Ā

1993 Jeep Cherokee

1983-96 TRANSFER CASES

Chrysler Corp., GM Corp., Jeep - New Process 207 & 231

Dodge; B1500 & Dakota

GMC/Chevrolet; "T" Series (Blazer & Jimmy)

Jeep; Cherokee, Comanche, Grand Cherokee, Wagoneer, Wrangler

IDENTIFICATION

Transfer case can be identified by an I.D. tag, located on rear case. I.D. tag provides model number, serial number and low range ratio. Date of manufacture is the serial number (I.D. number). This information is necessary when ordering parts.

DESCRIPTION

Model 231 transfer case is a part time, chain-driven, 4-position unit with 2-piece aluminum case. Torque input in 4WD high and low range is undifferentiated. 2WD operation is achieved by a vacuum shift motor. Shift motor disconnects right front axle when 2WD is selected. Vacuum shift motor is controlled by a vacuum switch located on front of transfer case and actuated by shift sector.

ADJUSTMENTS

GEARSHIFT LINKAGE

Chrysler Corp.

Shift transfer case to 2H position. Raise and support vehicle. Loosen lock bolt at trunnion. Ensure linkage rod slides freely in trunnion. Verify transfer case range lever is fully engaged in 2H position. Tighten lock bolt at trunnion. Lower vehicle. Check shift linkage operation. Ensure transfer case shifts into and operates properly in all gear ranges.

General Motors

Remove shift lever knob retainer. Remove shift lever knob. Remove floor console. Place shift lever in Neutral. Pry control cable end from shift lever. Loosen control cable lock nut. Check transfer case to ensure it is in Neutral. Ensure shift lever is in Neutral. Turn shift lever end of cable in or out as needed until it is aligned with shift lever. Install control cable on shift lever. Tighten control cable lock nut.

Jeep

Shift transfer case to 4L position. Raise and support vehicle. Loosen lock bolt at trunnion. Ensure linkage rod slides freely in trunnion. Verify transfer case range lever is fully engaged in 4L position. Tighten lock bolt at trunnion. Lower vehicle. Check shift linkage operation. Ensure transfer case shifts into and operates properly in all gear ranges.

