ANTI-LOCK BRAKE SYSTEM

1993 Jeep Cherokee

1993 BRAKES

Chrysler Corp. Anti-Lock - Teves

Jeep; Cherokee, Grand Cherokee, Grand Wagoneer, Wrangler DESCRIPTION

The Teves Mark IV Anti-Lock Brake System (ABS) consists of acceleration switch, Controller Anti-Lock Brake (CAB), ANTI-LOCK warning light, Hydraulic Control Unit (HCU), main relay, master cylinder, pedal travel sensor, pump motor relay, pump motor sensor, vacuum booster, 4 wheel speed sensors and axle shaft tone (pulse) rings.

During ABS operation, front wheels are controlled

individually and rear wheels are controlled together. ABS modulates brake fluid pressure during high pedal pressure and high vehicle deceleration to prevent wheel lock-up.

NOTE: For more information on brake system, see BRAKE SYSTEM article in this section.

OPERATION

The Teves Mark IV Anti-Lock Brake System (ABS) is activated during hard braking to prevent wheel lock-up. Wheel lock-up does not mean wheel has stopped, but wheel is turning slower than vehicle speed. When ignition is on, before vehicle is moved, Controller Anti-Lock Brake (CAB) performs a static system initialization. When vehicle speed reaches approximately 6 MPH, CAB briefly cycles pump to verify operation. Hydraulic Control Unit (HCU) solenoids are checked continuously.

When ABS is activated, vibrations and pulsations may be felt in brake pedal and solenoid valves clicking and pump motor running may be heard. Some wheel slip is required for best braking performance. This wheel slip may be heard as tire chirping. Do not confuse tire chirping with tire skidding. When vehicle is braked heavily, wheels will lock-up below 3 MPH. When braking on rough road surfaces, ABS may activate, detecting wheel lock-up tendencies from wheel hop.

CAUTION: See ANTI-LOCK BRAKE SAFETY PRECAUTIONS article in GENERAL INFORMATION.

BLEEDING BRAKE SYSTEM

NOTE: Use only DOT 3 brake fluid from a sealed container. DO NOT use DOT 5 silicone brake fluid.

Ensure

ignition is off. Clean master cylinder reservoir

cover and

surrounding area. Ensure reservoir is full. Bleeding

sequence is

master cylinder, Hydraulic Control Unit (HCU) valve body

(at

fluid lines), right rear wheel, left rear wheel, right front

wheel

and left front wheel.

After

bleeding master cylinder, position shop towel below

4

hydraulic control unit brakelines. Using flare

wrench, slightly open

hydraulic control unit brakeline fittings

individually.

DO NOT

allow brake fluid to contact paint or electrical

connectors.

Slowly depress brake pedal. Close hydraulic control unit

brake

pipe fitting and release brake pedal. Repeat process until no

air escapes from brake pipe fitting. Repeat procedure for remaining 3 brakelines.

4) Ensure

master cylinder reservoir is full. Raise and

support

vehicle. Bleed all 4 wheel calipers. Attach

a clear hose to

right rear caliper

bleeder valve and submerge other end of hose in

container

of brake fluid.

NOTE: DO NOT pump brake pedal while bleeding brakes. Pumping brake pedal compresses air into tiny bubbles throughout system making bleeding more difficult.

Open

bleeder valve. Slowly depress brake pedal. Close

bleeder

valve and release brake pedal. Wait 5 seconds.

Repeat process

until no air bubbles are

seen from hose. Tap lightly on

cylinder/caliper

housing to free trapped air. Close bleeder valve.

Repeat

process until no air bubbles are seen from hose. Repeat

procedure

on left rear, right front and left front bleeder valves.

Ensure

reservoir is full.

Using

DRB-II, follow prompts and perform BLEED BRAKES

procedure. After

performing BLEED BRAKES procedure using DRB-II,

repeat steps

1)-5). Ensure master cylinder reservoir is

full.

ADJUSTMENTS

REAR WHEEL SPEED SENSOR

See REAR WHEEL SPEED SENSOR under REMOVAL & INSTALLATION.

REMOVAL & INSTALLATION

ABS MAIN SYSTEM RELAY

Removal & Installation

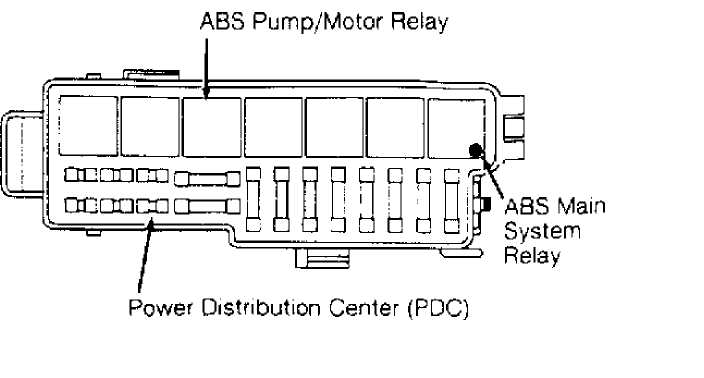

ABS main system relay is located on right side of engine compartment in Power Distribution Center (PDC). Turn ignition off. Remove cover from PDC. Locate and remove ABS main system relay from PDC. See Fig. 1. To install, reverse removal procedure.

92E22G3G

Fig. 1: Locating ABS System Relays Courtesy of Chrysler Corp.

ABS PUMP/MOTOR RELAY

Removal & Installation

ABS pump/motor relay is located on right side of engine compartment in Power Distribution Center (PDC). Turn ignition off. Remove cover from PDC. Locate and remove ABS pump/motor relay from PDC. See Fig. 1. To install, reverse removal procedure.

CONTROLLER ANTI-LOCK BRAKE (CAB)

Removal & Installation (Cherokee)

Turn ignition off. CAB is located under instrument panel to right of steering column. Remove screws attaching CAB mounting bracket to vehicle. Disconnect CAB electrical connector. Disconnect security alarm module electrical connector. Security alarm module is mounted on opposite side of mounting bracket. Remove CAB and mounting bracket. See Fig. 2. To install, reverse removal procedure. If installing a new CAB, transfer mounting bracket to new CAB.

Fig. 2: Locating Controller Anti-Lock Brake (CAB) Courtesy of Chrysler Corp.

CAUTION: DO NOT force CAB electrical connector onto CAB. CAB pins are easily damaged.

Removal & Installation (Grand Cherokee & Grand Wagoneer) Turn ignition off. Disconnect negative battery cable. CAB is located on driver-side inner fender panel. Remove screws attaching CAB to fender panel bracket. Remove CAB from bracket for access to CAB electrical connector. Release strap securing harness connector to CAB. Tilt CAB electrical connector upward to disengage. Slide CAB electrical connector from retaining tangs. Remove CAB from vehicle. To install, reverse removal procedure.

Removal & Installation (Wrangler)

Turn

ignition off. Disconnect negative battery cable. CAB

is located

above heater/air conditioning plenum housing in line with

the

glove box. Remove bolts and nuts securing CAB to dash panel.

Bolts

and nuts are accessible from the engine compartment and are

located to

the right of the battery.

On models

with air conditioning, remove air conditioning

fascia panel and

ducts to access CAB harness connector. Release strap

securing

harness connector to CAB. Tilt CAB electrical connector

outward

to disengage. Slide CAB electrical connector from retaining

tangs.

Remove CAB from vehicle. To install, reverse removal procedure.

FRONT WHEEL SPEED SENSOR

Removal & Installation

Turn

ignition off. Raise and support vehicle. Remove wheel

and tire

assembly. Clean area surrounding wheel speed sensor prior

to

removal. Remove bolt attaching wheel speed sensor to steering

knuckle.

Unseat

grommet retaining wheel speed sensor wire in wheel

well panel.

Disconnect wheel speed sensor electrical connector in

engine

compartment. Disconnect wheel speed sensor wire harness from

clips

on body, chassis, and steering knuckle. Remove wheel speed

sensor

from vehicle.

