ANTI-THEFT SYSTEM

1993 Jeep Cherokee

1993 ACCESSORIES & EQUIPMENT Chrysler Corp. Anti-Theft System

Jeep; Cherokee DESCRIPTION & OPERATION

The Vehicle Theft Alarm (VTA) Module is a logic controlled device that monitors vehicle doors, hood, liftgate and ignition tampering. Alarm activates by sounding horn, flashing all external lights and preventing vehicle engine from running. VTA system arms during normal vehicle lock-up procedure (ignition off, all doors locked with power locks). Security light flashes for 15 seconds during arming process. Security light remains lit during arming process if no signal is received from hood switch.

When the VTA is triggered, horn sounds for 3 minutes while flashing all external lights. Headlights, park and taillights continue to flash for an additional 15 minutes after horn stops. VTA system features a tamper alert function that notifies if vehicle has been tampered with by sounding horn 3 times once a front door is unlocked. The VTA will not arm if door is locked using key or manual lock control.

NOTE: If vehicle battery is disconnected and reconnected, the VTA system enters a power up alarm mode. The headlights, park and taillights will flash. The engine will not run. To exit this mode, the VTA system must be disarmed using key or keyless entry transmitter.

TROUBLE SHOOTING

NOTE: VTA system or VTA system self-test will be inoperative if Powertrain Control Module (PCM), has been replaced within last 20 ignition cycles.

1) System

operation may be verified by entering self-test

mode. To enter

self-test, cycle ignition key to accessory position 3

times,

leaving switch in accessory position. Once in self-test

mode,

headlights, park and taillights

will begin flashing and horn will

sound

twice, verifying their operation.

NOTE: Vehicles equipped with VTA are also equipped with

illuminated entry. Unless illuminated entry system is disabled, it is necessary to wait 30 seconds after each door opening or closure before testing can occur.

2) In

self-test mode, horn will sound once after each of the

following

tests, indicating proper operation.

Beginning

with all doors closed, open and close each

individual door. The

horn will sound each time a door is

opened or closed. Allow one

second between opening and

closing.

Open, then

close hood. Horn will sound upon opening and

closing hood.

Operate power door locks in both directions.

Rotate key

in both door lock cylinders to unlock position.

Horn will sound

as switch closes, and again when it opens.

Allow at least one

second between close and open position.

Cycle

ignition switch to RUN position. Horn will sound and

also take

VTA out of self-test mode.

Activate

remote keyless entry in both lock and unlock

directions.

Horn not

sounding after any of the above operations

indicates a switch

failure, lack of input signal to VTA module or

internal failure

of module.

Check

for continuity at switch. Check for open or shorted

wire

between switch and alarm module. See appropriate wiring diagram

in

the WIRING DIAGRAMS article in the ENGINE PERFORMANCE section.

Check

if PCM has been replaced. When PCM is replaced, it is necessary

to

cycle ignition switch through 20 engine

starts to initialize

system.

Whenever a

VTA system malfunction occurs, verify wire

harness is properly

connected to all connectors before starting normal

diagnosis and

repair procedures. If security lamp comes on and remains

on after

ignition is turned on, CCD bus communication signal with PCM

has

been lost.

CONNECTOR IDENTIFICATION

CONNECTOR IDENTIFICATION DIRECTORY TABLE

Connector Go to Figure

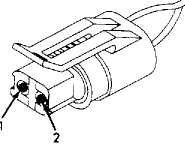

Front Door Key Cylinder Switch See Fig. 1.

Liftgate Key Cylinder Switch See Fig. 2.

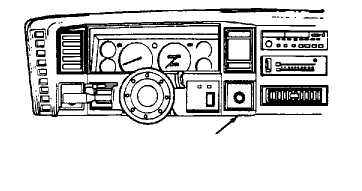

Mechanical Instrument Cluster See Fig. 3.

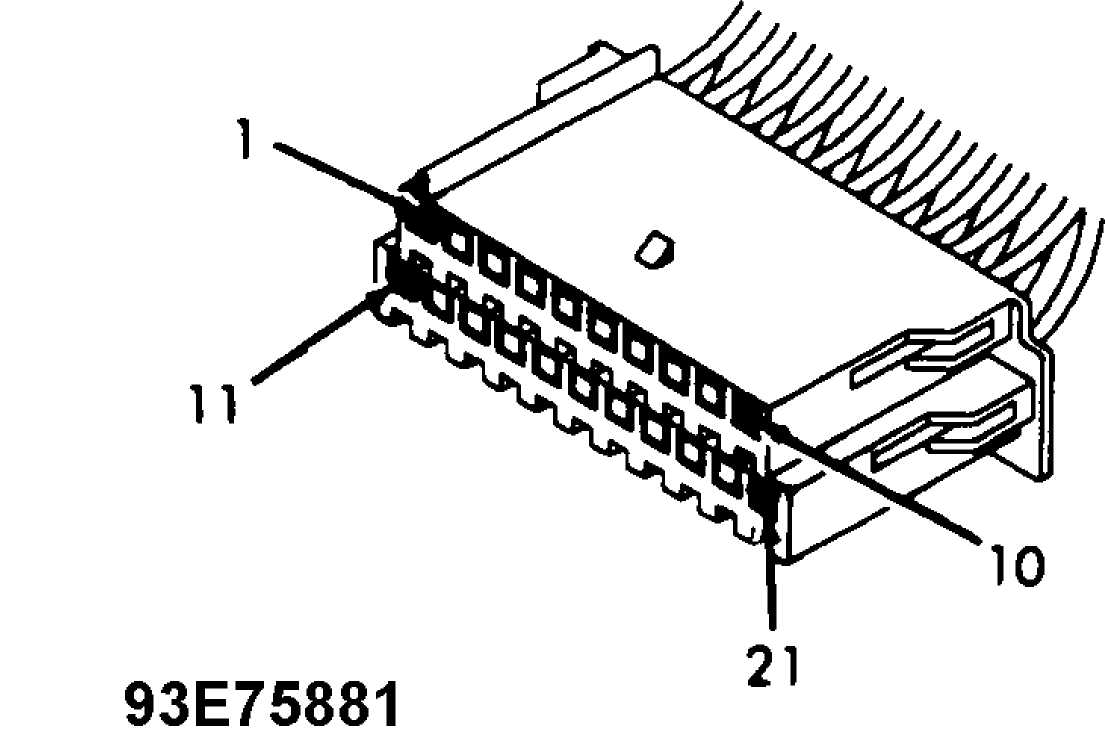

Powertrain Control Module See Fig. 4.

