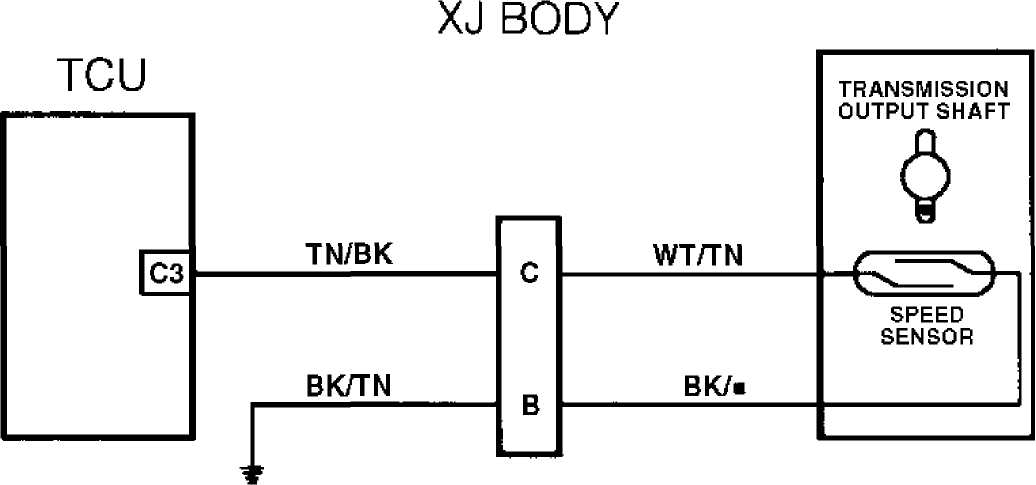

7-WAY

94D38433 CONNECTOR

Fig. 44: Test 5A - Code 702, Speed Sensor Schematic (Cherokee)

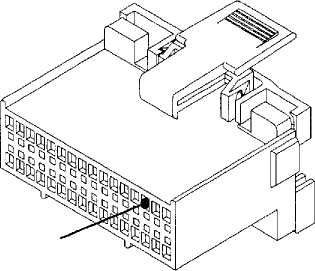

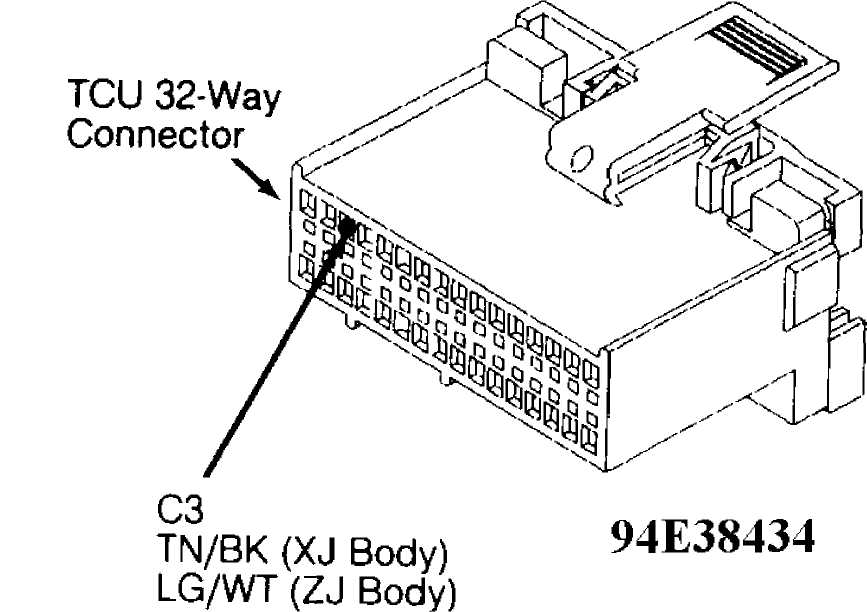

Fig. 45: Test 5A - Code 702, TCU 32-Way Connector (Cavity 3)

92F13594

92F13594

Fig. 46: Test 5A - Code 702, Location of 7-Way Connector

NOTE: See TEST 5A (1 OF 2) for wiring diagram.

94F3B435

Fig. 47: Test 5A - Code 702, Flow Chart (2 of 2)

7-WAY

94D38433 CONNECTOR

Fig. 48: Test 5A - Code 702, Speed Sensor Schematic (Cherokee)

Transmission

Transmission

Lt. Grey

7-Way Connector

Fig. 49: Test 5A - Transmission 7-Way Connector (Male Side)

Fig. 50: Test 5A - Code 702, TCU 32-Way Connector (Cavity 3)

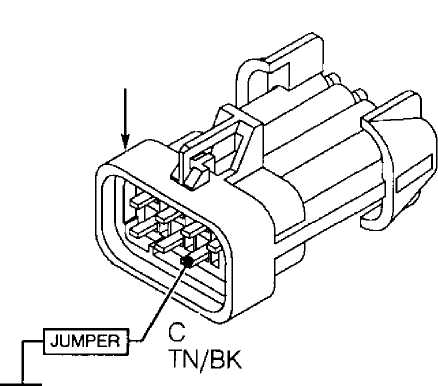

Fig. 51:

Fig. 51:

C3

TN/BK (XJ Body)

LG/WT (ZJ Body)

Test 5A - Code 702, TCU 32-Way Connector (Cavity 3)

92H14255

Fig. 52: Test 5A - Transmission 7-Way Connector (Female Side)

WT/TN

WT/TN

92114256

Fig. 53: Test 5A - Code 702, View of Speed Sensor Connector

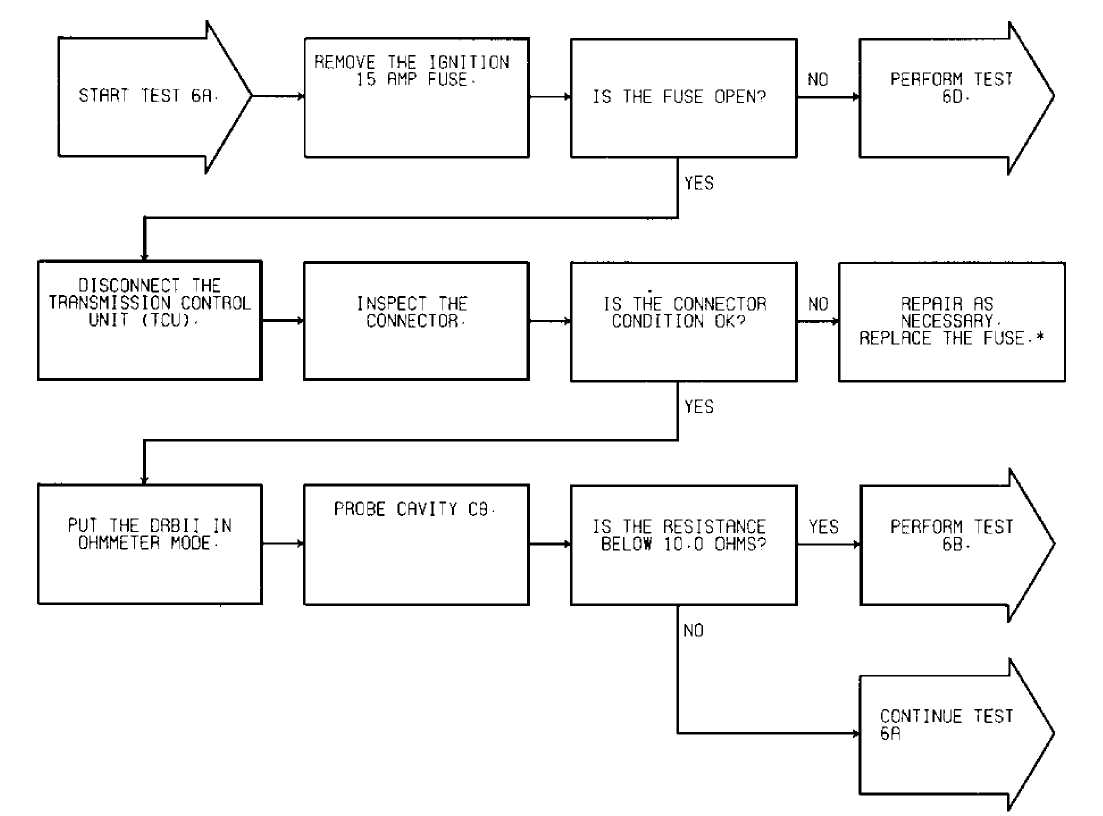

TEST 6A - CODE 703 - GEAR SELECT SWITCH CIRCUIT

Perform TEST 1A before proceeding.

92 ąø 4257 "-PERFORM VERIFICATION TEST 2A.

92 ąø 4257 "-PERFORM VERIFICATION TEST 2A.