TESTING

VACUUM SWITCH

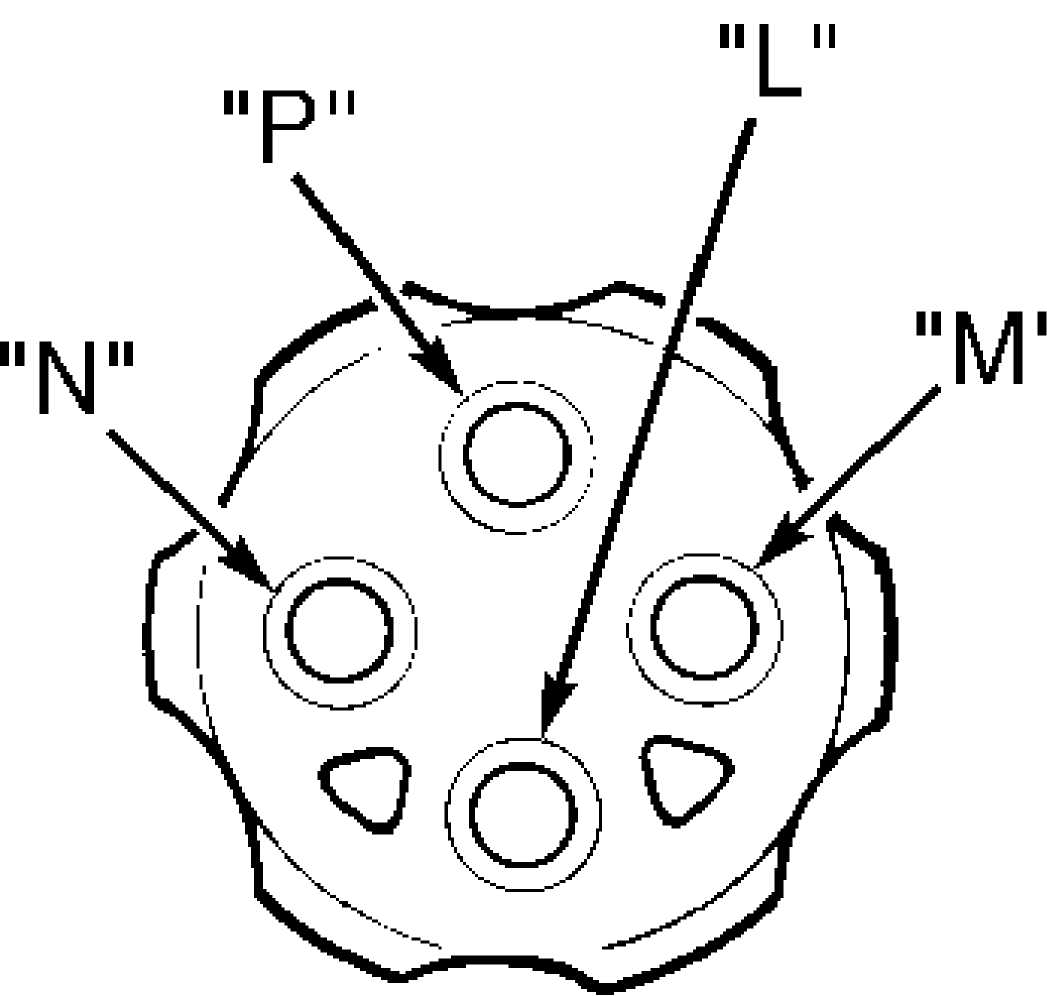

Shift to 2WD position. Locate vacuum switch on front of

transfer case. Apply 15 in. Hg vacuum to "L". See Fig. 1. Vacuum should be present at "M". Connect a vacuum gauge to "N". Shift to 4WD position. Apply vacuum to "L". Vacuum should be present at "N". If switch fails any test, replace switch.

92F13081

Fig. 1: Testing Vacuum Switch Courtesy of Chrysler Corp.

TROUBLE SHOOTING

SYMPTOM DIAGNOSIS

Will Not Shift Or Difficult To Shift Into Gear Vehicle speed too high; slow vehicle to 2-3 MPH to shift. Vehicle operated too long on dry paved surface; stop vehicle and place in Reverse or Neutral to relieve driveline torque. Ensure transfer case external linkage is not binding. Ensure correct fluid is used. Internal parts may be worn or damaged.

Noisy In All Gears

Check fluid level. Ensure correct fluid is used. If fluid is okay, locate possible internal mechanical problem.

Jumps Out Of Gear Or Noisy In 4WD

Transfer case not completely in gear; check shift linkage. Range fork damaged. Shift fork pads are worn or shift fork binding. Low range gear worn.

Fluid Leaking From Vent Or Seals

Transfer case overfilled. Vent plugged. Output shaft seals are damaged or not installed properly.

ON-VEHICLE SERVICE

FRONT OIL SEAL

Removal & Installation

1) Mark front drive shaft and flange for installation

alignment reference. Remove front drive shaft. Remove flange. Discard washer and nut. Using a screwdriver, carefully remove oil seal. Ensure seal contact surface is clean.

2) Apply ATF to seal lip and flange seal surface. Install NEW

oil seal. Install flange and NEW washer and nut. Tighten nut to

specifications. See TORQUE SPECIFICATIONS. Install front drive shaft

using alignment marks. Check transfer case fluid.

EXTENSION HOUSING OIL SEAL & BUSHING

Removal & Installation

1) Mark rear drive shaft and flange for installation

alignment reference. Remove rear drive shaft. Tap extension housing in a clockwise direction and remove extension housing. DO NOT pry on extension housing. Using a screwdriver, remove oil seal from extension housing.

2) Using bushing driver, replace bushing in extension

housing. Install NEW extension housing oil seal. Apply silicone

sealant to extension housing mating surface. Install extension

housing. To complete installation, reverse removal procedure.

REMOVAL & INSTALLATION

TRANSFER CASE

Removal

Shift transfer case into 4H and disconnect battery

negative cable. Raise vehicle, remove skid plate and drain fluid.

Mark front and rear output shaft yokes to drive shafts for

reassembly reference. Support transfer case and remove rear

crossmember. Remove drive shafts.

Disconnect vehicle speed sensor electrical connector and

vacuum (hoses) harness at transfer case. Remove shift lever or linkage

rod from case. Remove transfer case attaching bolts. Remove transfer

case from vehicle.

Installation

Clean all old gasket material from transmission and

transfer case mating surfaces. Position NEW gasket on transfer case

with orientation tab at upper left bolt hole.

Install transfer case, aligning splines of input shaft

with transmission. Slide transfer case forward until seated against

transmission. Install transfer case attaching bolts and tighten to

specification. See TORQUE SPECIFICATIONS. Install rear crossmember.

Attach shift lever and connect speed sensor electrical

connector and vacuum harness at transfer case. Using reference marks

made during removal, reinstall front and rear drive shafts. Refill

transfer case. Install skid plate and lower vehicle. Connect negative

battery cable. Road test vehicle.