To

install, reverse removal procedure. Remove all kinks

and twists

from wheel speed sensor wire harness. Ensure wheel speed

sensor

wire harness is installed in clips on body, chassis and

steering

knuckle. Use Loctite on wheel speed sensor mounting bolt.

Tighten

wheel speed sensor bolt to specification. See

TORQUE

SPECIFICATIONS table. Air gap is not adjustable. Air gap should

be

.040" (1.3 mm). If

air gap is not to specification, replacement of

wheel speed

sensor and/or tone wheel may be necessary.

"G" SWITCH

Removal & Installation (Except Wrangler)

Turn ignition off. Disconnect negative battery cable. Tilt rear seat assembly forward to access "G" switch. Disconnect "G" switch electrical connector. Remove "G" switch mounting bolts. Remove "G" switch. See Fig. 3. To install, reverse removal procedure. Ensure arrow on top of "G" switch is facing toward front of vehicle.

Fig. 3: Locating "G" Switch (Typical Except Wrangler) Courtesy of Chrysler Corp.

Removal & Installation (Wrangler)

Turn ignition off. Disconnect negative battery cable. Move driver’s seat assembly forward or rearward to access "G" switch. Disconnect "G" switch electrical connector. Remove "G" switch mounting bracket-to-floorpan screws. Remove "G" switch from mounting bracket. See Fig. 4. To install, reverse removal procedure. Ensure arrow on top of "G" switch is facing toward front of vehicle.

CCD Connector

"G- Switch

ition

Fig. 4: Locating "G" Switch & CCD Connector (Wrangler) Courtesy of Chrysler Corp.

HYDRAULIC CONTROL UNIT (HCU)

Removal & Installation

Turn

ignition off. Disconnect negative battery cable.

Disconnect pedal

travel sensor electrical connector. Remove air

cleaner and hoses.

On Grand Cherokee and Grand Wagoneer,

remove

windshield washer reservoir. On all models, position a

small drain

container under master cylinder reservoir hoses.

Disconnect master

cylinder reservoir

hoses at HCU and drain fluid into container. See

Fig.

5. Discard fluid. Disconnect HCU

electrical connectors.

On

Grand Cherokee and Grand Wagoneer, remove combination

valve. On

all models, identify HCU brakelines for reassembly

reference.

Disconnect brakelines from HCU. Remove bolt and nuts

attaching

HCU mounting bracket to inner fender panel. Remove

HCU from

vehicle. To install, reverse

removal procedure. Bleed brake system.

See

BLEEDING BRAKE SYSTEM.

Fig. 5: Locating Hydraulic Control Unit (HCU) Courtesy of Chrysler Corp.

PEDAL TRAVEL SENSOR

Removal & Installation

Turn ignition off. Disconnect pedal travel sensor electrical connector. Pump brake pedal to exhaust all vacuum from vacuum booster. Unseat pedal travel sensor retaining ring. Remove pedal travel sensor from vacuum booster. See Fig. 6. To install, reverse removal procedure. Ensure color dot on face of vacuum booster matches color of plunger tip. If colors are different, replace plunger tip to match color dot on vacuum booster.

Fig. 6: Locating Pedal Travel Sensor Courtesy of Chrysler Corp.

REAR WHEEL SPEED SENSOR

Removal

Turn

ignition off. Raise and fold rear seat to access rear

wheel speed

sensor connectors. Disconnect rear wheel speed sensor

electrical

connector. Push rear wheel speed sensor grommet and wire

harness

through floorpan on vehicle.

Raise and

support vehicle. Remove wheel and brake drum.

Remove clips

attaching rear wheel speed sensor wire harness to

brakelines.

Unseat rear wheel speed sensor grommet from brake backing

plate.

Remove rear wheel speed sensor mounting bolt. Push rear wheel

speed

sensor through grommet opening in backing plate. Remove rear

wheel

speed sensor from vehicle.

Installation

If

original wheel speed sensor is being installed, go to

step

3). If a NEW wheel speed sensor is being

installed, position

wheel speed sensor until cardboard spacer

contacts tone wheel.

Use

Loctite on the wheel speed sensor mounting bolt.

Tighten wheel

speed sensor mounting bolt to specification. Refer to

TORQUE SPECIFICATIONS. Spin rear axle by hand until cardboard spacer is peeled from sensor face. Air gap adjustment should be correct. Using a brass feeler gauge, check air gap adjustment. Air gap should be .043" (1.1 mm). If air gap is not correct, adjust as necessary. Go to step 4).

Remove

any remaining pieces of cardboard from sensor face.

Install

wheel speed sensor. Using a brass feeler gauge, adjust air

gap.

Air gap should be .043" (1.1 mm).

Use Loctite on wheel speed

sensor mounting

bolt. Tighten wheel speed sensor mounting bolt to

specification.

See TORQUE SPECIFICATIONS.

Remove

all kinks and twists from wheel speed sensor wire

harness.

Ensure wheel speed sensor wire harness is installed in clips

on

brakelines. To complete installation,

reverse removal procedure.

DIAGNOSIS & TESTING

NOTE: DRB-II and appropriate cartridge are necessary for

diagnosing ABS.

WARNING LIGHTS

Amber ABS Warning Light

After engine start-up, ABS warning light glows as part of a self-check feature. ABS warning light normally will light for 2-3 seconds and then go out. If ABS warning light remains illuminated after engine start-up, diagnosis will be necessary to determine which component or circuit is malfunctioning.

Red BRAKE Warning Light

With ignition on, Red BRAKE warning light will glow when low brake fluid level is detected or parking brake switch is closed. BRAKE warning light normally indicates a hydraulic or mechanical failure is present.

PRE-DIAGNOSTIC INSPECTION

Check

master cylinder reservoir for correct fluid level.

Inspect

Hydraulic Control Unit (HCU) for leakage and wiring damage.

Check

caliper piston for activation and release. Check all brakes

to

verify no drag exists.

Check

speed sensors for correct mounting and alignment.

Inspect wire

harness for correct routing. Ensure connectors are not

damaged

and have good contact.

Verify

all wheel bearings are not worn or causing wheel

wobble.

Ensure all tires are in good condition and properly inflated.

After

performing pre-diagnostic inspection, perform TEST-1A

under

SELF-DIAGNOSTIC TESTS using

DRB-II. See Figs. 4, 7 and 8.

T

T

CCD Connector Location

92B22G41

Fig. 7: Locating CCD Connector (Cherokee) Courtesy of Chrysler Corp.

Fig. 8: Locating CCD Connector (Grand Cherokee & Grand Wagoneer) Courtesy of Chrysler Corp.

INTERMITTENTS

Most intermittent problems are caused by faulty electrical

connections

or wiring; however, a sticking relay or solenoid can cause

a

failure.

When intermittent failure is encountered, check for fault

messages stored in CAB. If fault messages are found, inspect related

components

and circuitry for poor connections. If no trouble codes are

found,

inspect suspect circuits as follows:

Check

for poor mating of connector halves, or terminals not

fully

seated in connector body (backed-out).

Check for

improperly formed or damaged terminals. Carefully

reform all

connector terminals of problem circuit to increase

contact

tension.

Check for poor terminal-to-wire connection.

Check for hydraulic system leaks.

CLEARING FAULT MESSAGES

DRB-II

Using DRB-II, select ADJUSTMENTS. Press "1" (ERASE FAULTS key). Press ENTER key. DRB-II will display ERASE FAULTS ARE YOU SURE? (ENTER TO ERASE). Press ENTER key. DRB-II will display ERASE FAULTS TURN KEY OFF. Turn ignition off. Turn ignition on. DRB-II will display

ERASE FAULTS FAULTS ERASED. Faults are now erased.

Ignition Cycle Default

If no fault codes occur for 50 driving cycles, any existing fault messages will be cleared from CAB memory. A drive cycle occurs when ignition is turned on and vehicle is driven faster than 10 MPH.