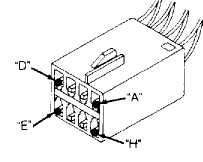

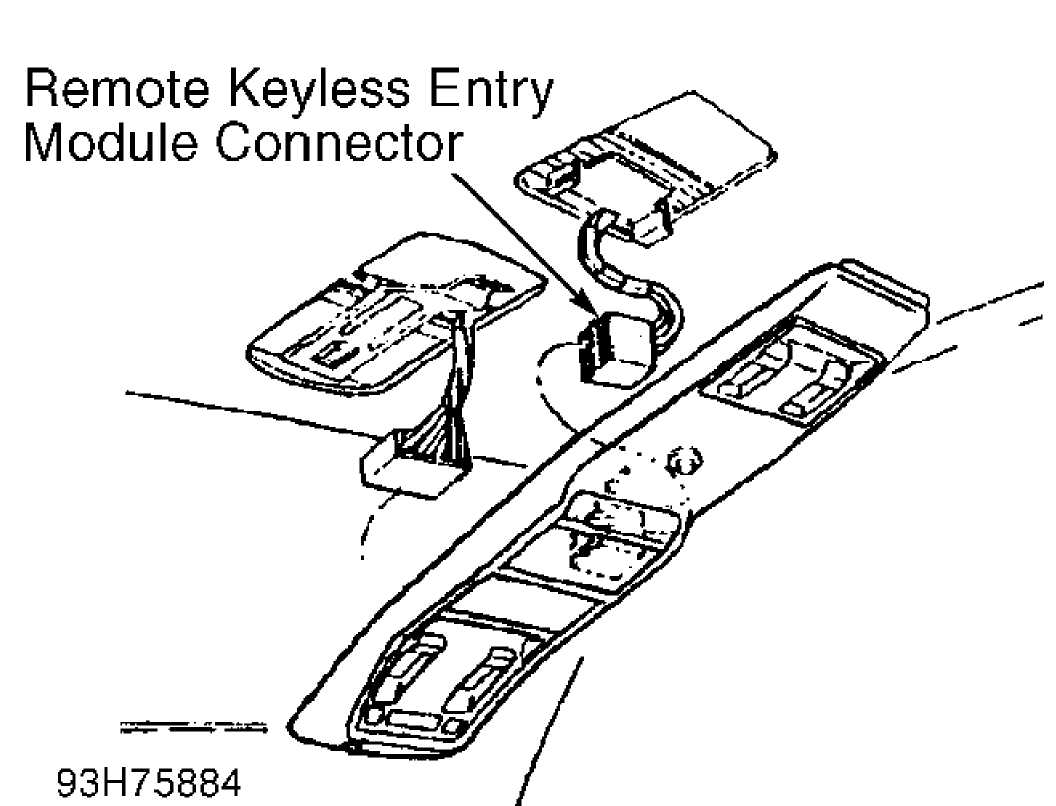

Remote Keyless Entry Module See Fig. 5.

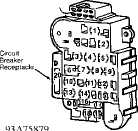

Vehicle Fuse Block See Fig. 6.

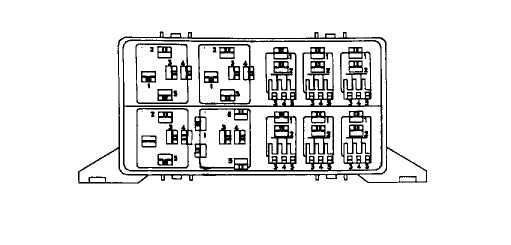

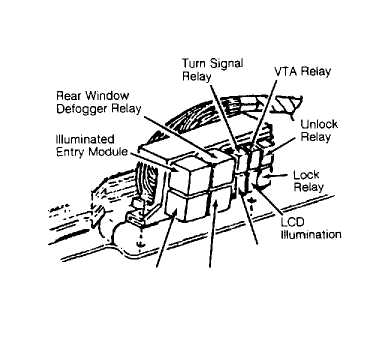

Vehicle Relay Center See Fig. 7.

Vehicle Theft Alarm Module See Fig. 8.

93F75874

Fig. 1: Identifying Front Door Key Cylinder Switch Connector Courtesy of Chrysler Corp.

2

3-

2

3-

93G75875

Fig. 2: Identifying Liftgate Key Cylinder Switch Connector Courtesy of Chrysler Corp.

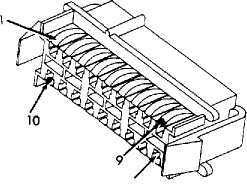

9.╪75876 18

Fig. 3: Identifying Mechanical Instrument Cluster Connector Courtesy of Chrysler Corp.

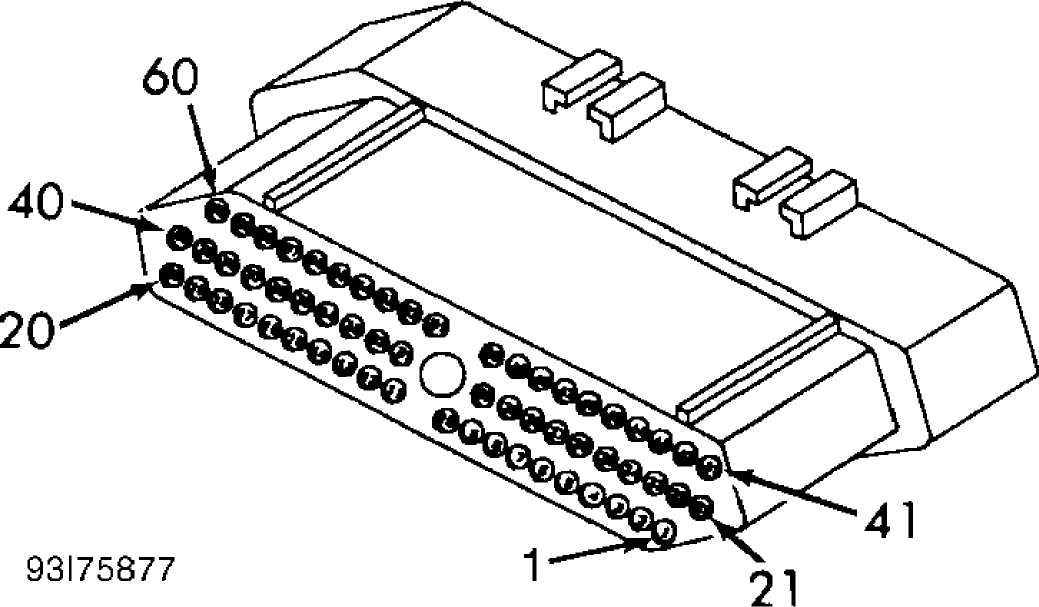

Fig. 4: Identifying Powertrain Control Module Connector Courtesy of Chrysler Corp.

93175878

Fig. 5: Identifying Remote Keyless Entry Module Connector Courtesy of Chrysler Corp.

Fig. 6: Identifying Vehicle Fuse Block Courtesy of Chrysler Corp.

RELAY BLOCK (Mounted Behind Glove Box)

93╧75880

Fig. 7: Identifying Vehicle Relay Center Courtesy of Chrysler Corp.