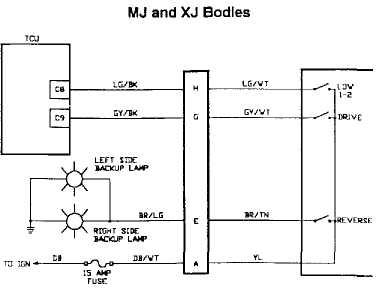

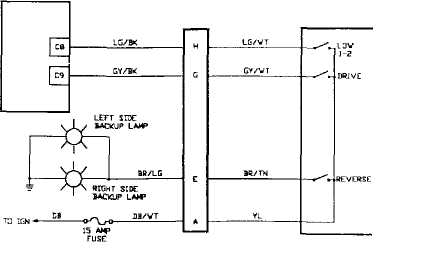

Fig. 54: Test 6A - Code 703, Flow Chart (1 of 2) MJ and XJ Bodies

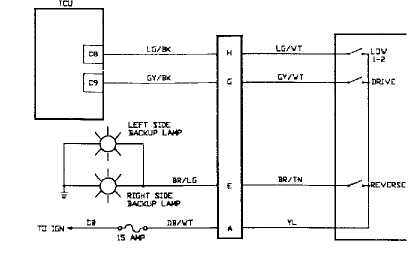

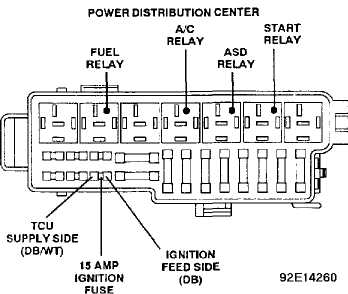

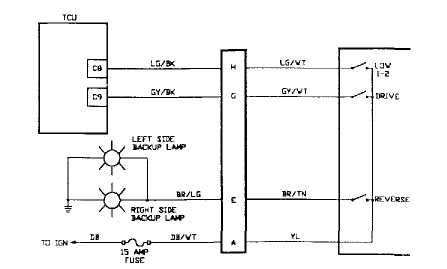

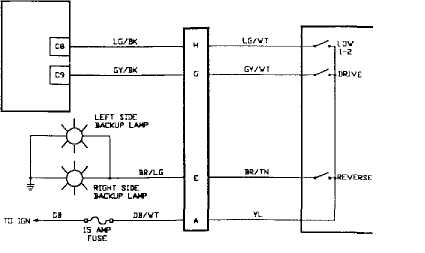

FUSE fl-U*Y GEAR SELECT

92ąö14258 ąĪą¤ą¢ąĪąóą¤!

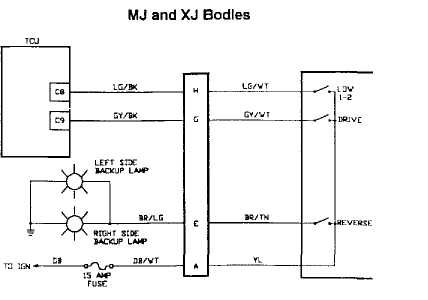

Fig. 55: Test 6A - Gear Select Switch Schematic (Cherokee)

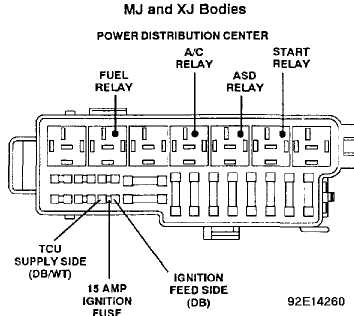

MJ and XJ Bodies

Fig. 56: Test 6A - Location of Gear Select Switch Fuse (Cherokee)

ZJ Body: I_G 92G14262

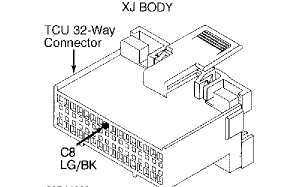

Fig. 57: Test 6A - TCU 32-Way Connector (Cavity 8)

92H14263

Fig. 58: Test 6A - Code 703, Flow Chart (2 of 2)

B-U┬╗V GEAR SELLCT

92 A14258 ą┐ą╗ą╝ą│ą┐ąĖ

Fig. 59: Test 6A - Gear Select Switch Schematic (Cherokee)

ZJ Body: DQ

Fig. 60: Test 6A

- Code 703, TCU 32-Way Connector (Cavity 9)

Transmission

Transmission

Lt. Gray

92F13594

7-Way Connector

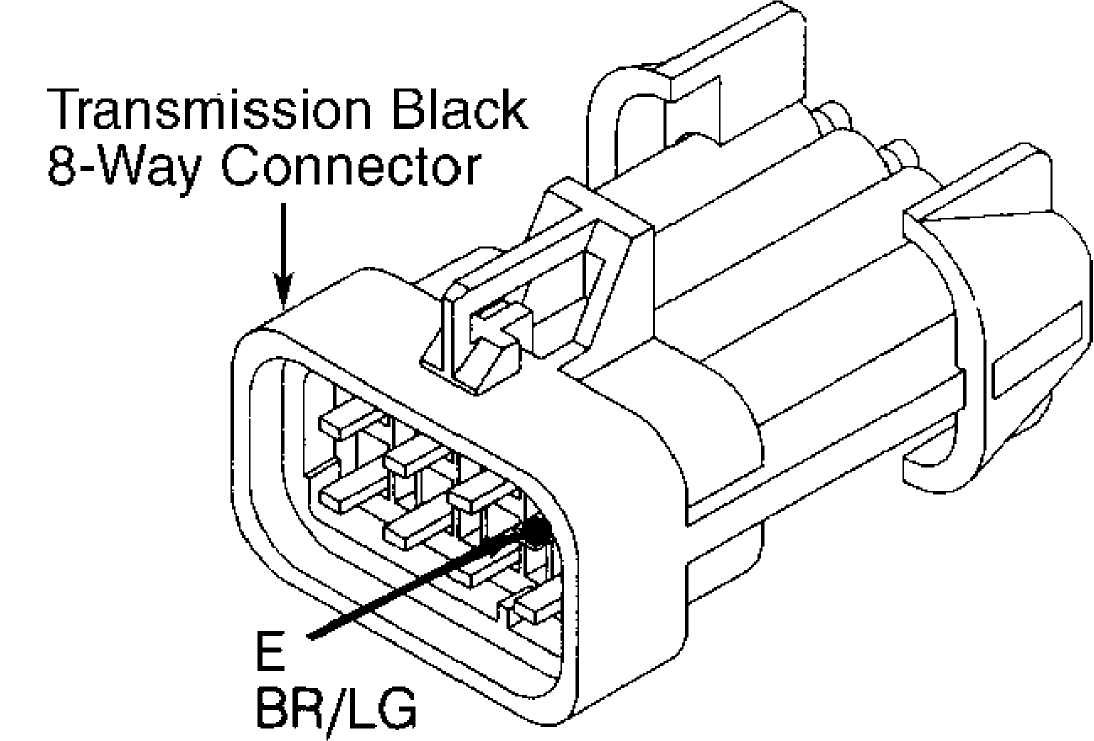

Fig. 61: Test 6A - Code 703, Location of Gear Select Switch

92J14265

92J14265

Fig. 62: Test 6A - Code 703,

XJ BODY

8-Way Black Connector Cavity "E"

ąŁ2ąÉ14266

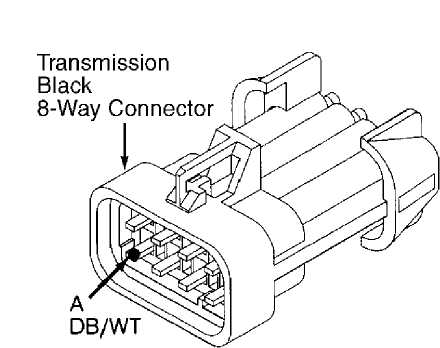

Fig. 63: Test 6A - 8-Way Black Connector Cavity "A" (Cherokee)

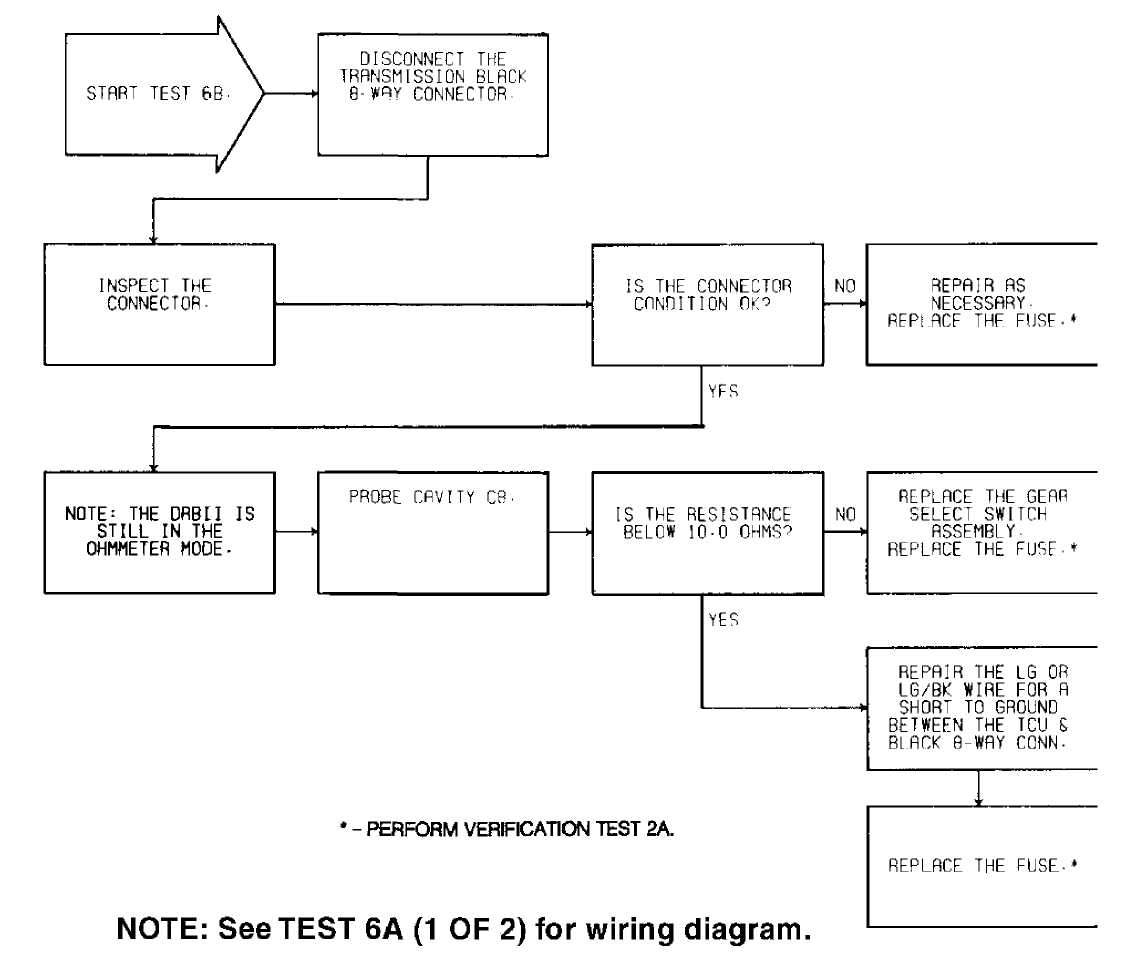

TEST 6B - CODE 703 - GEAR SELECT SWITCH CIRCUIT

NOTE: Perform TEST 6A - CODE 703 - GEAR SELECT SWITCH CIRCUIT

before proceeding.