CONNECTOR IDENTIFICATION

CONNECTOR IDENTIFICATION DIRECTORY TABLE

Connector

Figure

ABS Disconnect Connector 9

ABS Main System Relay Socket Connector 10

ABS Pump/Motor Relay Socket Connector 11

Controller Anti-Lock Brake (CAB) Connector 12

"G" Switch Connector 13

Hydraulic Control Unit (HCU) Connector 14

Pump/Motor Connector 15

Fig. 9: Identifying ABS Disconnect Connector Terminals Courtesy of Chrysler Corp.

Fig. 10: Identifying ABS Main System Relay Connector Terminals Courtesy of Chrysler Corp.

92F22G45

Fig. 11: Identifying ABS Pump/Motor Relay Connector Terminals Courtesy of Chrysler Corp.

92G22G4G

Fig. 12: Controller Anti-Lock Brake (CAB) Connector Terminal ID Courtesy of Chrysler Corp.

Fig. 13: Identifying "G" Switch Connector Terminals Courtesy of Chrysler Corp.

92

122648

92

122648

Fig. 14: Hydraulic Control Unit (HCU) Connector Terminal ID Courtesy of Chrysler Corp.

92J22G49

Fig. 15: Identifying Pump/Motor Connector Terminals Courtesy of Chrysler Corp.

SELF-DIAGNOSTIC TESTS

NOTE: Connector and terminal identification illustrations in following tests are provided courtesy of Chrysler Corp.

NOTE: For connector terminal identification in following tests,

see CONNECTOR IDENTIFICATION under DIAGNOSIS & TESTING. For wire color and terminal identification, see WIRING DIAGRAMS.

TEST 1A

READING FAULT MESSAGES

Using DRB-II, read fault messages and perform appropriate test listed in FAULT MESSAGES table. If DRB-II displays NO RESPONSE message, perform TEST 23A. If other DRB-II related communication problems exist, see VEHICLE COMMUNICATIONS article in ENGINE PERFORMANCE. If multiple fault messages are present, fault repairs must be performed in order in which they are displayed. If no fault messages are present, perform VERIFICATION TEST VER-1A.

FAULT MESSAGES TABLE

Fault Message Perform Test

CONTROLLER FAILURE 2A

"G" SWITCH NOT PROCESSABLE 3A

HYDRAULIC FAILURE 4A

LEFT FRONT INLET VALVE 5A

LEFT FRONT OUTLET VALVE 6A

LEFT FRONT SENSOR CIRCUIT FAILURE 7A

LEFT FRONT SENSOR CONTINUITYK25 MPH 7A

LEFT FRONT SENSOR CONTINUITYJ25 MPH 7A

LEFT FRONT SENSOR SIGNAL MISSING 7A

LEFT FRONT WHEEL SPEED COMPARISON 7A

REAR INLET VALVE 9A

REAR OUTLET VALVE 10A

LEFT REAR SENSOR CIRCUIT FAILURE 11A

LEFT REAR SENSOR CONTINUITYK25 MPH 11A

LEFT REAR SENSOR CONTINUITYJ25 MPH 11A

LEFT REAR SENSOR SIGNAL MISSING 11A

LEFT REAR WHEEL SPEED COMPARISON 11A

MAIN RELAY/POWER CIRCUIT FAILURE 13A

PEDAL TRAVEL SENSOR CIRCUIT 14A

PUMP MOTOR CIRCUIT NOT WORKING PROPERLY 15A

RIGHT FRONT INLET VALVE 16A

RIGHT FRONT OUTLET VALVE 17A

RIGHT FRONT CIRCUIT FAILURE 18A

RIGHT FRONT SENSOR CONTINUITYK25 MPH 18A

RIGHT FRONT SENSOR CONTINUITYJ25 MPH 18A

RIGHT FRONT REAR SENSOR SIGNAL MISSING 18A

RIGHT FRONT WHEEL SPEED COMPARISON 18A

RIGHT REAR SENSOR CIRCUIT FAILURE 20A

RIGHT REAR SENSOR CONTINUITYK25 MPH 20A

RIGHT REAR SENSOR CONTINUITYJ25 MPH 20A

RIGHT REAR SENSOR SIGNAL MISSING 20A

RIGHT REAR WHEEL SPEED COMPARISON 2 0A

ABS WARNING LAMP ILLUMINATION PROBLEM 22A

NO RESPONSE 23A

TEST 2A

CONTROLLER FAILURE

If DRB-II displays CONTROLLER FAILURE, replace Controller Anti-Lock Brake (CAB). Perform VERIFICATION TEST VER-1A.

TEST 3A

"G" SWITCH NOT PROCESSABLE

Ensure "G"

switch sensor assembly is properly installed.

If not properly

installed, repair as necessary and perform

VERIFICATION TEST

VER-1A. If "G" switch is properly installed, turn

ignition

off. Disconnect and inspect CAB 55-pin connector and "G"

switch

sensor 3-pin connector. Repair connectors as necessary.

Turn

ignition on. With DRB-II in voltmeter mode, probe "G"

switch

connector terminals individually. If voltage is present,

repair

short to voltage in that "G" switch circuit.

Perform VERIFICATION TEST

VER-1A. If voltage is not present at

any terminals, go to next step.

Turn

ignition off. With DRB-II in ohmmeter mode, probe "G"

switch

connector terminals individually with remaining lead connected

to

chassis ground. If resistance at any terminal is less than 5

ohms,

repair short

to ground in that circuit. Perform VERIFICATION TEST VER-

1A.

If

resistance at each terminal is more than 5 ohms,

connect

jumper wire between ground and "G" switch terminals No.

1-3.

Check for continuity to ground on

CAB terminals No. 25, 26 and 43.

If

continuity to

ground does not exist, repair open in that circuit.

Perform

VERIFICATION TEST VER-1A. If continuity to ground exists,

replace

CAB. Perform VERIFICATION TEST VER-1A.

TEST 4A

HYDRAULIC FAILURE

Inspect

brake system for hydraulic leaks, and repair as

necessary. If

brake system is okay, using DRB-II, read fault messages.

If

DRB-II displays PUMP/MOTOR NOT WORKING PROPERLY, perform TEST

15A.

If DRB-II displays PEDAL TRAVEL SENSOR CIRCUIT, perform TEST

14A. If

DRB-II does not display PUMP/MOTOR NOT WORKING PROPERLY

or PEDAL

TRAVEL SENSOR CIRCUIT, using DRB-II, erase fault

messages.

Using

DRB-II, monitor read faults display for 4 minutes.

If

any fault messages are displayed, perform TEST 1A. If no

fault

messages are displayed, depress brake pedal and hold down

until

instructed to release it. Using

DRB-II, actuate hydraulic valve test.

Release

brake pedal.

If

brake pedal came back up, perform TEST 14A. If brake

pedal

dropped all the way to the floor or there were not 3

slight

drops in the brake pedal, perform TEST

4B. If the brake pedal did not

come

back up at end of test, replace pump/motor assembly. If the

brake

pedal did come back up at end of test, replace CAB. If CAB

has already

been replaced, replace HCU.

Perform VERIFICATION TEST VER-1A.

TEST 4B

HYDRAULIC FAILURE

Disconnect and inspect CAB 55-pin connector. Repair connector as necessary. Disconnect and inspect hydraulic unit 10-pin connector. Repair connector as necessary. If terminals of both connectors are not

pushed out, damaged or improperly wired, replace hydraulic control unit. Perform VERIFICATION TEST VER-1A.

TEST 5A

LEFT FRONT INLET VALVE

Disconnect

and inspect hydraulic unit 10-pin connector.

Repair connector as

necessary. Turn ignition on. With DRB-II in

voltmeter mode, probe

terminal No. 4 (White/Light Green wire)

of

hydraulic unit connector. If voltage is present, repair short

to

voltage in White/Light Green wire.

Perform VERIFICATION TEST VER-1A.