Fig. 8: Identifying Vehicle Theft Alarm Module Connector Courtesy of Chrysler Corp.

TESTING

NOTE: In the following tests, illustrations are courtesy of

Chrysler Corp. For connector terminal identification, see the CONNECTOR IDENTIFICATION table. For wiring diagrams, the appropriate chassis wiring diagram in WIRING DIAGRAMS article in ENGINE PERFORMANCE section.

CAUTION: Always turn ignition switch to OFF position prior to

NOTE:

disconnecting or connecting any module connector. Once connector is disconnected, ignition can be turned on.

There are no diagnostic or trouble codes for Vehicle Theft Alarm system. Only symptom diagnosis and repair are provided by the manufacturer.

USING DRB-II

NOTE: Although other scan testers are available, manufacturer recommends using DRB-II (Diagnostic Readout Box II) to diagnose system.

WARNING: DO NOT probe connector with an ohmmeter unless specifically instructed in testing procedure. There is a possibility of air bag deployment.

Ensure DRB-II is connected to CCD data link connector located in behind dash on right side of steering column. See Fig. 9. Ensure correct cartridge is installed in DRB-II for vehicle and system being diagnosed. Menu selections will vary depending on vehicle and system being diagnosed. Follow DRB-II screen prompts to actuate, adjust, monitor, reset, test and diagnose system as necessary.

DRB-II is grounded through CCD data link connector, only one volt-ohmmeter test lead is required when using volt-ohmmeter option. DRB-II volt-ohmmeter should only be used when self-diagnostic tests require the use of this option.

If DRB-II has a blank screen or displays RAM TEST FAILURE, CARTRIDGE ERROR, KEY PAD TEST FAILURE, LOW BATTERY or HIGH BATTERY, this indicates a DRB-II failure. To diagnose and correct these conditions, see BODY CONTROL COMPUTER - VEHICLE COMMUNICATIONS article in ENGINE PERFORMANCE.

CCD

DATA LINK CONNECTOR

CCD

DATA LINK CONNECTOR

(Mounted Behind Dash, Right Side Of Column)

93C75871

Fig. 9: Identifying Location Of CCD Data Link Connector Courtesy of Chrysler Corp.

TEST 1A - TESTING SYSTEM FUNCTION

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Connect

DRB-II to data link connector. See Fig. 9. If

DRB-

II displays SELECT SYSTEM, select

VTA MODULE. If DRB-II is blank or

displays anything other than

SELECT SYSTEM, see BODY CONTROL COMPUTER

- VEHICLE

COMMUNICATIONS article in the ENGINE PERFORMANCE section.

If

after selecting VTA MODULE the DRB-II displays NO

RESPONSE, go

to TEST 2A. If after selecting VTA MODULE the DRB-II

screen

does not display NO RESPONSE, disconnect the illuminated

entry

module. See Fig. 10.

Ensure all doors, hood and liftgate are

fully

closed.

H/Lamp

H/Lamp

,_,„,- i Relay <ECE)

Horn Relay power Antenna

RELAY CENTER (Under Glove Box)

93F75882 Fig. 10: Identifying Relay Center Location

If

security light flashes constantly, go to TEST 3A. If

security

light does not flash, switch VTA status to diagnostic using

DRB-II.

If DRB-II does not display TURN IGNITION KEY TO ACC.

POSITION,

go to TEST

4A. If DRB-II displays TURN IGNITION KEY TO ACC. POSITION,

turn

ignition switch to ACC. position.

If DRB-II

displays NO RESPONSE after turning key to ACC.

position, go to

TEST 5A. If after turning key to ACC. position horn

does not

sound, go to TEST 6A. If horn does sound, check if security

light

is flashing. If security light is flashing, check if park

and

headlights are flashing.

Go to TEST

7A if security light is not flashing. Go to

TEST 8A if exterior

lights are not flashing. If exterior lights are

flashing, turn

ignition off and open left front door. Close door. If

horn does

not sound, go to TEST 9A.

If horn

does sound, open right front door. Close door. If

horn does not

sound, go to TEST 9A. If horn does sound, open right

rear door.

Close door. If horn does not sound, go to TEST 9A. If horn

does

sound, open left rear door. Close door. If horn does not sound,

go

to TEST 9A.

If horn

does sound, open hood. Close hood. If horn does

not sound, go to

TEST 10A. If horn does sound, open liftgate. Close

liftgate. If

horn does not sound, go to TEST 11A. If horn does sound,

push

power door lock switch to LOCK position.

If horn

does not sound, go to TEST 12A. If horn does

sound, push power

door lock switch to UNLOCK position. If horn does

not sound, go

to TEST 13A. If horn does sound, rotate key in left

front door

lock to UNLOCK position. If horn does not sound, proceed to

TEST

14A.

If horn

does sound, rotate key in right front door lock to

UNLOCK

position. If horn does not sound, go to TEST 15A. If horn

does

sound, rotate key in liftgate to UNLOCK position. If horn

does not

sound, go to TEST 16A.

If

horn does sound, turn ignition on. If horn does not

sound,

go to TEST 4A. If horn does sound, read vehicle theft alarm

status

with DRB-II. If the DRB-II does not display CURRENT MODE

DISARMED,

go to TEST 1B. If DRB-II does display CURRENT MODE DISARMED,

DRB-II

screen should display ENGINE CONTROLLER: 1) NO

RESPONSE, 2) NO

RESPONSE ?. If

message is displayed, go to TEST 17A.

If

DRB-II displays the message, ENGINE CONTROLLER: 1) OK

TO

RUN ARM VTA, 2) OK TO RUN ENGINE ?,

go to TEST 18A if malfunction

is

caused by keyless entry, arm or disarm. If message is not

displayed,

replace Powertrain Control Module (PCM).

If

keyless entry is working properly, determine if engine

controller

has been replaced. If engine controller has not been

replaced,

system is functioning properly. Engine has to cycle through

20

ignition starts before VTA becomes operational

(assembly plant

alarm override

feature).

TEST 1B - TESTING SYSTEM FUNCTION

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Ensure ignition is off. Turn left door lock to UNLOCK

position and turn ignition on. Using DRB-II, read VTA status. If DRB-II displays CURRENT MODE DISARMED, system is functioning properly. Perform TEST VER-1. If screen does not display CURRENT MODE DISARMED, replace VTA module. Perform TEST VER-1.

TEST 2A - REPAIRING NO RESPONSE

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

1) Ensure ignition switch is off. Disconnect VTA module. See Fig. 11. Using DRB-II in ohmmeter mode, test system ground circuit for resistance at VTA module connector.

Controller

Antilock Brake

Controller

Antilock Brake

Vehicle Theft Alarm Module

(Under Instrument Panel, Right Of Steering Column)

93G75883 Fig. 11: Identifying Vehicle Theft Alarm Location

Check

resistance at terminal No. 21 (Black

wire). If

resistance

is more than 0-15 ohms, repair open

circuit. Perform TEST

VER-1. If

resistance is less than 0-15 ohms, turn

ignition on.