TRANSFER CASE DISASSEMBLY

Remove front companion yoke. See Fig. 2 or 3. Discard

washer and nut. Shift transfer case to 4L and remove extension

housing. Remove rear bearing snap ring. Using 2 screwdrivers under

each tab, remove retainer housing. Remove rear case and oil pump as an

assembly.

Remove oil pump pick-up screen and tube from rear case.

Remove oil pump. Remove "O" ring from oil pump and discard. DO NOT

separate oil pump halves. Pump must be replaced as an assembly if

necessary.

Remove mode spring. Using a soft hammer, tap front output

shaft upward and remove with drive chain as an assembly. Remove

mainshaft, mode fork and shift rail as an assembly. Remove mode fork

and shift rail from synchronizer sleeve.

Mark synchronizer sleeve position for reassembly

reference. Remove synchronizer sleeve from mainshaft. Remove

synchronizer hub snap ring. Remove synchronizer hub, stop ring and

drive sprocket. Slide range fork pin out of sector.

Remove range fork and shift hub as an assembly. Remove

range lever from sector shaft. Remove shift sector, bushing and "O"

ring. Remove shift detent pin, spring and plug. Remove front bearing

retainer. Remove input gear snap ring.

Press input and low range gear assembly from input gear

bearing. Remove low range gear snap ring. Remove input gear retainer,

thrust washers and input gear from low range gear.

Remove all oil seals. Remove magnet from front case.

Remove front bearing snap ring. Using a plastic hammer, remove front

bearing. Press input gear bearing from front case.

Using slide hammer and internal puller, remove input gear

pilot bearing. Press bearings from drive sprocket. Using internal

puller and slide hammer, remove output shaft rear bearing.

24 25 26

Front Companion Flange Nut

Front Companion Flange Seat

Front Companion Flange

Front Output Shaft Seal

Snap Ring

Front Output Shaft Bearing

Case Plug

Vacuum Switch

Gasket

Front Case

Low Range Lock Plate

Input Gear Seal

Input Gear Front Bearing

Input Gear Rear Bearing

Thrust Bearing Washer

Input Gear Thrust Bearing

Input Gear

Input Gear Cup Plug

Mainshaft Pilot Bearing

Planetary Thrust Washer

Annulus Gear

Front Thrust Ring

Planetary Gear

Rear Thrust Ring

Planetary Retaining Ring

Snap Ring

Synchronizer Front Spring

Synchronizer Struts

Synchronizer Hub

Synchronizer Rear Spring

Synchronizer Sleeve

Synchronizer Stop Ring

Mainshaft

Thrust Washer

Drive Sprocket Rear Bearing

Drive Sprocket Front Bearing

Drive Chain

Drive Sprocket

Front Output Shaft Bearing

Front Output Shaft

Range Fork Pads

Range Fork Front Bushing

Range Fork

Range Fork Rear Bushing

Shift Rail

Shift Rai! Bracket

Mode Fork Pads

Mode Fork Front Bushing

Fig. 2: Exploded View Of Transfer Case (Model 207) Courtesy of Chrysler Corp.

Mode Fork

Mode Fork

Mode Fork Cup

Mode Fork Spring

Mode Fork Rear Bushing

Rear Case

Oil Pump

Speedometer Drive Gear

Pump Housing Seal

Oil Pump Housing

Mainshaft Rear Bearing

Rear Bearing Snap Ring

Rear Retainer

Vent Assembly

Extension Housing

Extension Housing Seal

Fill Plug

Drain Plug

Magnet

Shift Sector

Spacer

Sector Detent Spring

Detent Spring Bolt

Range Lever Nut

Range Lever

"O" Ring Retainer

"O" Ring

95H2941C

Front Companion Yoke,

Front Companion Yoke,

Nut, Washer & Seal

Detent Plug, Spring & Pin

Front Retainer & Seal

Front Case

Vacuum Switch & Seal

Vent Assembly

Input Gear Bearing & Snap Ring

Low Range Gear Snap Ring

Input Gear Retainer

Low Range Gear Thrust Washers

Input Gear

Input Gear Pilot Bearing

Low Range Gear

Range Fork Shift Hub

Synchronizer Hub Snap Ring

Synchronizer Hub Springs

Synchronizer Hub & Inserts

Synchronizer Sleeve

Synchronizer Stop Ring

Snap Ring

Output Shaft Front Bearing

Front Output Shaft

Drive Sprocket

Drive Chain

Drive Sprocket Bearings

Output Shaft Rear Bearing

Mainshaft

Oil Seal

Oil Pump Assembly

Rear Bearing

Snap Ring

Rear Case

Fill Plug

Drain Plug

Rear Retainer

Extension Housing

Bushing

Oil Seal

Oil Pick-Up Screen

Tube Connector

Oil Pick-Up Tube

"O" Ring

Magnet

Range Lever Nut & Washei

Range Lever

"O" Ring & Seal

Sector

Mode Spring

Mode Fork

Mode Fork Pads

Range Fork Pads

Range Fork Bushings

Range Fork

92 H13083

Fig. 3: Exploded View Of Transfer Case (Model 231) Courtesy of Chrysler Corp.