If

voltage is not present, turn ignition off. Disconnect

and inspect

CAB 55-pin connector. Repair connector as necessary. With

DRB-II

in ohmmeter mode, probe terminal No. 4 (White/Light

Green wire)

of hydraulic unit connector. If resistance is less

than 5 ohms, repair

short to ground in

White/Light Green wire.

If

resistance is more than 5 ohms, check

resistance of

White/Light Green wire

between terminals No. 20 of CAB connector

and

No. 4 of

hydraulic unit connector using an external ohmmeter. If

resistance

is more than 5 ohms, repair open in

White/Light Green wire.

Perform VERIFICATION TEST VER-1A.

If

resistance is less than 5 ohms, measure

resistance of

left front inlet valve.

If resistance is 5-8 ohms, replace

CAB.

Perform VERIFICATION TEST VER-1A. If resistance is not 5-8

ohms,

replace hydraulic control unit. Perform

VERIFICATION TEST VER-1A.

TEST 6A

LEFT FRONT OUTLET VALVE

Disconnect

and inspect hydraulic unit 10-pin connector.

Repair

connector as necessary. Turn ignition on. With DRB-II in

voltmeter

mode, probe terminal No. 9 (Dark

Green/Black wire) of

hydraulic unit connector. If voltage is

present, repair short to

voltage in

Dark Green/Black wire. Perform VERIFICATION TEST VER-1A.

If

voltage is not present, turn ignition off. Disconnect

and inspect

CAB 55-pin connector. Repair connector as necessary. With

DRB-II

in ohmmeter mode, probe terminal No. 9 (Dark

Green/Black wire)

of hydraulic unit

connector. If resistance is less than 5 ohms,

repair

short to ground in Dark Green/Black wire.

If

resistance is more than 5 ohms, check

resistance of

Dark Green/Black wire

between terminals No. 2 of CAB connector

and No.

9 of hydraulic unit connector

using an external ohmmeter. If

resistance is more than 5

ohms, repair open in Dark Green/Black

wire.

Perform VERIFICATION TEST VER-1A.

If

resistance is less than 5 ohms, measure

resistance of

left front outlet valve. If resistance is not 3-5

ohms, replace

hydraulic control unit. Perform

VERIFICATION TEST VER-1A. If

resistance

is 3-5 ohms, replace CAB. Perform

VERIFICATION TEST VER-1A.

TEST 7A

LEFT FRONT SENSOR CIRCUIT FAILURE

1) Using DRB-II, read and record all speed sensor fault messages. If DRB-II does not display LEFT FRONT SENSOR CIRCUIT FAILURE, perform TEST 8A. If DRB-II displays LEFT FRONT SENSOR CIRCUIT FAILURE, inspect left front wheel speed sensor for damage. If sensor is damaged, repair or replace sensor as necessary. Perform

VERIFICATION TEST VER-1A. If sensor is okay, turn ignition off.

Disconnect

and inspect CAB 55-pin connector. Repair

connector as necessary.

Turn ignition on. With DRB-II in voltmeter

mode,

probe terminal No. 48 (Red wire) of CAB

connector. If voltage is

present,

repair short to battery in Red wire. Perform VERIFICATION

TEST

VER-1A.

If

voltage is not present, turn ignition off. With DRB-II

in

ohmmeter mode, probe terminal No. 48 (Red

wire) of CAB connector.

If resistance

is less than 5 ohms, repair short to

ground in Red wire.

Perform

VERIFICATION TEST VER-1A. If resistance is more than 5

ohms,

go to next

step.

Using

an external ohmmeter, check resistance between

terminal

No. 48 (Red wire) and No. 30

(Red/Dark Blue wire) of CAB

connector.

If resistance is 900-1300 ohms, replace

CAB. Perform

VERIFICATION TEST VER-1A. If resistance is not

900-1300 ohms,

disconnect and inspect

left front wheel speed sensor connector.

Using

an external ohmmeter, check resistance between left

wheel speed

sensor connector terminals. If resistance is not 900-1300

ohms,

replace wheel speed sensor. Perform VERIFICATION TEST VER-1A.

If

resistance is 900-1300 ohms,

check resistance of Red wire between

terminal No. 48 of

CAB connector and No. 1 of left front

wheel speed

sensor connector using an

external ohmmeter.

If

resistance is more than 5 ohms, repair

open Red wire.

Perform VERIFICATION TEST VER-1A. If resistance is

less than 5 ohms,

repair

open Red/Dark Blue wire. Perform VERIFICATION TEST VER-1A.

TEST 8A

LEFT FRONT SENSOR

Inspect

left front wheel speed sensor for damage. Repair

or replace

sensor as necessary. Perform VERIFICATION TEST VER-1A. If

sensor

is okay, check left front sensor tone (pulse) ring for

damage.

Repair or replace tone ring as necessary. Perform

VERIFICATION TEST

VER-1A. If tone ring is okay, inspect left

front wheel speed sensor

wiring harness for damage.

Repair or replace wiring as necessary. Perform

VERIFICATION TEST VER-1A. If wiring harness is okay, disconnect and inspect left front wheel speed sensor connector. Repair connector as necessary. Using an external ohmmeter, check resistance between left front wheel speed sensor connector terminals.

3) If

resistance is not 900-1300 ohms, replace

wheel speed

sensor. Perform VERIFICATION TEST VER-1A. If

resistance is 900-1300

ohms, replace

CAB. Perform VERIFICATION TEST VER-1A.

NOTE: If excessive axle deflection occurs on extremely bumpy

surfaces or during off road use, it is possible for a wheel speed sensor to set a code.

TEST 9A

REAR INLET VALVE

Disconnect

and inspect hydraulic unit 10-pin connector.

Repair connector as

necessary. Turn ignition on. With DRB-II in

voltmeter mode, probe

terminal No. 4 (White/Black wire on

Cherokee and

Wrangler or White/Red wire on Grand Cherokee and

Grand Wagoneer) of

hydraulic unit connector. If voltage is

present, repair short to

voltage in White/Black or White/Red

wire. Perform VERIFICATION TEST

VER-1A.

If voltage is not present, turn ignition off. Disconnect

and inspect CAB 55-pin connector. Repair connector as necessary. With DRB-II in ohmmeter mode, probe terminal No. 4 of hydraulic unit connector. If resistance is less than 5 ohms, repair short to ground in White/Black or White/Red wire. Perform VERIFICATION TEST VER-1A.

If

resistance is less than 5 ohms, check

resistance of

between terminal No. 54

of CAB connector and No. 4 of

hydraulic unit

connector using an

external ohmmeter. If resistance is more than 5

ohms,

repair open in White/Black or White/Red wire. Perform

VERIFICATION

TEST VER-1A.

Using

an external ohmmeter, check resistance between

terminals

No. 4 and 5 of

hydraulic control unit pigtail connector. If

resistance

is not 5-8 ohms, replace hydraulic control

unit. Perform

VERIFICATION TEST VER-1A.

If resistance is 5-8 ohms, replace

CAB.

Perform VERIFICATION TEST VER-1A.

TEST10A

REAR OUTLET VALVE

Disconnect

and inspect hydraulic unit 10-pin connector.

Repair

connector as necessary. Turn ignition on. With DRB-II in

voltmeter

mode, probe terminal No. 7 (Dark

Green/Orange wire) of

hydraulic unit connector. If voltage is

present, repair short to

voltage in

Dark Green/Orange wire. Perform VERIFICATION TEST VER-1A.

If

voltage is not present, turn ignition off. Disconnect

and

inspect CAB 55-pin connector. Repair connector as necessary.

With

DRB-II in ohmmeter mode, probe

terminal No. 7 (Dark Green/Orange wire)

of

hydraulic unit connector. If resistance is less than 5 ohms,

repair

short to ground in Dark Green/Orange wire.

If

resistance is more than 5 ohms, check

resistance of

Dark Green/Orange wire between terminal No. 36

of CAB connector and

No. 7 of

hydraulic unit connector using an external ohmmeter. If

resistance

is more than 5 ohms, repair open Dark

Green/Orange wire.