Using

DRB-II in voltmeter mode, check voltage at terminal

No. 8

(Dark Blue/White wire) of VTA module connector.

If voltage is

less than 10 volts, go

to TEST 2B. If voltage is more than 10 volts,

check

ignition voltage at terminal No. 12 (Dark

Blue wire). If voltage

is

less than 10 volts, go to TEST 2C. If

voltage is more than 10

volts,

disconnect DRB-II.

Using

external ohmmeter, check resistance between pin No.

4

(Violet/Brown wire) of CCD data link connector

and terminal No. 9

(Violet/Brown wire)

of VTA module connector. If resistance is more

than 5 ohms, repair open circuit. Perform TEST VER-1. If resistance is less than 5 ohms, check resistance between pin No. 3 (White/Black wire) of CCD data link connector and terminal No. 10 (White/Black wire) of VTA module connector. If resistance is more than 5 ohms, repair open circuit. Perform TEST VER-1. If resistance is less than 5 ohms, replace VTA module. Perform TEST VER-1.

TEST 2B - REPAIRING NO RESPONSE

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate

wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Remove

fuse No. 4 from fuse block and inspect. If

fuse is

open (NG), check resistance

between terminal No. 8 (Dark Blue/

White

wire) of VTA module connector using DRB-II. If resistance

is less than

5 ohms, repair shorted

wire. If resistance is more than 5 ohms,

replace

No. 4 fuse. Perform TEST VER-1.

If

No. 4 fuse is good when removed, check

voltage feed

circuit with DRB-II.

Connect DRB-II to voltage feed terminal of No. 4

fuse

(right side of connector) receptacle. If voltage is less than

10

volts, repair open circuit between

fuse receptacle and terminal No. 8

(Dark Blue/White wire) of VTA module connector. Perform TEST VER-1. If voltage is more than 10 volts, repair open circuit between terminal No. 12 (Dark Blue wire) of VTA module connector and terminal No. 4

(Violet/Brown wire) of wiper circuit breaker receptacle of fuse block. Perform TEST VER-1.

TEST 2C - REPAIRING NO RESPONSE

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

1) Remove

wiper circuit breaker from fuse block. Using DRB-

II, check

voltage at ignition voltage feed, terminal No. 4

(Violet/Brown

wire) of circuit breaker receptacle. If voltage is less

than 10 volts, repair open ignition voltage feed circuit (Violet/Brown wire). Perform TEST VER-1.

If

voltage is more than 10 volts, check

circuit resistance

with DRB-II. Check

resistance at terminal No. 12 (Dark Blue

wire) of

VTA module connector. If

resistance is less than 5 ohms,

repair

ignition voltage feed circuit

(Dark Blue wire) for short to ground.

Replace wiper circuit

breaker. Perform TEST VER-1.

If

resistance is more than 5 ohms, check

resistance

between terminal No. 12

(Dark Blue) of VTA module connector and

terminal

No. 2 of circuit breaker receptacle of

fuse block. If

resistance is less than

5 ohms, replace circuit breaker. If

resistance

is more than 5 ohms,

repair open ignition feed circuit (Dark Blue

wire).

Perform TEST VER-1.

TEST 3A - REPAIRING SECURITY LIGHT FLASHING CONSTANTLY

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

1) Disconnect VTA module. See Fig. 11 in TEST 2A. Using DRB-II, check voltage at arm sense terminal No. 6 (Pink/Orange wire) of VTA module connector. If voltage is less than one volt, replace VTA module. Perform TEST VER-1. If voltage is more than one volt, disconnect remote keyless entry module. See Fig. 12.

Fig. 12: Identifying Remote Keyless Entry Module Location

2) Using DRB-II, check voltage at arm sense circuit terminal No. 6 (Pink/Orange wire). If voltage is more than one volt, repair shorted arm sense (Pink/Orange wire). Perform TEST VER-1. If voltage is less than one volt, replace remote keyless entry module. Perform TEST VER-1.

TEST 4A - REPAIRING IGNITION INPUT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Ensure

ignition is turned off. Disconnect VTA module. Turn

ignition

on. Using DRB-II, check voltage at terminal No. 8

(Dark

Blue/White wire) of VTA module

connector. If voltage is more than 10

volts,

replace VTA module. Perform TEST VER-1.

If

voltage is less than 10 volts, remove No.

4 fuse and

inspect. If fuse is open

(NG), check resistance at terminal No.

8

(Dark Blue/White wire) of VTA module

connector with DRB-II. If

resistance is less than 5 ohms,

repair ignition voltage feed circuit

terminal

No. 8 (Dark Blue/White wire) shorted to

ground. Perform TEST

VER-1.

If

resistance is more than 5 ohms, replace

fuse. If fuse

No. 4 is

not open (good), check voltage feed circuit at fuse No. 4

(right side of receptacle) with DRB-II. If voltage is less than 10 volts, repair open circuit between fuse receptacle and terminal No. 8

(Dark Blue/White wire) of VTA module connector. Perform TEST VER-1. If voltage is more than 10 volts, repair open circuit between pin No. 12

(Dark Blue wire) of VTA module connector and terminal No. 4

(Violet/Brown wire) of wiper circuit breaker of fuse block. Perform TEST VER-1.

TEST 5A - REPAIRING IGNITION INPUT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

1) Ensure ignition is off. Disconnect VTA module. Turn

ignition on. Using DRB-II, check voltage at terminal No. 12 (Dark Blue wire) of VTA module connector. If voltage is more than 10 volts, replace VTA module. Perform TEST VER-1. If voltage is less than 10 volts, remove wiper circuit breaker.

Using

DRB-II, check voltage at terminal No. 4 (Light

Green/Black

wire) of circuit breaker receptacle. If voltage is less

than 10

volts, repair open voltage feed circuit (Light

Green/Black

wire). If voltage is more

than 10 volts, check resistance at

terminal

No. 2 (Light Green/Black wire)

of wiper circuit breaker receptacle and

terminal No. 12

(Dark Blue wire) of VTA module connector.

If

resistance is less than 5 ohms, repair

shorted circuit.

Perform TEST VER-1.

Replace circuit breaker. If resistance is more

than 5

ohms, repair open voltage feed circuit. Perform

TEST VER-1.

TEST 6A - REPAIRING HORN CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

1) Push

horn button on steering wheel. If horn sounds,

disconnect VTA

module. Using DRB-II, check voltage at terminal No. 5

(Black/Red wire) of VTA module connector. If voltage is less than 10 volts, repair open horn relay control circuit (Black/Red wire).

If

voltage is more than 10 volts, check

voltage on fused

battery feed circuit, terminal No. 2

(Gray/Pink wire) of VTA module

connector.