Perform TEST 6A before proceeding.

ąŁ2ąĪ14268

Fig. 64: Test 6B - Code 703, Flow Chart

MJ and XJ Bodies

B-U┬╗V GEAR SELLCT

92 A14258 ą┐ą╗ą╝ą│ą┐ąĖ

Fig. 65: Test 6B - Gear Select Switch Schematic (Cherokee)

92F13594

92F13594

Fig. 66: Test 6B - Code 703, Location of Gear Select Switch

Fig. 67: Test 6B - TCU 32-Way Connector (Cavity 8, Cherokee)

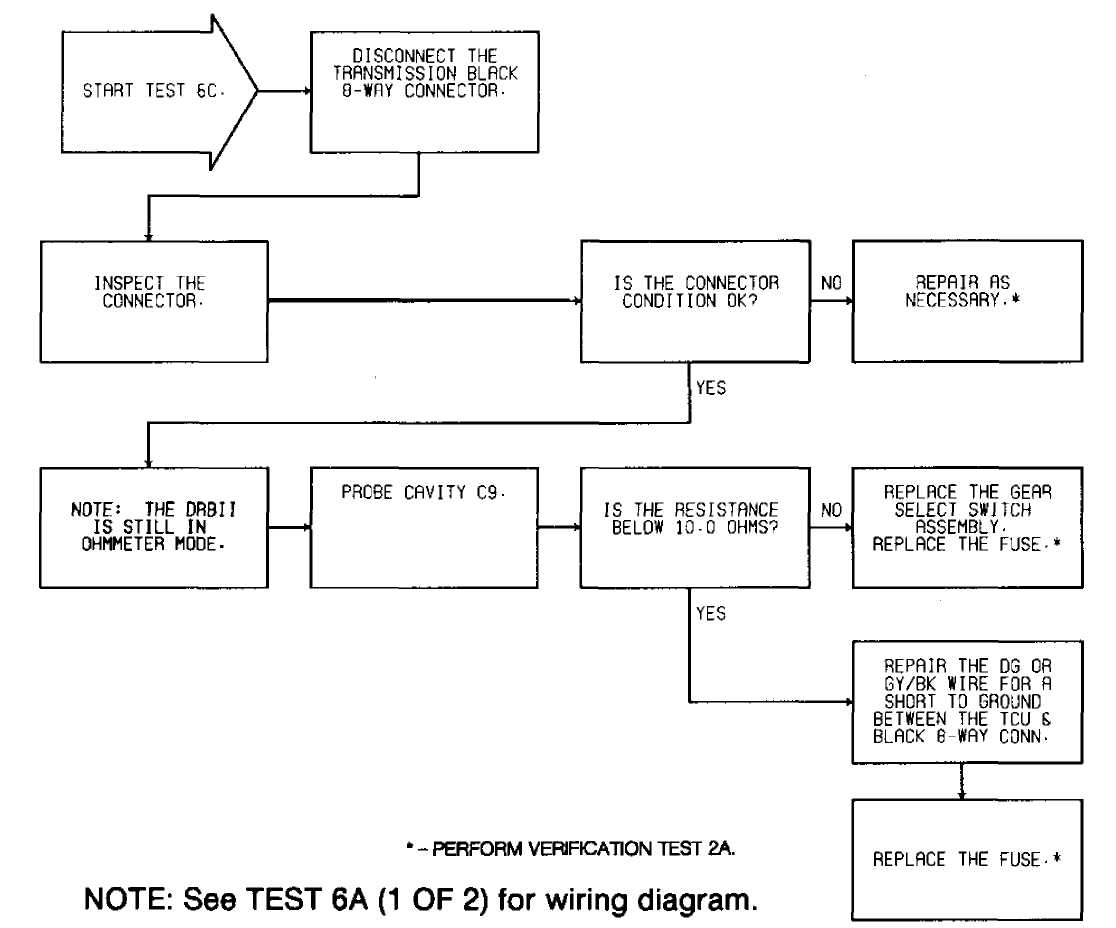

TEST 6C - CODE 703 - GEAR SELECT SWITCH CIRCUIT

NOTE: Perform TEST 6A - CODE 703 - GEAR SELECT SWITCH CIRCUIT before proceeding.

Perform TEST 6A before proceeding.

ąŁ2ąØ14271

Fig. 68: Test 6C - Code 703, Flow Chart

MJ and XJ Bodies

B-U┬╗V GEAR SELLCT

92 A14258 ą┐ą╗ą╝ą│ą┐ąĖ

Fig. 69: Test 6C - Gear Select Switch Schematic (Cherokee)

92F13594

Fig. 70: Test 6C - Code 703, Location of Gear Select Switch

Fig. 71: Test 6C - TCU 32-Way Connector (Cavity 9, Cherokee)

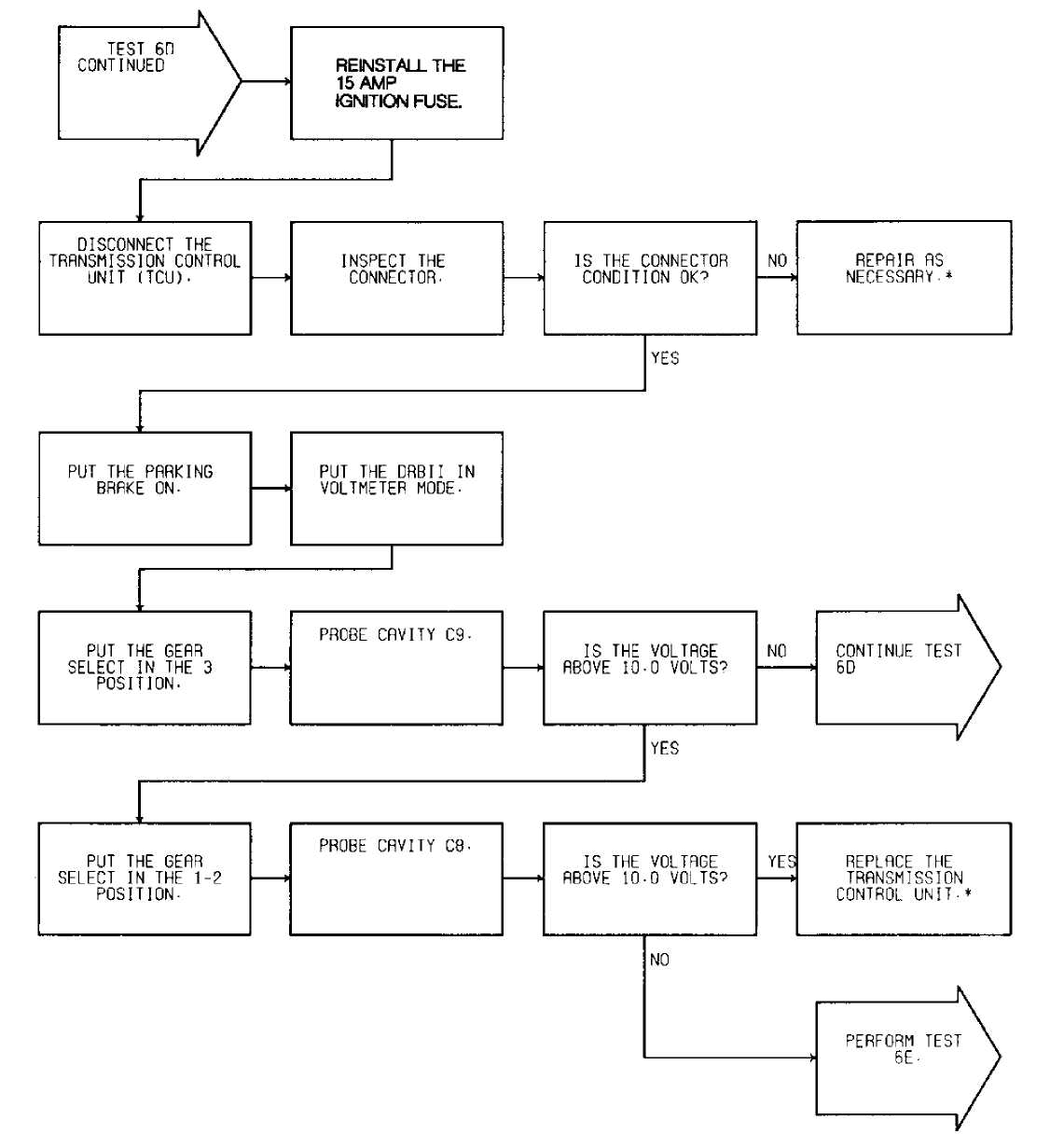

TEST 6D - CODE 703 - GEAR SELECT SWITCH CIRCUIT

NOTE:

Perform TEST 6A - CODE 703 - GEAR SELECT SWITCH CIRCUIT before proceeding.