Perform VERIFICATION

TEST VER-1A. If resistance is less than 5 ohms,

go

to next step.

Using

an external ohmmeter, check resistance between

terminals No. 7

and 10 of hydraulic

control unit connector. If

resistance

is not 3-5 ohms, replace hydraulic control

unit. Perform

VERIFICATION TEST VER-1A. If resistance is 3-5

ohms, replace CAB.

Perform

VERIFICATION TEST VER-1A.

TEST 11A

LEFT REAR SENSOR CIRCUIT FAILURE

1) Using DRB-II, read and record all speed sensor fault

messages. If DRB-II does not display LEFT REAR SENSOR CIRCUIT FAILURE, perform TEST 12A. If DRB-II displays LEFT REAR SENSOR CIRCUIT FAILURE, inspect left rear wheel speed sensor for damage. If sensor is damaged, repair or replace sensor as necessary. Perform VERIFICATION TEST VER-1A. If sensor is okay, turn ignition off.

Disconnect

and inspect CAB 55-pin connector. Repair

connector as necessary.

Turn ignition on. With DRB-II in voltmeter

mode,

probe terminal No. 46 (Light Green wire)

of CAB connector. If

voltage is present, perform TEST 11B.

If

voltage is not present, turn ignition off. With DRB-II

in

ohmmeter mode, probe terminal No. 46 (Light

Green wire) of CAB

connector. If resistance is less than 5

ohms, perform TEST 11C. If

resistance is more

than 5 ohms, using an external ohmmeter,

check

resistance between terminal No.

46 (Light Green wire) and No. 28

(Light

Green/Dark Blue wire) of CAB connector.

If

resistance is 900-1300 ohms, replace CAB.

Perform

VERIFICATION TEST VER-1A. If

resistance is not 900-1300 ohms,

disconnect

and inspect left rear wheel speed sensor connector. Using

an

external ohmmeter, check resistance between left rear wheel

speed

sensor connector terminals. If resistance is not 900-1300

ohms,

replace wheel speed sensor. Perform

VERIFICATION TEST VER-1A.

If

resistance is 900-1300 ohms, connect a

jumper wire

between terminal No. 46

(Light Green wire) of CAB connector and

ground.

With DRB-II in ohmmeter mode, probe Light Green wire of left

rear

wheel speed sensor connector. If resistance is more than 5

ohms,

perform TEST

11D. If resistance is less than 5 ohms,

perform TEST 11E.

TEST11B

LEFT REAR SENSOR CIRCUIT FAILURE

On

Cherokee and Wrangler, repair short to battery voltage

in Light

Green wire. Perform VERIFICATION TEST VER-1A. On Grand

Cherokee

and Grand Wagoneer, disconnect and inspect Black ABS

8-pin

disconnect connector. Connector is located behind left side

kick

panel. Repair connector as necessary. With DRB-II in

voltmeter mode,

probe Light Green wire of ABS disconnect

connector.

If voltage

is not present, repair short to battery voltage

in Light Green

wire between wheel speed sensor and CAB disconnect

connector.

Perform VERIFICATION TEST VER-1A. If voltage is present,

repair

short to battery voltage in Light Green wire between ABS

disconnect

connector and CAB 55-pin connector. Perform VERIFICATION

TEST

VER-1A.

TEST 11C

LEFT REAR SENSOR CIRCUIT FAILURE

On

Cherokee and Wrangler, repair short to ground in Light

Green

wire. Perform VERIFICATION TEST VER-1A. On Grand Cherokee and

Grand

Wagoneer, disconnect and inspect Black CAB 8-pin

disconnect

connector. Connector is located behind left side kick

panel. Repair

connector as necessary. With DRB-II in ohmmeter

mode, probe Light

Green wire of ABS disconnect connector.

If

resistance is more than 5 ohms, repair

short to ground

in Light Green wire between wheel speed sensor

and ABS disconnect

connector. Perform

VERIFICATION TEST VER-1A. If resistance is less

than 5

ohms, repair short to ground in Light Green wire

between ABS

disconnect connector and CAB 55-pin connector.

Perform VERIFICATION

TEST VER-1A.

TEST11D

LEFT REAR SENSOR CIRCUIT FAILURE

On

Cherokee and Wrangler, repair open in Light Green wire.

Perform

VERIFICATION TEST VER-1A. On Grand Cherokee and Grand

Wagoneer,

disconnect and inspect Black CAB 8-pin disconnect

connector.

Connector is located behind left side kick panel.

Repair connector as

necessary. With DRB-II in ohmmeter mode,

probe Light Green wire of ABS

disconnect connector.

If

resistance is less than 5 ohms, repair

open in Light

Green wire between wheel speed sensor and ABS

disconnect connector.

Perform VERIFICATION TEST VER-1A. If

resistance is more than 5 ohms,

repair

open in Light Green wire between ABS disconnect connector and

CAB 55-pin connector. Perform VERIFICATION TEST VER-1A.

TEST11E

LEFT REAR SENSOR CIRCUIT FAILURE

On

Cherokee and Wrangler, repair open in Light Green/Dark

Blue

wire. Perform VERIFICATION TEST VER-1A. On Grand Cherokee and

Grand

Wagoneer, disconnect and inspect Black ABS 8-pin

disconnect

connector. Connector is located behind left side kick

panel. Repair

connector as necessary.

Connect a jumper wire between terminal No. 28

(Light

Green/Dark Blue wire) of CAB connector and ground. With DRB-II

in

ohmmeter mode, probe Light Green/Dark Blue wire of ABS

disconnect

connector.

If

resistance is less than 5 ohms, repair

open in Light

Green/Dark Blue wire

between wheel speed sensor and ABS disconnect

connector. Perform

VERIFICATION TEST VER-1A. If resistance is more

than 5

ohms, repair open in Light Green/Dark Blue wire

between ABS

disconnect connector and

CAB 55-pin connector. Perform VERIFICATION

TEST

VER-1A.

TEST12A

LEFT REAR SENSOR

Inspect

left rear wheel speed sensor. If speed sensor is

damaged,

contaminated or loose, repair or replace speed sensor as

necessary.

Perform VERIFICATION TEST VER-1A. If speed sensor is okay,

inspect

left rear tone (pulse) ring for damaged teeth or excessive

runout.

Runout should not exceed .003" (.08 mm).

Repair or replace

tone ring as necessary.

Perform VERIFICATION TEST VER-1A.

If

tone ring is okay, using a feeler gauge, check left

rear wheel

sensor-to-tone ring clearance. If clearance is not .036-.

050"

(.91-1.27 mm), repair as necessary. If clearance

is .036-.050" (.

91-1.27 mm),

inspect left rear wheel speed sensor inspect left front

wheel

speed sensor wiring harness for damage.

Repair

or replace wiring as necessary. If wiring harness

is okay,

disconnect and inspect left rear wheel speed sensor

connector.

Repair connector as necessary. Using an external ohmmeter,

check

resistance between left rear wheel speed sensor connector

terminals.

If

resistance is not 900-1300 ohms, replace

wheel speed

sensor. Perform VERIFICATION TEST VER-1A. If

resistance is 900-1300

ohms, replace

CAB. Perform VERIFICATION TEST VER-1A.

NOTE: If excessive axle deflection occurs on extremely bumpy

surfaces or during off road use, it is possible for a wheel speed sensor to set a code.

TEST 13A

MAIN RELAY/POWER CIRCUIT FAILURE

Check

ABS system fuse in Power Distribution Center (PDC).

If

fuse is not okay, perform TEST 13B. If fuse is okay, go to

next

step.

Check if

charging system is overcharging. If charging

system is operating

properly, go to next step. If charging system is

not operating

properly, repair as necessary. Perform VERIFICATION TEST

VER-1A.

Temporarily

replace ABS main relay with another 5-terminal

relay from PDC.