If voltage is less than 10 volts, repair

open fused battery

voltage feed wire.

If voltage is more than 10 volts, replace

VTA

module. Perform TEST VER-1.

If

horn did not sound when pushing steering wheel button,

disconnect

VTA module. Connect jumper wire between horn relay control

wire

(terminal No. 5 of VTA module connector)

and ground. If horn

sounds, replace VTA module. See the

appropriate STEERING COLUMN

SWITCHES article in the

ACCESSORIES/SAFETY EQUIP section for horn

button/wiring

repair.

If

horn does not sound, remove horn relay. See Fig. 10 in

TEST

1A. Using DRB-II, check fused battery feed voltage at terminal

No.

1 of horn relay receptacle. If voltage is

less than 10 volts, go

to

TEST 6B.

If

voltage is more than 10 volts, check

voltage at fused

battery feed terminal

No. 5 (Gray/Pink wire) of horn relay

receptacle.

If voltage is less than 10

volts, repair open fused battery feed

circuit

(Gray/Pink wire). Perform TEST VER-1.

If

voltage is more than 10 volts, check

resistance between

terminal No. 2

(Black/Red wire) of horn relay receptacle and

terminal

No. 5 (Black/Red

wire) of VTA module connector with external ohmmeter.

If resistance is more than 5 ohms, repair open horn control circuit (Black/Red wire). Perform TEST VER-1.

7) If resistance is less than 5 ohms, connect a jumper wire between terminals No. 1 (Pink/Light Green wire) and No. 4 (Dark Green/Red wire) of horn relay receptacle. If horn sounds, replace horn relay. Perform TEST VER-1. If horn does not sound, repair open horn feed circuit (Dark Green/Red wire). Perform TEST VER-1.

TEST 6B - REPAIRING HORN CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Remove

and inspect fuse No. 11. If fuse is open

(NG),

check resistance of fused battery

feed at terminal No. 2 (Gray/Pink

wire)

of VTA module connector with DRB-II. If resistance is less than

5

ohms, repair fused battery feed circuit

(Gray/Pink wire) for short

to vehicle ground. Replace fuse.

Perform TEST VER-1. If resistance is

more than 5 ohms,

replace fuse. Perform TEST VER-1.

If

fuse No. 11 is not open (good), check

voltage on

battery feed side of fuse receptacle (Red/Yellow wire

on left side of

receptacle) using DRB-II. If voltage is more than

10 volts, repair

open fused battery

feed wire. Perform TEST VER-1. If voltage is less

than 10

volts, repair open battery feed wire. Perform

TEST VER-1. Both

wires are Gray/Pink.

TEST 7A - REPAIRING SECURITY INDICATOR LIGHT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

1) Turn ignition on. If security indicator light is

constantly on, go to TEST 7B. If security light is not on constantly, disconnect VTA module. Connect jumper wire between security light control circuit terminal No. 17 (Black/Orange wire) of VTA module connector and vehicle ground.

If

security light illuminates, replace VTA module. If

security light

does not illuminate, disconnect Mechanical Instrument

Cluster

(MIC) Natural color connector. Remove instrument cluster.

See

appropriate INSTRUMENT PANELS article in the

ACCESSORIES/SAFETY EQUIP

section. Visually inspect condition of

instrument cluster circuit

board. Replace circuit board if

damaged. Perform TEST VER-1.

If

circuit board is okay, inspect security indicator light

bulb.

Replace bulb if open (NG). Perform TEST

VER-1. If security

indicator light bulb

is good, check fused battery feed voltage at

terminal No. 10

(Pink wire) of MIC Natural color connector.

If

voltage is less than 10 volts, repair open

fused

battery feed circuit (Pink wire). Perform

TEST VER-1. If voltage is

more than 10 volts,

repair open security indicator light control

(Black/Orange wire). Perform TEST VER-1.

TEST 7B - REPAIRING SECURITY INDICATOR LIGHT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Disconnect VTA module. See Fig. 11 in TEST 2A. If security

indicator light illuminates, repair security indicator light control (Black/Orange wire) for short to ground. Perform TEST VER-1. If security indicator light does not illuminate, replace VTA module. Perform TEST VER-1.

TEST 8A - REPAIRING PARKING LIGHT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

If

headlights do not flash, go to TEST 8B. If headlights

do

flash, turn parking lights on. If parking lights do not

illuminate,

see appropriate STEERING

COLUMN SWITCHES article in the

ACCESSORIES/SAFETY EQUIP section

for repair. If parking lights do

illuminate, disconnect VTA

module. See Fig. 11 in TEST 2A.

Using

DRB-II, check voltage of park/taillight control

circuit

at terminal No. 4 (Dark Blue/Red wire) of

VTA module

connector. If voltage is less than 10 volts,

repair open

park/taillight control (Dark Blue/Red wire).

If

voltage is more than 10 volts, check

voltage of fused

battery feed circuit at terminal No. 2

(Gray/Pink wire) of VTA module

connector using

DRB-II. If voltage is less than 10 volts,

go to TEST

8D. If voltage is more than 10 volts,

check voltage of fused battery

feed circuit at terminal No. 11

(Pink/Light Green wire) of VTA module

connector

using DRB-II. If voltage is less than 10 volts,

go to TEST

8C. If voltage is more than

10 volts, replace VTA module. Perform

TEST

VER-1.

TEST 8B - REPAIRING HEADLIGHT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Switch

headlights on to high beam. If high beam headlights

fail

to illuminate, see appropriate STEERING COLUMN SWITCHES article

in

ACCESSORIES/SAFETY EQUIP section for repair. If high beam

headlights

illuminate, disconnect VTA relay. See Fig. 10 in

TEST 1A.

DO NOT turn off high beam

headlights.

Check VTA relay output voltage at terminal No. 2

(Red/Orange wire) of VTA relay receptacle using DRB-II. If voltage is less than 10 volts, repair open VTA relay output circuit (Red/Orange wire). Perform TEST VER-1. If voltage is more than 10 volts, check fused battery feed voltage at terminal No. 1 (Pink/Light Green wire) of VTA relay receptacle using DRB-II.

3) If voltage is less than 10 volts, go to TEST 8C. If

voltage is more than 10 volts, check resistance of relay ground (Black wire) at terminal No. 3 of VTA relay receptacle using DRB-II. If resistance is more than 20 ohms, repair open VTA relay ground. Perform TEST VER-1.

4) If

resistance is less than 20 ohms, disconnect

VTA module.

See Fig. 11 in TEST 2A.

Using DRB-II, check fused battery feed voltage

at terminal No. 11

(Pink/Light Green wire) of VTA module connector.

If

voltage is less than 10 volts,

repair open fused battery feed circuit

(Pink/Light Green wire). Perform TEST VER-1.