Fig. 72: Test 6D - Code 703, Flow Chart (1 of 3) MJ and XJ Bodies

B-W┬╗y GEAR SELLCT

92 A14258 ą┐ą╗ą╝ą│čéą░

Fig. 73: Test 6D - Gear Select Switch Schematic (Cherokee)

Fig. 74: Test 6D - Location of Gear Select Switch Fuse (Cherokee)

ąŁ2ąÆ14275

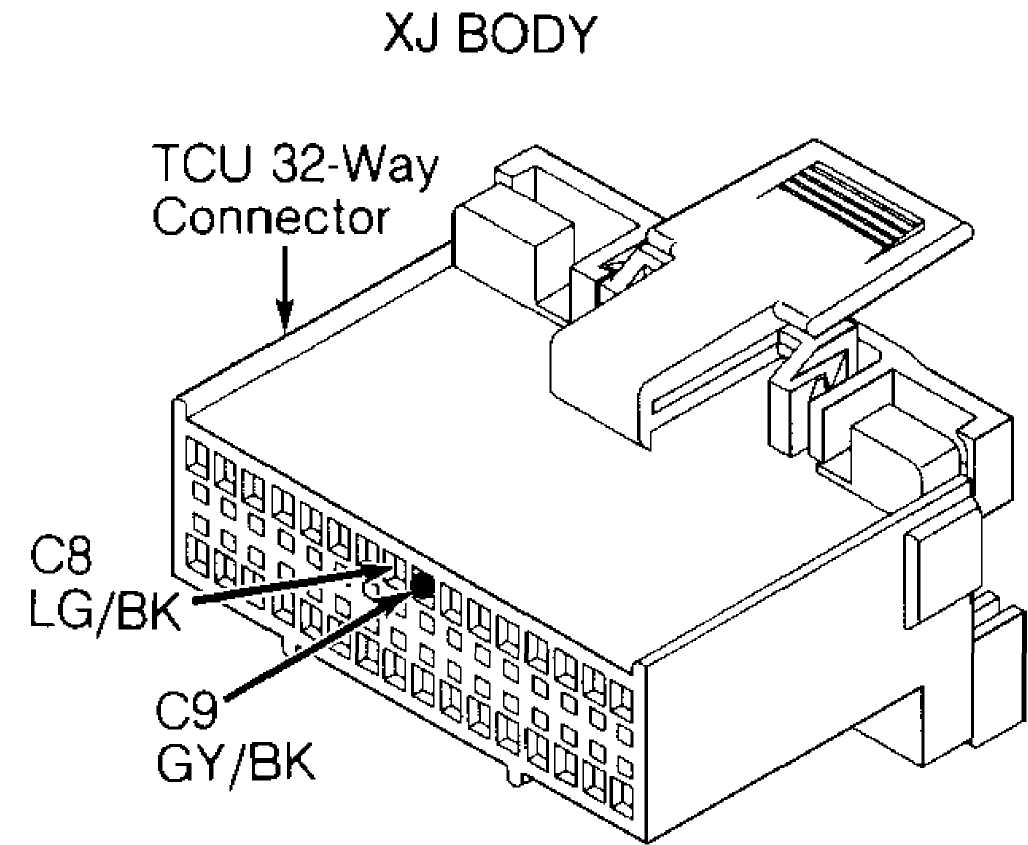

Fig. 75: Test 6D - TCU 32-Way Connector (Cavities 8 & 9, Cherokee)

92D14277 *-PERFORM VERIFfCATlON TEST 2A.

Fig. 76: Test 6D - Code 703, Flow Chart (2 of 3)

92 A14258 ą┐ą╗ą╝ą│ą┐ąĖ

Fig. 77: Test 6D - Gear Select Switch Schematic (Cherokee)

92B14275

Fig. 78: Test 6D - TCU 32-Way Connector (Cavities 8 & 9, Cherokee)

ąŁ2ąĢ14278

Fig. 79: Test 6D - Code 703, Flow Chart (3 of 3)

B-U┬╗V GEAR SELLCT

92 A14258 ą┐ą╗ą╝ą│ą┐ąĖ

Fig. 80: Test 6D - Gear Select Switch Schematic (Cherokee)

92F13594

Fig. 81: Test 6D - Code 703, Location of Gear Select Switch

ąŁ2ąÉ14266

Fig. 82: Test 6D - 8-Way Black Connector Cavity "A" (Cherokee)

XJ BODY

92F14279

Fig. 83: Test 6D - 8-Way Black Connector Cavity "G" (Cherokee)

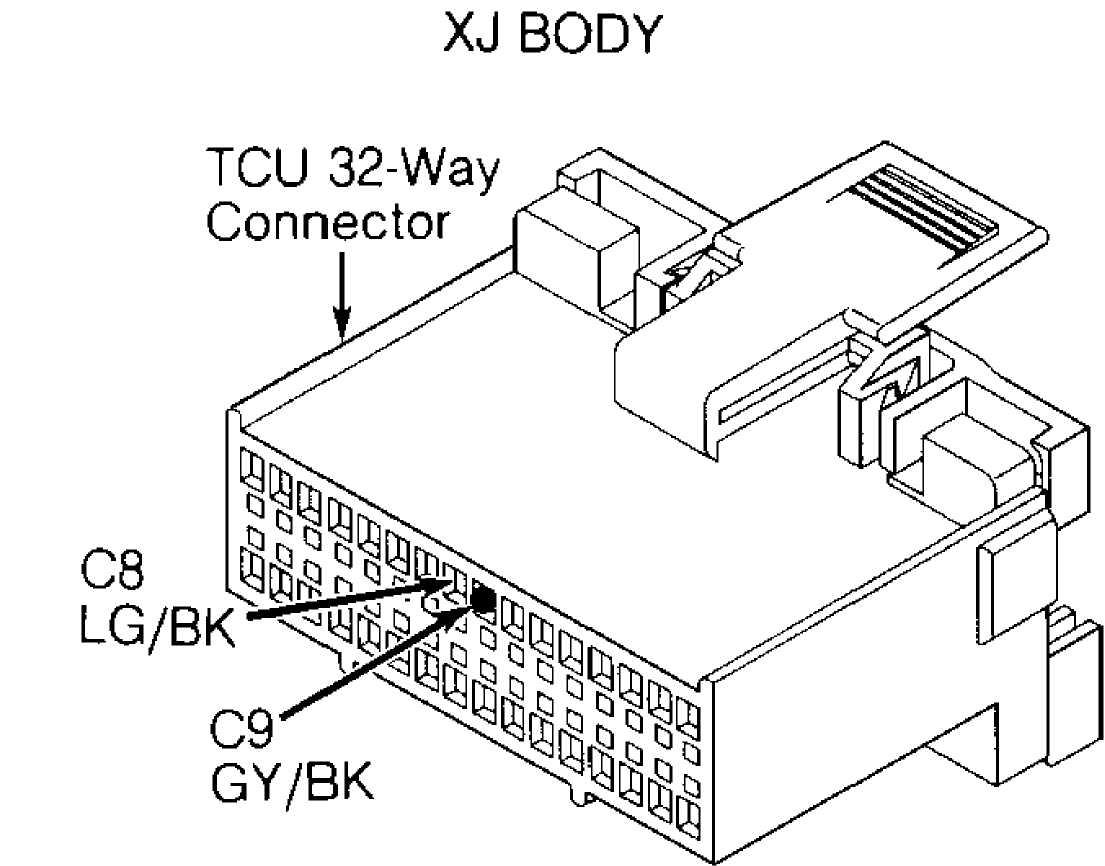

ZJ Body: DG 92114264

Fig. 84: Test 6D - Code 703, TCU 32-Way Connector (Cavity 9)