Using DRB-II, erase ABS fault messages. Cycle ignition

off and

on. Using DRB-II, read ABS fault messages. If MAIN

RELAY/POWER

CIRCUIT FAILURE message is displayed, go to next

step. If fault is not

displayed, replace ABS main relay. Perform

VERIFICATION TEST VER-1A.

Install

replacement 5-terminal relay back into PDC,

leaving

ABS main relay disconnected (removed). With

DRB-II in

voltmeter mode, probe fused battery feed Red/Dark Green

wire

(Red/Light Green wire on Grand Cherokee and Grand Wagoneer) at ABS main relay socket. If voltage is more than 9 volts, go to next step. If voltage is less than 9 volts, repair open Red/Dark Green wire

(Red/Light Green on Grand Cherokee and Grand Wagoneer) wire to ABS fuse in PDC. Perform VERIFICATION TEST VER-1A.

Turn

ignition off. Disconnect and inspect CAB 55-pin

connector. Repair

connector as necessary. Ensure ABS main relay is

still

disconnected. Using an external ohmmeter, check continuity of

Pink

(Pink/Dark Blue on Grand Cherokee and Grand Wagoneer) wire

between

CAB connector terminal No. 34 and ABS main

relay socket

terminal "C". If

resistance is less than 5 ohms, go to next

step. If

resistance is more than 5

ohms, repair open Pink (Pink/Dark Blue on

Grand

Cherokee and Grand Wagoneer) wire to ABS main relay.

Perform

VERIFICATION TEST VER-1A.

Check

continuity of Gray/Yellow wire between CAB connector

terminal

No. 3 and ABS main relay socket terminal

"B". If resistance

is less

than 5 ohms, go to next step. If

resistance is more than 5

ohms, repair

open Gray/Yellow wire to ABS main relay. Perform

VERIFICATION

TEST VER-1A.

Check

continuity of Gray/Yellow wire between CAB connector

terminal

No. 33 and ABS main relay socket terminal

"B". If resistance

is

less than 5 ohms, replace CAB. Perform

VERIFICATION TEST VER-1A. If

resistance

is more than 5 ohms, repair open

Gray/Yellow wire to ABS

main relay.

Perform VERIFICATION TEST VER-1A.

TEST13B

MAIN RELAY/POWER CIRCUIT FAILURE

Remove

ABS system fuse from Power Distribution Center

(PDC).

Remove ABS main relay from PDC, and inspect

connector. Repair

connector as

necessary. With DRB-II in ohmmeter mode, probe fused

battery feed

Red/Dark Green wire (Red/Light Green wire on Grand

Cherokee

and Grand Wagoneer or Red/Dark Blue wire on Wrangler) at ABS

main

relay socket. If resistance is less than 5 ohms,

repair Red/Dark

Green wire (Red/Light Green wire on Grand

Cherokee and Grand Wagoneer

or Red/Dark

Blue wire on Wrangler) for a short to ground. Perform

VERIFICATION

TEST VER-1A. If resistance is more than 5 ohms,

go to

next step.

Remove ABS pump/motor relay from PDC, and inspect

connector. Repair connector as necessary. Using an external ohmmeter, measure resistance of ABS pump/motor relay coil. See Fig. 16. If resistance is 35-65 ohms, go to next step. If resistance is not 35-65 ohms, replace ABS pump/motor relay. Perform VERIFICATION TEST VER-1A.

3) Disconnect

hydraulic control unit 10-pin connector. With

DRB-II

in ohmmeter mode, probe Gray/Yellow wire (Gray/Pink wire on

Grand

Cherokee and Grand Wagoneer) at ABS main relay socket terminal

"B".

If resistance is less than 5 ohms,

repair Gray/Yellow wire

(Gray/Pink wire

on Grand Cherokee and Grand Wagoneer) for a short to

ground. Perform VERIFICATION TEST VER-1A. If resistance is more than 5 ohms, go to next step.

4) Reconnect

all disconnected components. Install a new ABS

fuse

in PDC and cycle ignition off and on. Inspect ABS fuse in PDC.

If

fuse is okay (does not blow), perform

TEST 13C. If fuse is not okay

(blows), replace hydraulic control unit. Perform VERIFICATION TEST VER-1A.

Fig. 16: Measuring ABS Pump/Motor Relay Resistance

TEST13C

MAIN RELAY/POWER CIRCUIT FAILURE

Ensure

DRB-II is NOT in TEVES ABS DIAGNOSTIC MODE. Road

test vehicle,

making several ABS stops. Inspect ABS fuse in PDC. If

fuse

is okay (does not blow), ABS system is

operating properly at this

time. Perform VERIFICATION TEST

VER-1A.

If fuse is

not okay (blows), inspect ABS wiring harness

for damage and

repair as necessary. Perform VERIFICATION TEST VER-1A.

If wiring

harness is okay, replace hydraulic control unit.

Perform

VERIFICATION TEST VER-1A.

TEST14A

PEDAL TRAVEL SENSOR CIRCUIT

Inspect

pedal travel sensor connector. Sensor is located

on right side of

brake booster. If connector is disconnected and/or

damaged,

repair connector as necessary and perform VERIFICATION TEST

VER-1A.

If connector is properly connected and NOT damaged, go to next

step.

Turn

ignition off. Disconnect and inspect CAB 55-pin

connector. Repair

connector as necessary. Turn ignition on. Disconnect

and inspect

pedal travel sensor connector. Repair connector as

necessary.

With DRB-II in voltmeter mode, probe Gray/Light Blue wire

at

sensor connector. If no voltage is present, go to next step.

If

voltage is present, repair Gray/Light Blue wire for a short to

battery

voltage. Perform VERIFICATION TEST VER-1A.

Turn

ignition off. With DRB-II in ohmmeter mode, probe

Gray/Light Blue

wire at pedal travel sensor connector. If resistance

is less than

5 ohms, repair Gray/Light Blue wire for a

short to

ground. Perform VERIFICATION

TEST VER-1A. If resistance is more than 5

ohms,

go to next step.

Using

an external ohmmeter, measure resistance between CAB

connector

terminal No. 16 and pedal travel sensor

connector Gray/Light

Blue wire. If

resistance is less than 5 ohms, go to next

step. If

resistance is more than 5 ohms,

repair open Gray/Light Blue wire to

pedal travel sensor. Perform

VERIFICATION TEST VER-1A.

Using

an external ohmmeter, measure resistance between CAB

connector

terminal No. 41 and pedal travel sensor

connector Red/Black

wire. If resistance is less than 5

ohms, go to next step. If

resistance is more

than 5 ohms, repair open Red/Black wire to

pedal

travel sensor. Perform VERIFICATION TEST VER-1A.

Remove

pedal travel sensor from brake booster. Check if

sensor

plunger cap color matches color dot on booster (near sensor).

If

colors match, go to next step. If colors do not match, replace

pedal

travel sensor. Perform VERIFICATION TEST VER-1A.

Using an

external ohmmeter, measure resistance of pedal

travel sensor

while slowly depressing sensor plunger. If sensor

resistance is

as specified, replace CAB. See PEDAL TRAVEL SENSOR

RESISTANCE

table. Perform VERIFICATION TEST VER-1A. If sensor

resistance is

not as specified, replace pedal travel sensor. Perform

VERIFICATION

TEST VER-1A.

PEDAL TRAVEL SENSOR RESISTANCE TABLE

Plunger Position Ohms

Step 1 (Rest) 236-262

Step 2 414-458

Step 3 534-592

Step 4 655-725

Step 5 776-858

Step 6 980-1084

Step 7 Infinity

TEST15A

PUMP MOTOR CIRCUIT NOT WORKING PROPERLY

1) Inspect

ABS pump/motor fuse from Power Distribution Center

(PDC).

If fuse is okay, go to next step. If fuse is not

okay (blown),

perform TEST 15B.