CLEANING & INSPECTION

Clean all parts with solvent. Dry with compressed air. Replace all oil seals, "O" rings and snap rings. Check all parts for wear or damage. Replace all worn or damaged parts. If low range annulus gear inside front case is damaged or worn, front case and gear must be replaced as an assembly. Replace oil pump as an assembly if any part is damaged or worn.

TRANSFER CASE REASSEMBLY

NOTE: When installing bearings, ensure bearing bores are aligned with oil feed holes.

1) Lubricate all parts with Dexron III before installing.

Install output shaft front bearing with NEW snap ring. Install output shaft oil seal in front case. Install snap ring on NEW input gear bearing. See Fig. 2 or 3.

Press input gear bearing so snap ring is seated against

case. Using press, install NEW input gear pilot bearing. Assemble low

range gear, input gear, thrust washers and retainer.

Install snap ring. Ensure snap ring is seated in low range

gear groove. Start input gear shaft into bearing in front case. Press

input shaft gear into bearing.

CAUTION: DO NOT press against end surfaces of gear. Failure to use proper size tool could lead to gear case or thrust washer damage.

Install input gear snap ring. Install oil seal in front

bearing retainer. Apply a 1/8" bead of silicone sealant to retainer

mating surface. Align oil channel in retainer with oil feed hole in

case. Install retainer on case. Tighten bolts to specification.

Install sector shaft "O" ring and bushing. Install range

sector in case. Install range lever and nut. Install detent, detent

spring and plug. Tighten to specification. See TORQUE SPECIFICATIONS.

Install NEW pads and fork rail bushings on range fork. Install range

fork and shift hub.