5) If

voltage is more than 10 volts, check fused

battery feed

circuit voltage at terminal

No. 2 (Gray/Pink wire) of VTA

module

connector using DRB-II. If voltage is less than 10

volts, go to TEST

8D. If voltage is more than

10 volts, check VTA relay control

circuit

resistance at terminal No. 18 (Tan/Pink

wire) of VTA module connector

using DRB-II.

If

resistance is less than 5 ohms, repair VTA

relay

control circuit wire for short to

vehicle ground. If resistance is

more

than 5 ohms, check resistance between

terminal No. 5 (Tan/Pink

wire) of VTA

relay control receptacle and terminal No. 18 (Tan/Pink

wire)

of VTA module connector using external ohmmeter.

If

resistance is more than 5 ohms, repair

open VTA relay

control circuit

(Tan/Pink wire). Perform TEST VER-1. If

resistance is

less than 5 ohms,

reconnect VTA relay. Connect jumper wire between

terminal

No. 11 (Pink/Light Green wire) and

terminal No. 18 (Tan/Pink

wire)

of VTA module connector. If headlights illuminate, replace

VTA

module. Perform TEST VER-1. If headlight do not illuminate,

replace

VTA relay. Perform TEST VER-1.

TEST 8C - REPAIRING BATTERY SUPPLY INPUT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Remove

and inspect fuse No. 3. If fuse is open

(NG), check

fused

battery feed circuit resistance at terminal No. 2

(Pink/Light

Green) of VTA module connector

using DRB-II. If resistance is less

than

5 ohms, repair fused battery feed wire for

short to ground.

Replace fuse. If resistance is more than 5

ohms, replace fuse. Perform

TEST

VER-1.

If

No. 3 fuse is good, check fuse No. 3

receptacle (left

side of receptacle) feed

voltage using DRB-II. If voltage is less than

10 volts,

repair open battery feed wire. Perform TEST VER-1. If

voltage

is more than 10 volts, repair open fused

battery feed wire.

Perform TEST VER-1.

TEST 8D - REPAIRING BATTERY SUPPLY INPUT CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Remove

and inspect fuse No. 11. If fuse is open

(NG),

check fused battery feed circuit

resistance at terminal No. 11

(Gray/Pink

wire) of VTA module connector using DRB-II. If resistance

is

less than 5 ohms, repair fused battery

feed wire for short to

ground. Perform

TEST VER-1. Replace fuse. If resistance is more than 5

ohms,

replace fuse. Perform TEST VER-1.

If

No. 11 fuse is good, check fuse No. 11

receptacle (left

side

of receptacle) feed voltage using DRB-II. If voltage is less than

10

volts, repair open battery feed wire. Perform

TEST VER-1. If

voltage is more than 10

volts, repair open fused battery feed

wire.

Perform TEST VER-1.

TEST 9A - REPAIRING DOOR JAMB SENSE CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Ensure all

doors, hood and liftgate are closed. Ensure all

courtesy, dome

and cargo lights function properly. Repair any interior

lights

that are not functioning.

Using DRB-II, read DOOR AJAR status. If status screen does

not display closed (CLSD), go to TEST 9B. If DRB-II displays closed (CLSD) status, disconnect left front door jamb switch. If status screen does not display closed (CLSD), replace door jamb switch. Perform TEST VER-1.

3) If

DRB-II displays closed (CLSD) status, disconnect left

rear

door jamb switch. If status screen does not display closed

(CLSD),

replace door jamb switch. Perform TEST VER-1. If DRB-II

displays closed (CLSD) status, disconnect right front door jamb switch. If status screen does not display closed (CLSD), replace door jamb switch. Perform TEST VER-1.

4) If

DRB-II displays closed (CLSD) status, disconnect right

rear

door jamb switch. If status screen does not display closed

(CLSD),

replace door jamb switch. Perform TEST VER-1. If DRB-II

displays closed (CLSD) status, disconnect liftgate latch sense switch. See Fig. 13. If status screen does not display closed (CLSD), replace liftgate latch sense switch. Perform TEST VER-1.

Key

Cylinder Switch Connector

Key

Cylinder Switch Connector

93175885 Fig. 13: Identifying Liftgate Latch Switch Location

If

DRB-II displays closed (CLSD) status, disconnect VTA

module. See

Fig. 11 in TEST 2A. Using DRB-II, check

door jamb sense

circuit voltage at

terminal No. 3 (Yellow wire) of VTA

module. If

voltage is less than 10

volts, repair open door jamb sense wire.

Perform

TEST VER-1.

If

voltage is more than 10 volts, check

resistance of

liftgate latch sense

(Violet/Yellow wire) at terminal No. 1 of

VTA

module connector using DRB-II. If resistance is less than 5

ohms,

repair liftgate latch sense wire for

short to ground. Perform TEST

VER-1.

If

resistance is more than 5 ohms, determine

if any

previous repairs were done.

Replace VTA module if no repairs were

done.

Perform TEST VER-1. If repairs were done, perform TEST VER-1.

TEST 9B - REPAIRING DOOR JAMB SENSE CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Disconnect VTA module. See Fig. 11 in TEST 2A. Using DRB-II, check door jamb sense circuit voltage at terminal No. 3 (Yellow wire) of VTA module connector. If voltage is less than 10 volts, repair open door jamb sense wire. Perform TEST VER-1. If voltage is more than 10 volts, replace VTA module. Perform TEST VER-1. See Fig. 11 in TEST 2A.

TEST 10A - REPAIRING HOOD AJAR SENSE CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram

in the WIRING DIAGRAMS section.

Ensure

hood is closed and aligned properly. Using DRB-II,

read

HOOD AJAR status. If DRB-II does not display closed (CLSD)

status,

go to TEST 10B. If displays closed (CLSD) status, disconnect

hood

ajar switch. Using DRB-II, check resistance of hood ajar

sense

circuit at terminal No. 20 (Brown/Tan

wire) of VTA module connector.

If

resistance is less than 5 ohms, repair

hood ajar sense

wire for short to

ground. Perform TEST VER-1. If resistance

is more

than 5 ohms,

replace VTA module. Perform TEST VER-1.

TEST 10B - REPAIRING HOOD AJAR CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Disconnect

hood ajar switch. Connect jumper wire between

hood ajar sense

wire (at switch) and vehicle ground. Using DRB-II,

read HOOD AJAR

switch status. If screen displays closed (CLSD),

replace switch.

If DRB-II screen does not display closed (CLSD),

connect jumper

wire between hood ajar sense wire (at VTA module

connector) and

vehicle ground.

Ensure

connector is connected to VTA module. Using DRB-II,

read HOOD

AJAR switch status. If status screen displays closed, repair

open

hood ajar sense wire. Perform TEST VER-1. If screen does not

display

closed, replace VTA module. Perform TEST VER-1.

TEST 11A - REPAIRING LIFTGATE LATCH SENSE CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Ensure all

doors, hood and liftgate are properly closed

and aligned. VTA

system should still be diagnostic mode.