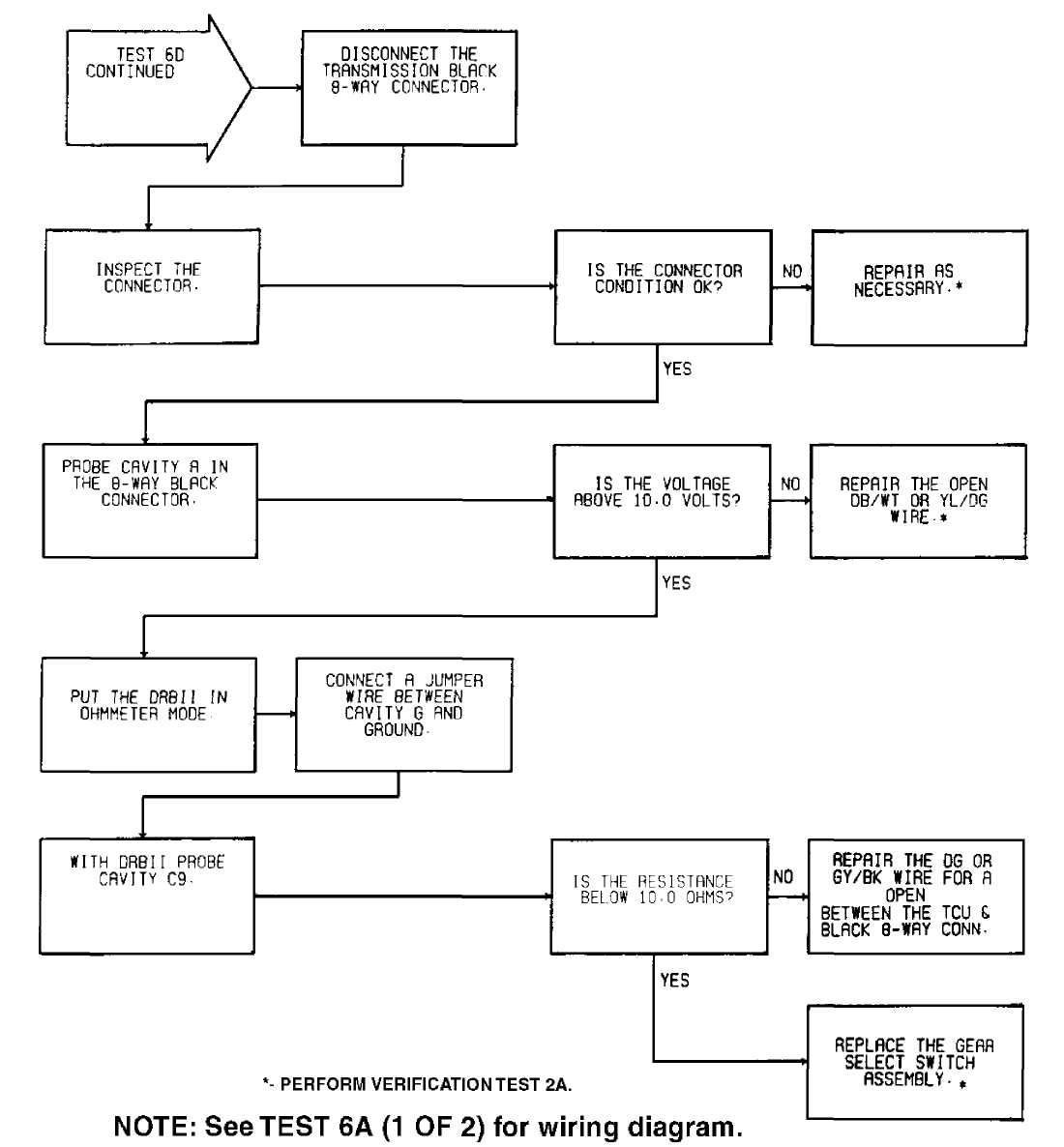

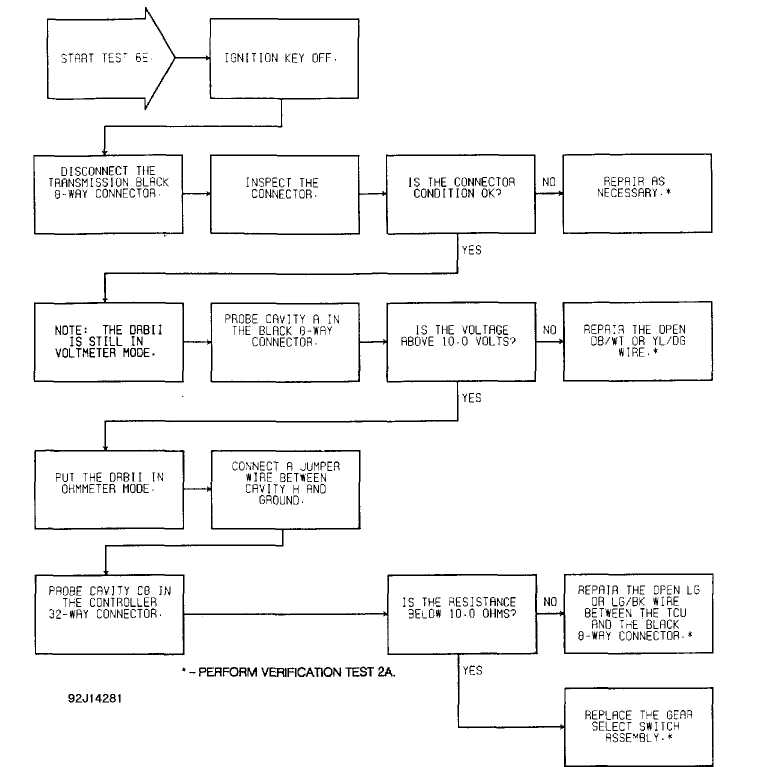

TEST 6E - CODE 703 - GEAR SELECT SWITCH CIRCUIT

NOTE: Perform TEST 6D - CODE 703 - GEAR SELECT SWITCH CIRCUIT before proceeding.

Fig. 85: Test 6E - Code 703, Flow Chart

92 A14258 ą┐ą╗ą╝ą│ą┐ąĖ

Fig. 86: Test 6E - Gear Select Switch Schematic (Cherokee)

92F13594

Transmission

Black

8-Way Connector

Fig. 87: Test 6E - Code 703, Location of Gear Select Switch

ąŁ2ąÉ14266

Fig. 88: Test 6E - 8-Way Black Connector Cavity "A" (Cherokee)

Fig.

9: Test 6E - 8-Way Black Connector Cavity "H" (Cherokee)