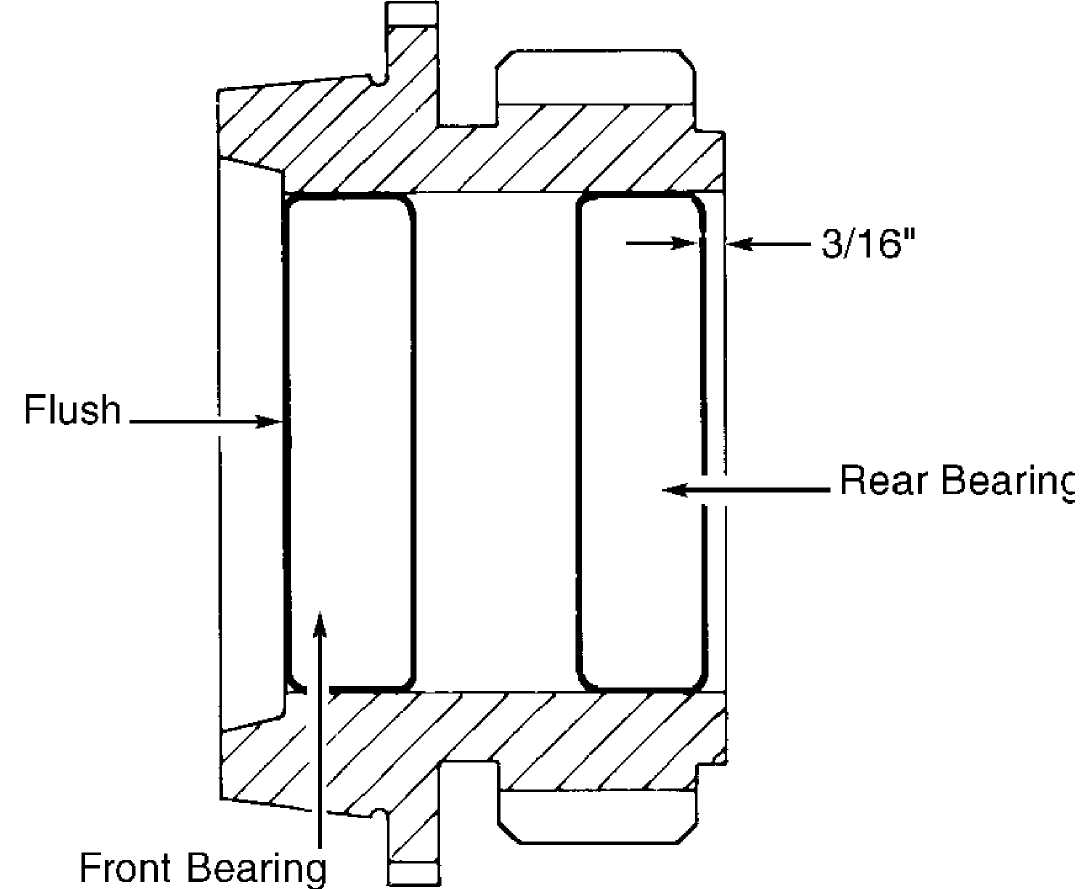

Ensure range fork pin is engaged with range sector slot.

Press front bearing in drive sprocket until bearing is flush with bore

edge. Install rear bearing until bearing is 3/16" below bore edge. See

Fig. 4.

Install inserts and spring in synchronizer hub. Install

sprocket on mainshaft. Install synchronizer stop ring on mainshaft.

Ensure stop ring is seated. Install synchronizer hub on mainshaft.

Align and seat hub inserts on stop ring lugs. Install synchronizer hub

snap ring.

Install synchronizer sleeve on hub. Ensure sleeve is

positioned so beveled spline ends are facing stop ring. Ensure sleeve

tooth is aligned (centered) over each synchronizer strut. Gear clash

will occur if strut and sleeve teeth are misaligned. Install NEW pads

on mode fork. Engage mode fork in synchronizer sleeve. Install

mainshaft and fork assembly in case. Ensure mode fork shift rail is

seated in both range fork bushings.

Install output shaft and drive chain assembly. Install

mode spring on shift rail. Using bearing driver, install output shaft

rear bearing. Lubricate bearing after installation. Install seal in

oil pump feed housing. Install oil pump in housing. Tighten to

specification.

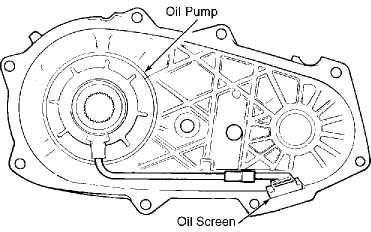

Install oil pick-up tube "O" ring in oil pump. Prime oil

pump by pouring ATF into pump through pick-up tube opening. Install

oil pump and pick-up tube in case. Ensure oil screen is properly

positioned. See Fig. 5. Install magnet in front case. Apply 1/8" bead

of silicone sealer to front case. Install rear case. Tighten to

specification. See TORQUE SPECIFICATIONS. Ensure mainshaft splines are

engaged with oil pump inner gear and a washer is used on bolts at

dowel locations.

Install rear bearings in retainer. Apply 1/8" bead of

silicone sealer and install retainer to case. Install rear retainer

snap ring. Install extension housing. Install front companion yoke.

Install NEW gasket on vacuum switch. Install vacuum switch in case.

Fill transfer case with Dexron III.

92G13082

Fig. 4: Installing Drive Sprocket Bearings Courtesy of Chrysler Corp.

Fig. 5: Identifying Oil Pump Screen Position Courtesy of Chrysler Corp.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft. Lbs. (N.m)

Companion Flange Nut

Chrysler Corp 130-200 (176-271)

General Motors 80 (108)

Jeep 110 (149)

Detent Plug

General Motors 11 (15)

Chrysler Corp. & Jeep 15 (20)

Drain & Fill Plug 30-40 (41-54)

Extension Housing Bolt 20-25 (27-34)

Front Bearing Retainer Bolt

Chrysler Corp. & Jeep 16 (22)

General Motors 14 (19)

Front Case-to-Rear Case Bolt Chrysler Corp.

Flange Head Bolt 35-45 (47-61)

All Other Bolts 20-25 (27-34)

General Motors 23 (31)

Jeep 20-25 (27-34)

Range Lever Nut 15-20 (20-27)

Rear Bearing Retainer Bolt 20-25 (27-34)

Rear Crossmember 30 (41)

Shift Lever Lock Bolt 10 (14)

Speed Sensor Bolt 23 (31)

Transfer Case-to-Transmission Nut 26 (35)

Vacuum Switch

Chrysler Corp 15-25 (20-34)

General Motors 17 (23)

Jeep 20-25 (27-34)

INCH Lbs.

Control Cable Lock Nut 18 (2)

VACUUM DIAGRAMS

For vacuum diagrams, refer to appropriate VACUUM DIAGRAMS article in the ENGINE PERFORMANCE section.