Using

DRB-II, read DOOR AJAR status screen. If screen

displays

closed (CLSD), go to TEST 9A. If status

screen does not

display closed (CLSD),

open liftgate and turn on cargo light. If horn

sounds, system is

functioning properly. Cargo light switch must be in

ON

position to fully arm VTA system. Return back to TEST 1A.

If

horn does not sound, disconnect liftgate latch switch

connectors.

Using DRB-II, check resistance of latch switch ground

wire. If

resistance is more than 5 ohms, repair

open latch switch

ground wire. Perform TEST VER-1. If resistance

is less than 5 ohms,

connect jumper

wire between liftgate latch switch connectors.

Using

DRB-II, read DOOR AJAR status. If status screen

displays closed

(CLSD), replace liftgate latch switch. Perform TEST

VER-1. If

status screen does not display closed (CLSD), connect jumper

wire

between ground (Black wire) and latch switch sense

(Violet/Yellow

wire).

Using

DRB-II, read DOOR AJAR status. If screen does not

display closed

(CLSD), replace VTA module. If status screen does

display closed

(CLSD), disconnect VTA module. Using DRB-II, check

liftgate

latch sense circuit voltage at terminal No. 1

(Violet/Yellow

wire)

of VTA module connector. If voltage is more than 10

volts,

replace cargo light switch. Perform

TEST VER-1. If voltage is less

than 10 volts,

repair open liftgate latch sense wire. Perform TEST

VER-1.

TEST 12A - REPAIRING DOOR LOCK SENSE CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Determine

that power doors locks are functioning properly.

Repair door

locks that are not functioning properly.

Disconnect

VTA module. See Fig. 11 in TEST 2A. Using

DRB-

II, check lock switch sense (Orange/Violet wire) voltage at

terminal

No. 15 of VTA module

connector. While measuring voltage, push power

lock

switch to LOCK position.

If

voltage is more than 10 volts, replace VTA

module.

Perform TEST VER-1. If

voltage is less than 10 volts, repair open

lock

switch sense circuit (Orange/Violet wire). Perform TEST

VER-1.

TEST 13A - REPAIRING DOOR UNLOCK SENSE CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Determine

that power doors locks are functioning properly.

Repair door

locks that are not functioning properly.

Disconnect

VTA module. See Fig. 11 in TEST 2A. Using

DRB-

II, check unlock switch sense

voltage at terminal No. 16 (Pink/Violet

wire)

of VTA module connector. While measuring voltage, push power

lock

switch to UNLOCK position.

If

voltage is more than 10 volts, replace VTA

module.

Perform TEST VER-1. If voltage

is less than 10 volts, repair open

unlock

switch sense circuit (Pink/Violet wire). Perform TEST VER-1.

TEST 14A - REPAIRING LEFT DOOR KEY CYLINDER CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status. If

DRB-II status screen displays CIRCUIT CLOSED (CLSD), go

to

TEST 15B. If screen does not display

CIRCUIT CLOSED (CLSD), disconnect

left front door switch

connector.

Connect

jumper wire across both terminals of connector.

Using DRB-II,

read DOOR KEY CYLINDER SWITCH (DR KEY CYL:) status. If

status

screen displays CIRCUIT CLOSED (CLSD), replace

left front door

key cylinder switch.

Perform TEST VER-1.

If

DRB-II screen does not display CIRCUIT CLOSED (CLSD),

connect

jumper wire between right terminal No. 2 (Light

Green/Orange

wire) of left front door

switch connector and vehicle ground. Using

DRB-II,

read DOOR KEY CYLINDER SWITCH (DR KEY CYL:) status.

If

screen displays CIRCUIT CLOSED (CLSD), repair switch

ground

wire for open to ground. Perform TEST VER-1. If DRB-II screen

does

not display CIRCUIT CLOSED (CLSD), connect

jumper wire between

terminal No. 7

(Light Green/Orange wire) of VTA module connector

and

vehicle ground. DO NOT disconnect

VTA module connector.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status. If

screen displays CIRCUIT CLOSED (CLSD), repair open disarm

sense

circuit (Light Green/Orange wire). Perform TEST VER-1. If

DRB-II

screen does not display CIRCUIT CLOSED (CLSD), replace VTA

module.

Perform TEST VER-1.

TEST 15A - REPAIRING RIGHT DOOR KEY CYLINDER CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status. If

DRB-II status screen displays CIRCUIT CLOSED (CLSD), go

to

TEST 15B. If screen does not display

CIRCUIT CLOSED (CLSD), disconnect

right front door switch

connector.

Connect

jumper wire across both terminals of connector.

Using DRB-II,

read DOOR KEY CYLINDER SWITCH (DR KEY CYL:) status. If

status

screen displays CIRCUIT CLOSED (CLSD), replace

right front door

key cylinder switch.

Perform TEST VER-1.

If

DRB-II screen does not display CIRCUIT CLOSED (CLSD),

connect

jumper wire between right terminal No. 2 (Dark

Green/Orange

wire) of right front door switch connector and

vehicle ground. Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR

KEY CYL:) status.

If

screen displays CIRCUIT CLOSED (CLSD), repair switch

ground wire

for open to ground. Perform TEST VER-1. If DRB-II screen

does not

display CIRCUIT CLOSED (CLSD), connect

jumper wire between

terminal No. 14

(Dark Green/Orange wire) of VTA module connector

and

vehicle ground. DO NOT disconnect

VTA module connector.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status.

If screen displays CIRCUIT CLOSED (CLSD), repair open disarm

sense

circuit (Dark Green/Orange wire). Perform

TEST VER-1. If DRB-II

screen does not

display CIRCUIT CLOSED (CLSD), replace VTA module.

Perform

TEST VER-1.

TEST 15B - REPAIRING DOOR KEY CYLINDER CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Disconnect

left front door key cylinder switch connector.

Using DRB-II, read

DOOR KEY CYLINDER SWITCH (DR KEY CYL:) status. If

DRB-II status

screen does not display CIRCUIT CLOSED (CLSD), replace

left

front door key cylinder switch. If DRB-II screen displays

CIRCUIT

CLOSED (CLSD), disconnect

liftgate key cylinder switch.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status. If

status screen does not display CIRCUIT CLOSED (CLSD),

replace

liftgate key cylinder switch. Perform TEST VER-1. If DRB-II

screen

displays CIRCUIT CLOSED (CLSD), disconnect

right front door key

cylinder switch.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status. If

DRB-II screen does not display CIRCUIT CLOSED (CLSD),

replace

right front door key cylinder switch. Perform TEST VER-1. If

screen

displays CIRCUIT CLOSED (CLSD), disconnect

remote keyless entry

module. See Fig.