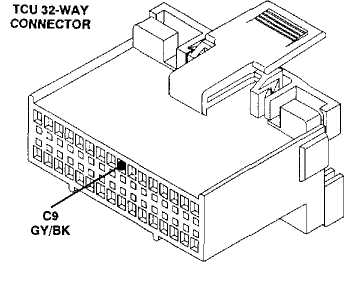

TCU 32-WAY CONNECTOR

ZJ Body: LG 92G14262

ZJ Body: LG 92G14262

Fig. 90: Test 6E - TCU 32-Way Connector (Cavity

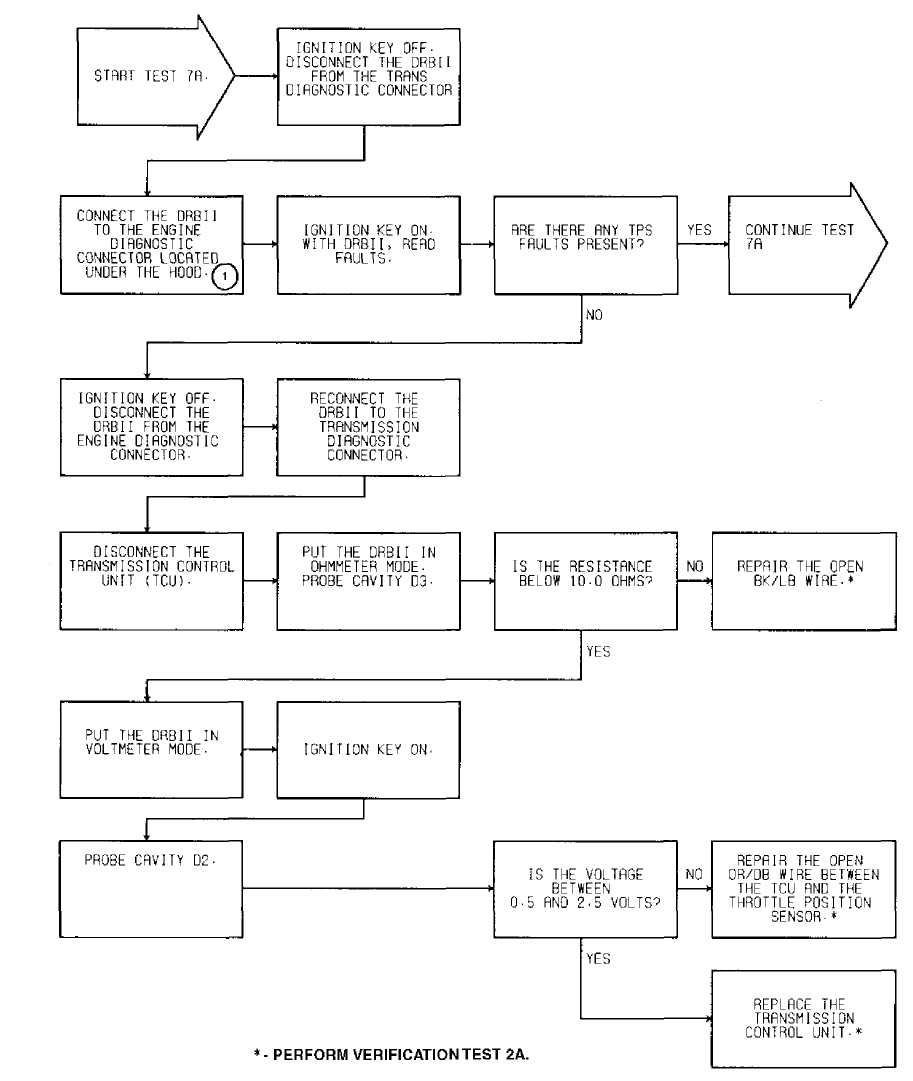

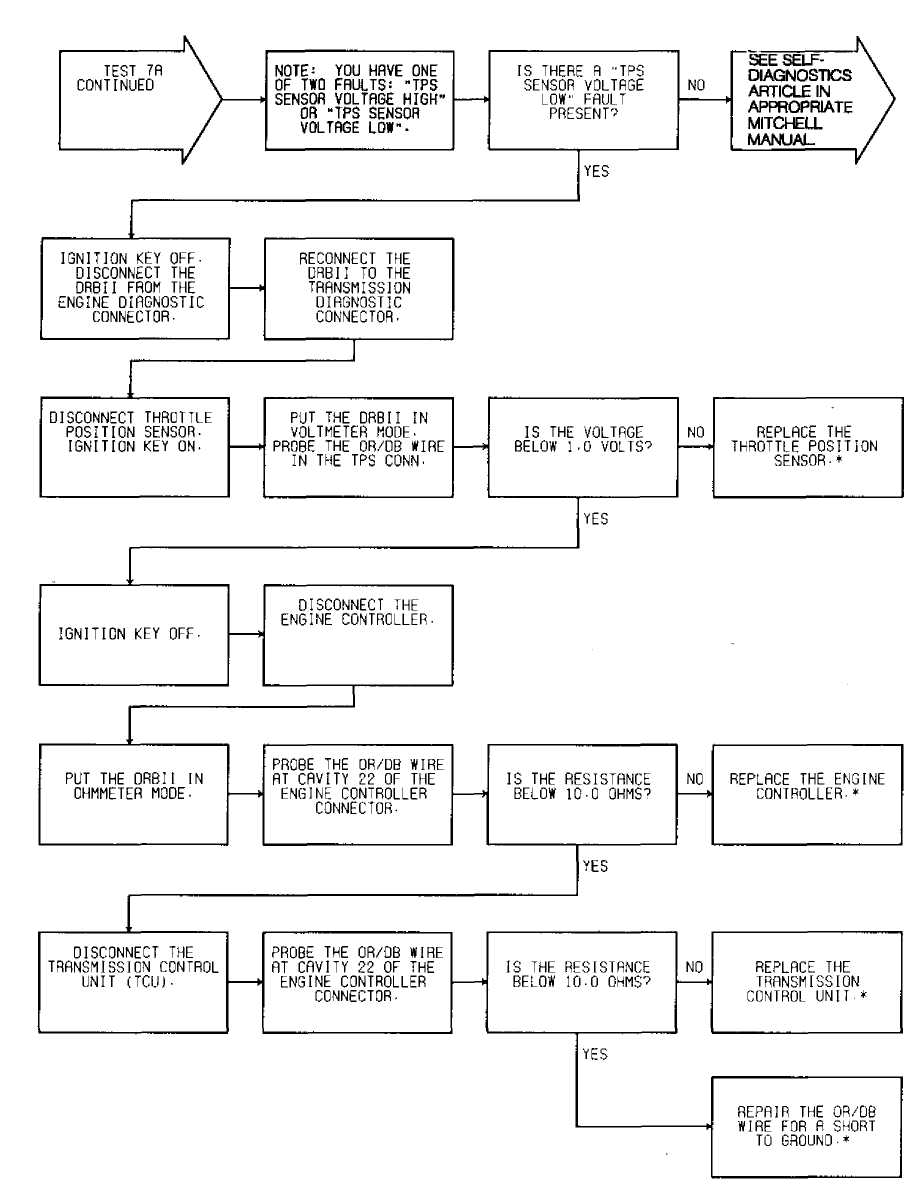

TEST 7A - CODE 705 - TPS CIRCUIT

NOTE: Perform TEST 1A - VERIFICATION OF COMPLAINT before proceeding.

NOTE: On Cherokee, engine diagnostic connector is located at left side of engine compartment, near engine controller. Engine diagnostic connector is a 6-terminal connector.

Perform TEST 6D before proceeding.

┬® - On XJ models, engine diagnostic connector is located at left side of engine compartment, near engine controller.

94138438

Fig. 91: Test 7A - Code 705, Flow Chart (1 of 2)

Fig. 92: Test 7A - Code 705, Schematic

92E142S6

92E142S6

Fig. 93: Test 7A - TCU 32-Way Connector (Cavities D2 & D3)

ŌĆó - PERFORM VERIFICATION TEST 2A.

ŌĆó - PERFORM VERIFICATION TEST 2A.

NOTE: See TEST 7A {1 OF 2) for wiring diagram.

92F14287

Fig. 94: Test 7A - Code 705, Flow Chart (2 of 2)

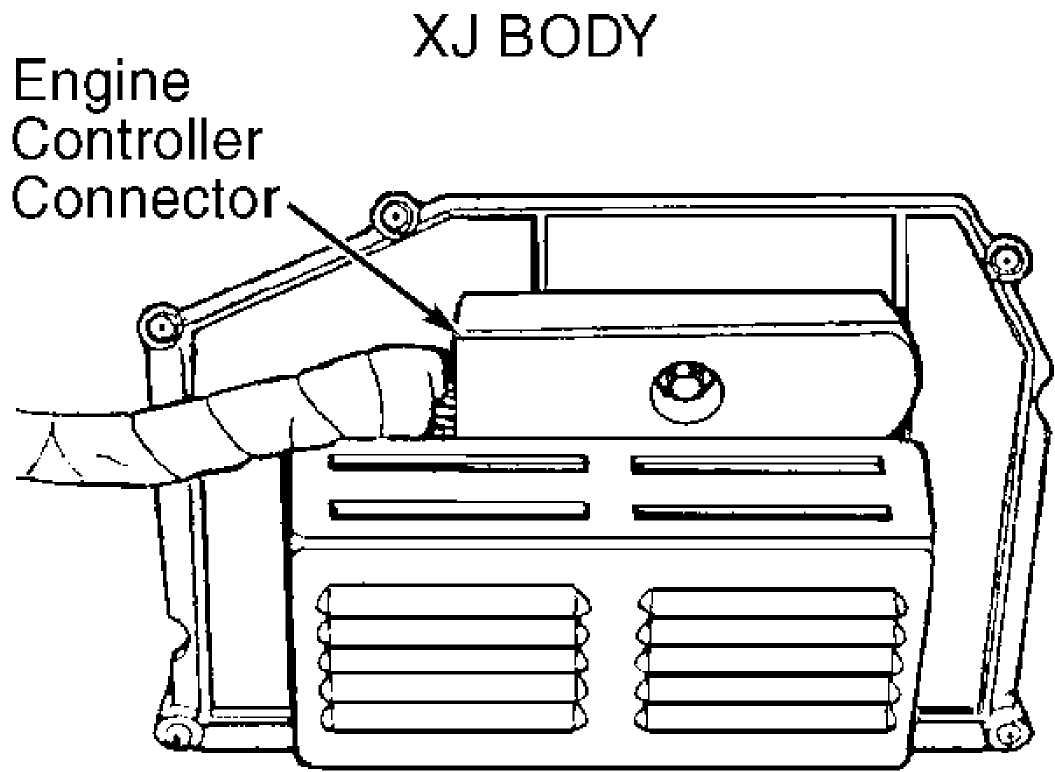

ENGINE CONTROLLER

Fig. 95: Test 7A - Code 705, Schematic

92G14288

Fig. 96: Test 7A - Location of Throttle Position Sensor (TPS)

92H14289

Fig. 97: Test 7A - Code 705, View of TPS Connector

92A14290

Fig. 98: Test 7A - Location of Engine Control Connector (Cherokee)

92C14292

Fig. 99: Test 7A - View of Engine Control Connector (Cavity 22)