2) Remove ABS pump/motor relay from PDC, and inspect

connector. Repair connector as necessary. With DRB-II in voltmeter mode, probe Red/Dark Green wire (Red/Dark Blue wire on Grand Cherokee and Grand Wagoneer or Red/Brown wire on Wrangler) at ABS pump/motor relay socket terminal "B". If voltage is more than 9 volts, go to next step. If voltage is less than 9 volts, repair open Red/Dark Green wire (Red/Dark Blue wire on Grand Cherokee and Grand Wagoneer or Red/Brown wire on Wrangler) to ABS pump/motor relay.

Connect a

jumper wire between Red/Dark Green wire and

Tan/Black wire

(Brown/White wire and Red/Dark Blue wire on Grand

Cherokee and

Grand Wagoneer or Tan wire and Red/Brown wire on

Wrangler) at ABS

pump/motor relay socket terminals "B" and "D".

Turn

ignition on. Inspect ABS pump/motor fuse. If fuse is okay

(does not

blow), go to next step. If fuse is not okay (blows),

perform TEST 15B.

Listen for

ABS pump/motor operation. If ABS pump/motor is

running, go to

next step. If ABS pump/motor is not running, perform

TEST 15C.

Turn

ignition off. Remove jumper wire. With DRB-II in

ohmmeter mode,

probe Gray/Yellow wire (Gray/Pink wire on Grand

Cherokee and

Grand Wagoneer) at ABS pump/motor relay socket. If

resistance

is less than 5 ohms, go to next step. If

resistance is more

than 5 ohms,

repair open Gray/Yellow wire (Gray/Pink wire on Grand

Cherokee

and Grand Wagoneer) wire between ABS pump/motor relay socket

and

ABS main relay. Perform VERIFICATION TEST VER-1A.

Using

an external ohmmeter, measure resistance of ABS

pump/motor relay

coil terminals No. 85 and 86. See

Fig. 16. If

resistance

is 35-65 ohms, go to next step. If

resistance is not 35-65

ohms, replace

ABS pump/motor relay. Perform VERIFICATION TEST VER-1A.

Disconnect

and inspect CAB 55-pin connector. Repair

connector as necessary.

Turn ignition on. With DRB-II in voltmeter

mode, probe Gray wire

at ABS pump/motor relay socket. If no voltage is

present, go to

next step. If any voltage is present, repair Gray wire

for a

short to battery voltage. Perform VERIFICATION TEST VER-1A.

Turn

ignition off. With DRB-II in ohmmeter mode, probe

Gray

wire at ABS pump/motor relay socket. If resistance is less than

5

ohms, repair Gray wire for a short to

ground. Perform VERIFICATION

TEST

VER-1A. If resistance is more than 5 ohms,

go to next step.

Using

an external ohmmeter, measure resistance between CAB

connector

terminal No. 15 and ABS pump/motor relay

socket Gray wire.

If resistance is less

than 5 ohms, go to next step. If

resistance is

more than 5 ohms, repair

open Gray wire to relay socket. Perform

VERIFICATION

TEST VER-1A.

Turn

ignition off. Reinstall ABS pump/motor relay in PDC.

Apply

battery voltage to CAB connector terminal No. 15, and

go to next

step.

Ensure

ignition is off. With DRB-II in voltmeter mode,

probe

Tan/Black wire (Brown/White wire on Grand Cherokee and

Grand

Wagoneer or Tan wire on Wrangler) at ABS pump/motor 4-pin

harness

connector. If voltage is more than 9 volts,

perform TEST 15D. If

voltage is less

than 9 volts, replace ABS pump/motor

relay. Perform

VERIFICATION TEST

VER-1A.

TEST15B

PUMP MOTOR CIRCUIT NOT WORKING PROPERLY

1) Remove

ABS pump/motor relay (if installed) from Power

Distribution Center

(PDC). Remove jumper wire from ABS

pump/motor

relay socket (if installed).

Turn ignition off, and go to next step.

2) With

DRB-II in ohmmeter mode, probe Tan/Black wire

(Brown/White

wire on Grand Cherokee and Grand Wagoneer or Tan wire on

Wrangler) at ABS pump/motor relay socket. If resistance is less than 5 ohms, repair Tan/Black wire (Brown/White wire on Grand Cherokee and

Grand Wagoneer or Tan wire on Wrangler) for a short to ground. Perform VERIFICATION TEST VER-1A. If resistance is more than 5 ohms, go to next step.

3) Using an external ohmmeter, check ABS pump/motor relay diode. Attach ohmmeter positive and negative leads as shown. See Fig. 17. If continuity exists, replace ABS pump/motor relay. Perform VERIFICATION TEST VER-1A. If no continuity exists, replace ABS pump/motor assembly. Perform VERIFICATION TEST VER-1A.

Fig. 17: Checking ABS Pump/Motor Relay Diode

TEST15C

PUMP MOTOR CIRCUIT NOT WORKING PROPERLY

1) Disconnect

ABS pump/motor 4-pin connector at hydraulic

control unit. Ensure

jumper wire is still connected between Red/Dark

Green

wire and Tan/Black wire (Brown/White wire and Red/Dark Blue wire

on

Grand Cherokee and Grand Wagoneer or Tan wire and Red/Brown wire

on

Wrangler) at ABS pump/motor relay socket.

2) With

DRB-II in voltmeter mode, probe Tan/Black wire

(Brown/White

wire on Grand Cherokee and Grand Wagoneer or Tan wire on

Wrangler) at ABS pump/motor 4-pin harness connector. If voltage is more than 9 volts, go to next step. If voltage is less than 9 volts, repair open Tan/Black wire (Brown/White wire on Grand Cherokee and Grand Wagoneer or Tan wire on Wrangler) to 4-pin harness connector. Perform VERIFICATION TEST VER-1A.

3) Turn ignition off. With DRB-II in ohmmeter mode, probe Black/Tan ground wire (Black ground wire on Grand Cherokee and Grand Wagoneer) at ABS pump/motor 4-pin harness connector. If resistance is less than 5 ohms, replace ABS pump/motor assembly. Perform VERIFICATION TEST VER-1A. If resistance is more than 5 ohms, repair open in Black/Tan ground wire (Black ground wire on Grand Cherokee and Grand Wagoneer). Perform VERIFICATION TEST VER-1A.

TEST15D

PUMP MOTOR CIRCUIT NOT WORKING PROPERLY

Using

an external ohmmeter, measure resistance of ABS

pump/motor

speed sensor. See Fig. 18. If sensor

resistance is 10-35

ohms, go to next

step. If resistance is not 10-35 ohms,

replace ABS

pump/motor assembly.

Perform VERIFICATION TEST VER-1A.

Turn

ignition on. With DRB-II in voltmeter mode, probe Tan

wire (Light

Green/Brown wire on Wrangler) at ABS pump/motor 4-pin

harness

connector. If any voltage is present, repair ABS pump/motor

speed

sensor Tan wire (Light Green wire on Wrangler) for a short

to

battery voltage. Perform VERIFICATION TEST VER-1A. If no

voltage is

present, go to next step.

With

DRB-II in voltmeter mode, probe Dark Blue wire (Brown

wire on

Wrangler) at ABS pump/motor 4-pin harness connector. If any

voltage

is present, repair ABS pump/motor speed sensor Dark Blue wire

(Brown wire on Wrangler) for a short to battery voltage. Perform VERIFICATION TEST VER-1A. If no voltage is present, go to next step.

With

DRB-II in ohmmeter mode, probe Tan wire (Light

Green/Brown wire

on Wrangler) at ABS pump/motor 4-pin harness

connector. If

resistance is less than 5 ohms, repair ABS

pump/motor

speed sensor Tan wire (Light

Green/Brown wire on Wrangler) for a short

to

ground. Perform VERIFICATION TEST VER-1A. If resistance is more

than

5 ohms, go to next step.

With

DRB-II in ohmmeter mode, probe Dark Blue wire (Brown

wire on

Wrangler) at ABS pump/motor 4-pin harness connector. If

resistance

is less than 5 ohms, repair ABS pump/motor

speed sensor

Dark Blue wire (Brown wire

on Wrangler) for a short to ground. Perform

VERIFICATION

TEST VER-1A. If resistance is more than 5 ohms,

go to

next step.