12 in TEST 3A.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status. If

screen does not display CIRCUIT CLOSED (CLSD), replace

remote

keyless entry module. Perform TEST VER-1. If DRB-II screen

displays

CIRCUIT CLOSED (CLSD), disconnect VTA module. See Fig. 11

in

TEST 2A.

Using

DRB-II, check resistance of disarm sense circuit at

terminal

No. 7 (Light Green/Orange wire) of VTA

module connector. If

resistance is less than 5 ohms,

repair disarm sense (Light

Green/Orange wire) for short to

ground. Perform TEST VER-1.

If

resistance is more than 5 ohms, check

resistance of

disarm sense circuit

(right front) at terminal No. 14 (Dark

Green/Orange wire) of VTA module connector. If resistance is less than 5 ohms, repair disarm sense (Dark Green/Orange wire) for short to ground. Perform TEST VER-1. If resistance is more than 5 ohms, replace VTA module. Perform TEST VER-1.

TEST 16A - REPAIRING LIFTGATE KEY CYLINDER CIRCUIT

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status. If

DRB-II status screen displays CIRCUIT CLOSED (CLSD), go

to

TEST 15B. If screen does not display

CIRCUIT CLOSED (CLSD), disconnect

liftgate key cylinder switch

connector.

Connect

jumper wire across terminals No. 1 and 3

of

connector. Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status.

If status screen displays CIRCUIT CLOSED (CLSD), replace

liftgate

key cylinder switch. Perform TEST VER-1.

If

DRB-II screen does not display CIRCUIT CLOSED (CLSD),

connect

jumper wire between right terminal No. 3 (Light

Green/Orange

wire) of liftgate key

cylinder switch connector and vehicle ground.

Using DRB-II, read

DOOR KEY CYLINDER SWITCH (DR KEY CYL:) status.

If

screen displays CIRCUIT CLOSED (CLSD), repair switch

ground wire

for open to ground. Perform TEST VER-1. If DRB-II screen

does not

display CIRCUIT CLOSED (CLSD), connect

jumper wire between

terminal No. 7

(Light Green/Orange wire) of VTA module connector

and

vehicle ground. DO NOT disconnect

VTA module connector.

Using

DRB-II, read DOOR KEY CYLINDER SWITCH (DR KEY CYL:)

status.

If screen displays CIRCUIT CLOSED (CLSD), repair open disarm

sense

wire (Light Green/Orange). Perform TEST VER-1. If DRB-II screen

does

not display CIRCUIT CLOSED (CLSD), replace VTA module. Perform

TEST

VER-1.

TEST 17A - REPAIRING NO RESPONSE FROM PCM

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Turn

ignition to OFF. Disconnect the PCM module connector.

See

Fig. 14. Disconnect the VTA module

connector as shown in TEST 2A,

Fig. 11. Using

an external ohmmeter, check resistance of CCD (+) bus

circuit

between terminal No. 26 (Violet/Brown

wire) of PCM module

connector and terminal No. 9

(Violet/Brown wire) of VTA module

connector.

If

resistance is more than 5 ohms, repair

open CCD (+) bus

(Violet/Brown

wire). If resistance is less than 5

ohms, check

resistance

of CCD (-) bus circuit between terminal

No. 46 (White/Black

wire)

of PCM module connector and terminal No. 10 (White/Black

wire)

of VTA module connector.

If

resistance is more than 5 ohms, repair

open CCD (-) bus

(White/Black

wire). Perform TEST VER-1. If resistance

is less than 5

ohms, replace PCM

module. See Fig. 14. Perform TEST VER-1.

Fig. 14: Identifying Powertrain Control Module Location

TEST 18A - REPAIRING ARM SENSE CIRCUIT FROM REMOTE KEYLESS

ENTRY MODULE

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

If

malfunction is with disarm system, go to TEST 18B.

Disconnect

Remote Keyless Entry (RKE) module. See Fig. 12 in

TEST 3A.

Using DRB-II, check fused

battery feed voltage at terminal "A" (Pink

wire) of RKE

module connector. If less than 10 volts,

repair open

fused battery feed circuit (Pink wire).

Perform TEST VER-1.

If

voltage is more than 10 volts, check

resistance of

system ground at terminal "H" (Black

wire) of RKE module connector

using

DRB-II. If resistance is more than 15 ohms,

repair open system

ground (Black wire).

Perform TEST VER-1. If resistance is less than 15

ohms,

check resistance of arm sense circuit at terminal "F"

(Pink/Orange

wire) of RKE module connector using DRB-II.

If resistance is less than 5 ohms, repair arm sense

circuit (Pink/Orange wire) for short to ground. Perform TEST VER-1. If resistance is more than 5 ohms, connect jumper wire between fused battery feed terminal "A" (Pink wire) and arm sense terminal "F"

(Pink/Orange wire) of RKE module connector. If security light flashes, replace RKE module. Perform TEST VER-1.

4) If

security light does not flash, disconnect VTA module.

Using

external ohmmeter, check resistance of arm sense circuit.

Connect

ohmmeter between terminal No. 6 (Pink/Orange

wire) of VTA

module connector and

terminal "F" of RKE module connector. If

resistance is

more than 5 ohms, repair open arm sense

(Pink/Orange

wire). Perform TEST VER-1.

If resistance is less than 5 ohms,

replace

VTA module. Perform TEST VER-1.

TEST 18B - REPAIRING DISARM SENSE CIRCUIT FROM REMOTE KEYLESS

ENTRY MODULE

NOTE: For connector terminal identification, refer to the CONNECTOR IDENTIFICATION table. For appropriate wiring diagram, see appropriate chassis wiring diagram in the WIRING DIAGRAMS section.

Determine

if all courtesy, dome and cargo lights are

functioning properly.

Repair interior lights that are not functioning

properly.

Disconnect

Remote Keyless Entry (RKE) module. See Fig. 12

in

TEST 3A. Using DRB-II, check courtesy

light control circuit voltage

at

terminal "C" (Violet/Orange wire) of RKE module connector.

If

voltage is less than 10 volts,

repair open courtesy light control

circuit

(Violet/Orange wire). Perform TEST VER-1. If voltage is more

than

10 volts, replace RKE module. Perform TEST

VER-1.

TEST VER-1 - VERIFICATION TEST

Verify

system operation. Ensure all doors, hood and

liftgate

are closed. Open driver’s door. Remove ignition key from

vehicle.

Lock all doors with power door lock switch. Close driver’s

door.

If instrument panel theft alarm "SET" light flashed,

system is

operational and verified. If

"SET" light did not flash, 20 engine

start

cycles have not occurred or theft alarm system is

malfunctioning.

Determine

if security light is flashing. If light is not

flashing, go to

TEST 1A. If light is flashing, system is functioning

properly

REMOVAL & INSTALLATION

Information is not provided from manufacturer.

WIRING DIAGRAM

See appropriate wiring diagram in the WIRING DIAGRAMS article in the ENGINE PERFORMANCE section.