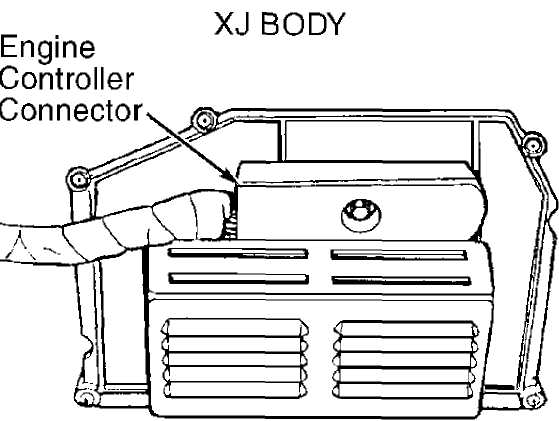

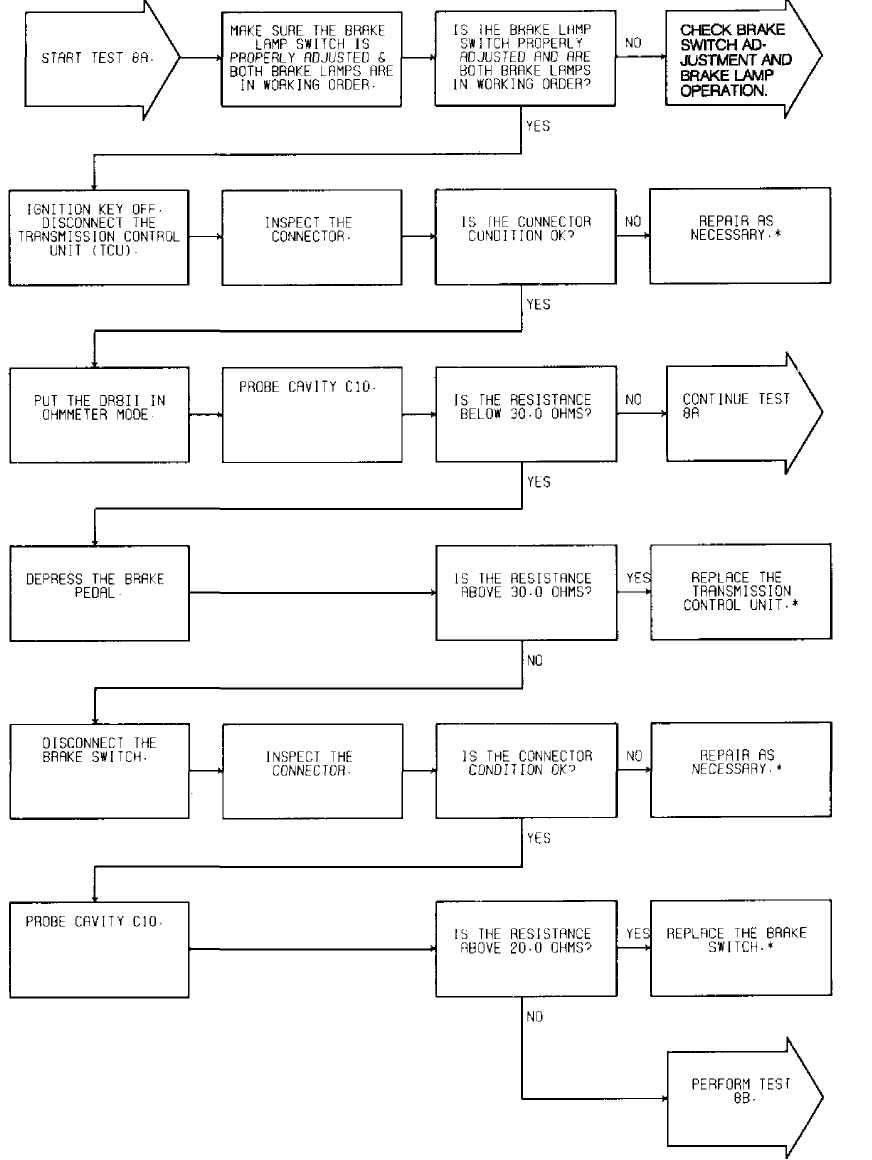

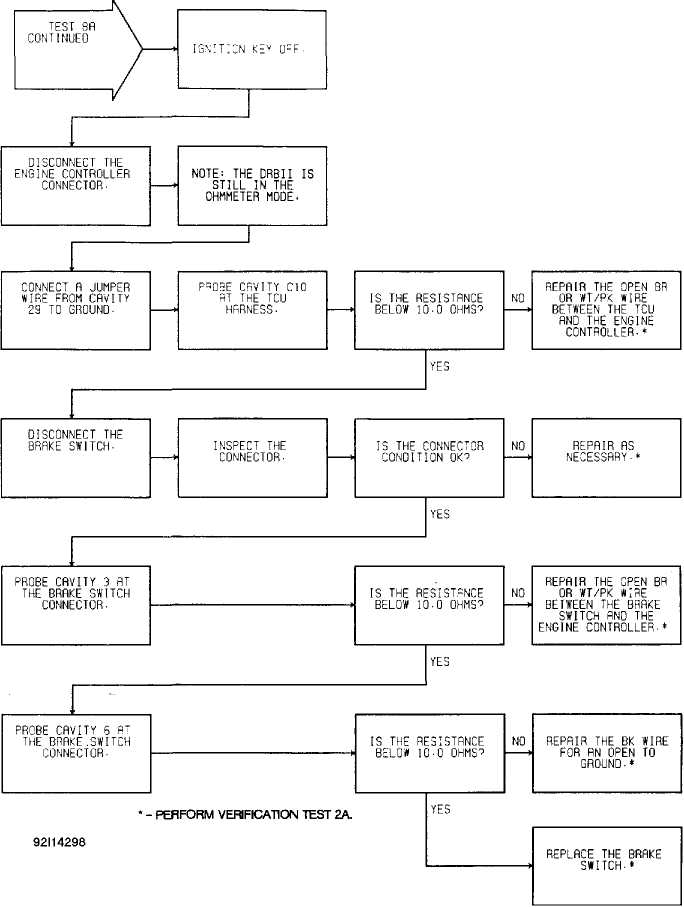

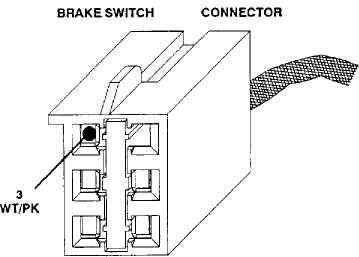

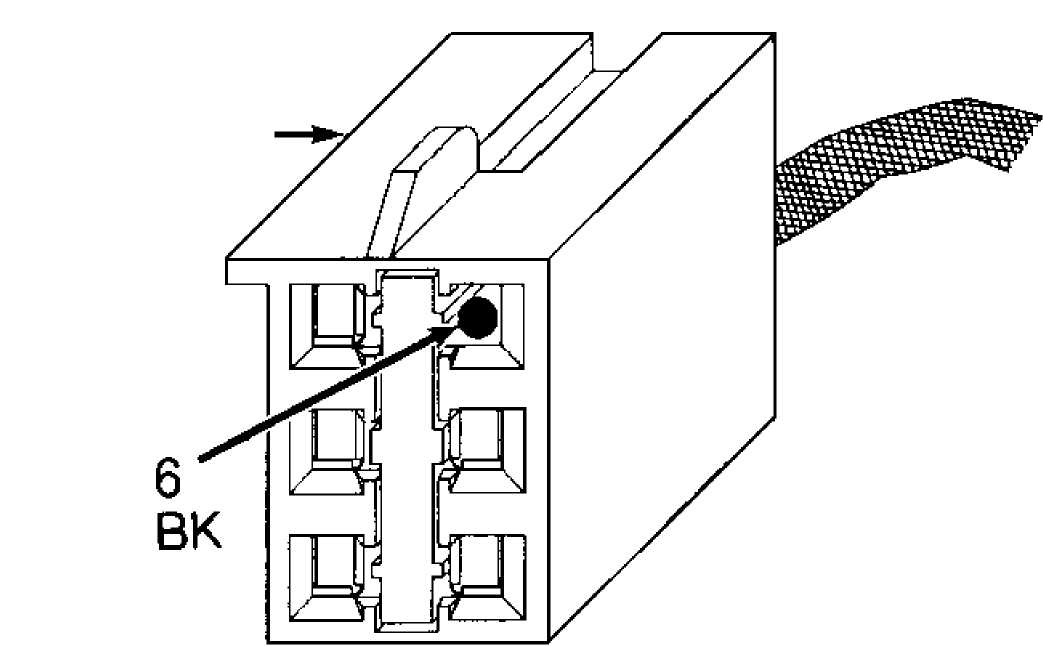

TEST 8A - CODE 706 - BRAKE SWITCH CIRCUIT

NOTE: Perform TEST 1A - VERIFICATION OF COMPLAINT before proceeding.

Perform TEST 1A before proceeding.

92D14293 *" PERF0RM VERIFICATION TEST 2A.

Fig. 100: Test 8A - Code 706, Flow Chart

92E14294

Fig. 101: Test 8A - Code 706, Schematic (Cherokee)

Fig. 101: Test 8A - Code 706, Schematic (Cherokee)

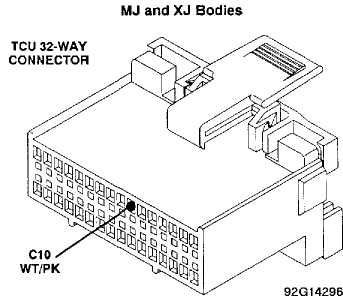

Fig. 102: Test 8A - TCU 32-Way Connector (Cavity 10, Cherokee)

ąŁ2ąĪ13583

ąŁ2ąĪ13583

Fig. 103: Test 8A

- Location of Brake Switch Connector

Fig. 104: Test 8A - Code 706, Flow Chart

XJ BODY TCU

XJ BODY TCU

92E14294

Fig. 105: Test 8A

Engine Controller

Code 706, Schematic (Cherokee)

92J14299

Fig. 106: Test 8A - View of Engine Controller Connector (Cavity 29)

92G14296

Fig. 107: Test 8A - TCU 32-Way Connector (Cavity 10, Cherokee)

92C13583

Fig. 108: Test 8A - Location of Brake Switch Connector

ZJBody: BR

Fig. 109: Test 8A - View of Brake Switch Connector (Cavity 3)

Brake

Switch

Connector

92D14301

Fig. 110: Test 8A - View of Brake Switch Connector (Cavity 6)

TEST 8B - CODE 706 - BRAKE SWITCH CIRCUIT

NOTE: Perform TEST 8A - CODE 706 - BRAKE SWITCH CIRCUIT before proceeding.

Perform TEST 8A before proceeding.

ąŁ2ąĢ14302

Fig. 111: Test 8B - Code 706, Flow Chart

Fig. 112: Test 8B -

- Code 706, Schematic (Cherokee)

92A14290

Fig. 113: Test 7A - Location of Engine Control Connector (Cherokee)

92G14296

Fig. 114: Test 8B - TCU 32-Way Connector (Cavity 10, Cherokee)

TEST 9A - WRONG TCU

NOTE: Perform TEST 1A - VERIFICATION OF COMPLAINT before proceeding.

NOTE: The AW-4 is used only on 4.0L. In earlier years, it was

used with 2.5.L

The DRB-II has determined that the wrong Transmission Control Unit (TCU) has been installed in the vehicle. There are two transmission control units available for the Jeep AW4 transmission. One is for the 4-cylinder 2.5L engine and the other is for the 6-cylinder 4.0L engine.

using the DRB-II, read MODULE INFO. See HELP 1 for

assistance.

Determine what vehicle should be in the vehicle.

2.5L Engine: TCU 02 (Used in earlier years only)

4.0L Engine: TCU 01 (1993-94)

3) If the wrong transmission control unit is installed, the

vehicle shift points will be slightly different (the 2.5L engine TCU

has higher shift points).

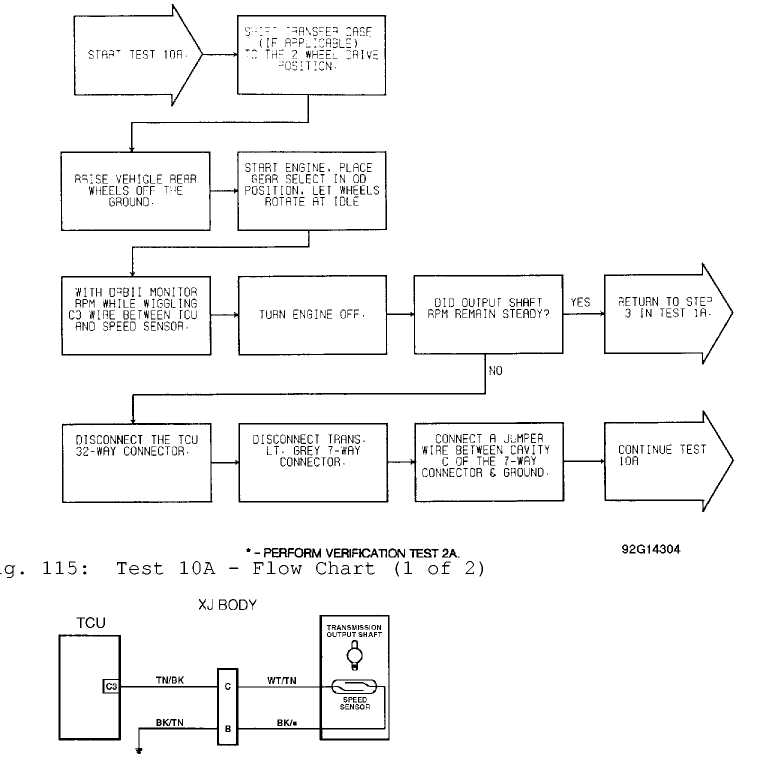

TEST 10A - TESTING FOR INTERMITTENT SPEED SENSOR

NOTE: Perform TEST 1A - VERIFICATION OF COMPLAINT before proceeding.

7-WAY

94ąĪąŚą»4ąöą¤ CONNECTOR

Fig. 116: Test 10A - Schematic (Cherokee)

92F13594

Fig. 117: Test 10A - Location of Transmission Connectors

XJ BODY

Transmission

Lt. Gray

7-Way Connector

94D38441 Fig. 118: Test 10A - View of 7-Way Connector (Cherokee)

Fig. 119: Test 10A - Flow Chart (2 of 2)

94C38440

94C38440

Fig. 120: Test 10A - Schematic (Cherokee)

7-WAY CONNECTOR

Fig. 121: Test 10A - TCU 32-Way Connector (Cavity 3)

92G14254

92G14254

Fig. 122: Test 10A - Location of Speed Sensor Connector

XJ BODY

TCU 32-Way Connector

Speed Sensor Connector

Speed Sensor Connector

94G38444

Fig. 123: Test 10A - Testing Speed Sensor (Cherokee)

WIRING DIAGRAMS

Fig. 124: Transmission Wiring Diagram (Cherokee)

Courtesy of Chrysler Corp.

REMOVAL & INSTALLATION

BRAKE SWITCH R & I

Removal

Remove lower steering column cover or trim panels for access to brake switch (if necessary). Disconnect brake switch electrical connector. Thread brake switch from retainer and remove.

Fig.

CHEROKEE

CAV... CIRCUIT FUNCTION

C1-C2 Not Used

C3 505 TN/BK Trans Speed Sensor

C4 137 YL/BK Auto Trans Diagnostic

C5-C7 Not Used

C8 506 LG/BK Low (1-2) Input

C9 507 GY/BK Drive (3) Input

C10 K29 WT/PK Brake Input

C11 Not Used

C12-C13 Not Used

C14 508 WT/BK S3 Solenoid

(Converter Lockup)

C15 509 VT/WT S2 Solenoid

C16 510DB/WT S1 Solenoid

D1 Not Used

D2 K22 OR/DB Throttle Position Sensor

D3 K4BK/LB TPS Signal Ground

D4-D6 Not Used

D7 Z12B^N Power Ground

D8-D13 Not Used

D14 A14RD Battery

D15 Not Used

D16 T17 YL Ignition (Run/On)

125: TCM Connector Terminals I.D., Circuits

GRAND.CHEROKEE

CAV... CIRCUIT FUNCTION

C1-C2 Not Used

C3 T14 LG/WT Trans Speed Sensor

C4 D82 BK/YL Auto Trans Diagnostic

C5-C7 Not Used

C8 T25 LG Low (1-2) Input

C9 T50 DG Drive (3) Input

C10 .... L53 BR Brake Input

C11-C13 Not Used

C14 .... T20 LB/BR S3 Solenoid

(Converter Lockup)

C15 .... T59 PK S2 Solenoid

C16 .... T60 BR/YL S1 Solenoid

D1 Not Used

D2 K22 OR/DB Throttle Position Sensor

D3 K4 BK/LB TPS Signal Ground

D4-D6 Not Used

D7 21 BK Power Ground

D8-D13 ,. Not Used

D14 .... A14 RD/WT Battery

D15 Not Used

D16 .... F86 LB/RD Ignition (Run/On)

& Functions

Installation

Install brake switch in retainer. Reconnect brake switch

electrical connector.

To check brake switch adjustment, slightly depress brake

pedal and note operation of brake switch plunger. Brake switch plunger

should fully extend when brake pedal free play is taken up and brake

application begins.

Clearance between brake switch plunger and brake pedal

should be approximately 1/8". If clearance is not within

specification, pull brake pedal rearward as far as possible.

Brake pedal should contact brake switch plunger, pushing

brake switch backward in retainer to provide proper adjustment. Ensure

brake lights operate.

Recheck clearance between brake switch plunger and brake

pedal with brake pedal depressed and free play taken up. Reinstall

lower steering column cover or trim panels.

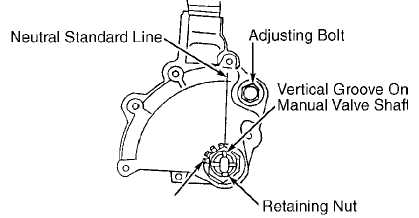

NEUTRAL SAFETY SWITCH R & I

NOTE: Neutral safety switch may be referred to as park/neutral or

gear select switch.

Removal

Apply parking brake. Raise and support vehicle. Disconnect

electrical connector at neutral safety switch. Pry lock washer tabs

away from retaining nut. See Fig. 126.

Remove retaining nut, lock washer and adjusting bolt. See

Fig. 126. Remove neutral safety switch from manual valve shaft.

Installation

Disconnect shift control rod from transmission shift

lever. Rotate transmission shift lever fully rearward and then forward

2 detents to Neutral position.

Install neutral safety switch on manual valve shaft.

Install adjusting bolt but DO NOT tighten at this time.

Install lock washer and retaining nut. Tighten retaining

nut to specification. See TORQUE SPECIFICATIONS. DO NOT bend over lock

washer tabs at this time.

Ensure transmission is still in Neutral. Rotate neutral

safety switch and align neutral standard line with vertical groove on

manual valve shaft. See Fig. 126.

Tighten adjusting bolt to specification. See

TORQUE SPECIFICATIONS at end of article. Bend lock washer tabs over. Reconnect shift control rod and electrical connector. Ensure vehicle starts in Park and Neutral only.

Lock Washer TabsÆ

92G13454

Fig. 126: Installing Neutral Safety Switch Courtesy of Chrysler Corp.

SPEED SENSOR R & I

Removal & Installation

Disconnect electrical connector at speed sensor located on

adapter housing or extension housing. Remove bolt and speed sensor.

Remove "O" ring from speed sensor.

To install, reverse removal procedure using NEW "O" ring.

Tighten bolt to specification. See TORQUE SPECIFICATIONS.

THROTTLE POSITION SENSOR (TPS) R & I

Removal & Installation

1) Note location of TPS electrical connector. See Fig. 127. Disconnect electrical connector. Remove screws and TPS.

Fig. 127: Identifying TPS Electrical Connector Courtesy of Chrysler Corp.

2) To install, reverse removal procedure. Ensure throttle shaft on throttle body engages socket tangs on TPS. See Fig. 128. Tighten screws. Manually operate throttle and ensure no binding exists. Reinstall electrical connector.

NOTE: TPS must be installed so it can be rotated a few degrees. If TPS cannot be rotated, reinstall TPS with end of throttle

shaft on other side of TPS socket tangs.

Fig. 128: Installing Throttle Position Sensor (TPS) Courtesy of Chrysler Corp.

TRANSMISSION CONTROL MODULE (TCM) R & I

Removal & Installation (Cherokee)

Ensure ignition is off. Disconnect electrical connector from TCM, located behind right side of instrument panel. See Fig. 129. Remove fastener and TCM from instrument panel. To install, reverse removal procedure.

94F38401

Fig. 129: Transmission Control Module Courtesy of Chrysler Corp.

(TCM) I.D. (Cherokee)

VALVE BODY SOLENOID R & I

Removal

Raise and support vehicle. Remove drain plug and drain

transmission fluid. Remove bolts and oil pan. Remove bolts, oil screen

and gasket.

Disconnect electrical connectors from valve body solenoid.

Mark electrical connector location for reassembly reference if more

than one valve body solenoid is being removed. Remove bolt, valve body

solenoid and "O" ring.

CAUTION: DO NOT allow components to fall from valve body when removing valve body solenoid.

Installation

To install, reverse removal procedure using NEW "O" ring

and NEW gaskets. Tighten valve body solenoid bolt and oil screen bolt

to specification. See TORQUE SPECIFICATIONS.

Ensure magnet is installed in oil pan and does not

interfere with valve body oil tubes. Apply 1/8" bead of Loctite 599

sealant on oil pan mounting flange. Install oil pan. Install and

tighten bolts to specification. See TORQUE SPECIFICATIONS.

Install NEW gasket and drain plug. Tighten drain plug to

specification. See TORQUE SPECIFICATIONS. Fill transmission to proper

fluid level with Mopar Dexron-IIE/Mercon ATF.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

Application Ft. Lbs. (N.m)

Drain Plug 15 (20)

INCH Lbs. (N.m)

Neutral Safety Switch Adjusting Bolt 108 (12.2)

Neutral Safety Switch Retaining Nut 61 (6.9)

Oil Pan Bolt 65 (7.3)

Oil Screen Bolt 84 (9.5)

Speed Sensor Bolt 65 (7.3)

Valve Body Solenoid Bolt 84 (9.5)