6) Using

an external ohmmeter, measure resistance of Tan wire

(Light

Green/Brown wire on Wrangler) between CAB connector terminal

No. 49 and ABS pump/motor 4-pin harness connector. If resistance is less than 5 ohms, go to next step. If resistance is more than 5 ohms, repair open ABS pump/motor speed sensor Tan wire (Light Green/Brown wire on Wrangler). Perform VERIFICATION TEST VER-1A.

7) Using

an external ohmmeter, measure resistance of Dark

Blue

wire (Brown wire on Wrangler) between CAB connector terminal No.

31

and ABS pump/motor 4-pin harness connector. If

resistance is less

than 5 ohms, replace

CAB. Perform VERIFICATION TEST VER-1A. If

resistance is more than

5 ohms, repair open ABS pump/motor

speed

sensor Dark Blue wire (Brown wire on Wrangler).

Perform VERIFICATION

TEST

VER-1A.

Fig. 18: Checking ABS Pump/Motor Sensor Resistance

TEST16A

RIGHT FRONT INLET VALVE

Disconnect

and inspect Hydraulic Control Unit (HCU) 10-pin

connector. Repair

connector as necessary. Turn ignition on. With DRB-

II in

voltmeter mode, probe White/Tan wire (White/Orange wire on

Grand

Cherokee and Grand Wagoneer or White/Yellow wire on

Wrangler) at HCU

10-pin harness connector. If no voltage is

present, go to next step.

If any voltage is present, repair

White/Tan wire (White/Orange wire on

Grand Cherokee and Grand

Wagoneer or White/Yellow wire on Wrangler)

for a short to battery

power. Perform VERIFICATION TEST VER-1A.

Turn

ignition off. Disconnect and inspect CAB 55-pin

connector. Repair

connector as necessary. With DRB-II in ohmmeter

mode,

probe White/Tan wire (White/Orange wire on Grand Cherokee and

Grand

Wagoneer or White/Yellow wire on Wrangler) at HCU 10-pin

harness

connector. If resistance is

more than 5 ohms, go to next step.

If

resistance is less than 5 ohms,

repair White/Tan wire (White/Orange

wire on Grand Cherokee and

Grand Wagoneer or White/Yellow wire on

Wrangler) for a short to

ground. Perform VERIFICATION TEST VER-1A.

Using an external ohmmeter, measure resistance of

White/Tan wire (White/Orange wire on Grand Cherokee and Grand Wagoneer or White/Yellow wire on Wrangler) between CAB connector terminal No. 38 and HCU 10-pin harness connector. If resistance is less than 5 ohms, go to next step. If resistance is more than 5 ohms, repair open White/Tan wire (White/Orange wire on Grand Cherokee and Grand Wagoneer or White/Yellow wire on Wrangler). Perform VERIFICATION TEST VER-1A.

4) Using an external ohmmeter, measure resistance of right front inlet valve between terminals No. 3 and 5 at HCU pigtail connector. See Fig. 19. If resistance is 5-8 ohms, replace CAB. Perform VERIFICATION TEST VER-1A. If resistance is not 5-8 ohms, replace hydraulic control unit. Perform VERIFICATION TEST VER-1A.

Fig. 19: Checking HCU Right Front Inlet Valve Resistance

TEST17A

RIGHT FRONT OUTLET VALVE

1) Disconnect and inspect Hydraulic Control Unit (HCU) 10-pin

connector. Repair connector as necessary. Turn ignition on. With DRB-II in voltmeter mode, probe Dark Green/White wire at HCU 10-pin harness connector. If no voltage is present, go to next step. If any voltage is present, repair Dark Green/White wire for a short to battery power. Perform VERIFICATION TEST VER-1A.

Turn

ignition off. Disconnect and inspect CAB 55-pin

connector. Repair

connector as necessary. With DRB-II in ohmmeter

mode, probe Dark

Green/White wire at HCU 10-pin harness connector. If

resistance

is more than 5 ohms, go to next step. If

resistance is less

than 5 ohms,

repair Dark Green/White wire for a short to ground.

Perform

VERIFICATION TEST VER-1A.

Using

an external ohmmeter, measure resistance of Dark

Green/White wire

between CAB connector terminal No. 21 and

HCU 10-pin

harness connector. If

resistance is less than 5 ohms, go to next

step.

If resistance is more than 5

ohms, repair open Dark Green/White wire.

Perform

VERIFICATION TEST VER-1A.

Using

an external ohmmeter, measure resistance of right

front outlet

valve between terminals No. 8 and 10

at HCU connector.

See

Fig. 19. If resistance is 3-5 ohms,

replace CAB. Perform

VERIFICATION TEST VER-1A. If resistance is

not 3-5 ohms, replace

hydraulic control

unit. Perform VERIFICATION TEST VER-1A.

TEST18A

RIGHT FRONT SENSOR CIRCUIT FAILURE

1) Using DRB-II, read and record all wheel speed sensor

faults. If RIGHT FRONT SENSOR CIRCUIT FAILURE message is displayed, go to next step. If message is not displayed, perform TEST 19A.

Inspect

right front wheel speed sensor for damage. If

sensor is okay, go

to next step. If sensor is damaged, repair or

replace as

necessary. Perform VERIFICATION TEST VER-1A.

Turn

ignition off. Disconnect and inspect CAB 55-pin

connector.

Repair connector as necessary. Turn ignition on. With DRB-

II

in voltmeter mode, probe White wire at CAB connector terminal

No.

47. If no voltage is present, go to

next step. If any voltage is

present,

repair White wire for a short to battery power. Perform

VERIFICATION

TEST VER-1A.

Turn

ignition off. With DRB-II in ohmmeter mode, probe

White wire at

CAB connector terminal No. 47. If

resistance is more

than 5 ohms,

go to next step. If resistance is less than 5 ohms,

repair

White wire for a short to ground. Perform VERIFICATION TEST

VER-1A.

Using

an external ohmmeter, measure resistance of right

front wheel

speed sensor between White/Dark Blue wire and White wire

at CAB

connector terminals No. 29 and 47.

If resistance is 900-1300

ohms,

replace CAB. Perform VERIFICATION TEST VER-1A. If resistance is

not

900-1300 ohms, go to next step.

Disconnect

right front wheel speed sensor harness

connector. Connector is

located on right rear corner of engine

compartment. Using an

external ohmmeter, measure resistance of right

front

wheel speed sensor at harness connector terminals. If resistance

is

900-1300 ohms, go to next step. If

resistance is not 900-1300 ohms,

replace

sensor. Perform VERIFICATION TEST VER-1A.

Using

an external ohmmeter, measure resistance of White

wire between

CAB connector terminal No. 47 and right

front wheel speed

sensor harness connector. If resistance is less

than 5 ohms, repair

open White/Dark

Blue wire. Perform VERIFICATION TEST VER-1A. If

resistance is

more than 5 ohms, repair open White wire.

Perform

VERIFICATION TEST VER-1A.

TEST19A

RIGHT FRONT SENSOR

Inspect

right front wheel speed sensor for damage. If

sensor is okay, go

to next step. If sensor is damaged, repair or

replace as

necessary. Perform VERIFICATION TEST VER-1A.

Inspect

right front wheel speed sensor tone (pulse) ring

for

damaged teeth or excessive runout. Runout should not exceed

.003"

(.08 mm). Repair

or replace tone ring as necessary. Perform

VERIFICATION TEST VER-1A. If tone ring is okay, go to next step.

Using

a feeler gauge, check right front wheel sensor-to-

tone ring

clearance. If clearance is .036-.050" (.91-1.27 mm),

go to

next step. If clearance is not

.036-.050" (.91-1.27 mm), repair

as

necessary. Perform VERIFICATION TEST

VER-1A.

Inspect

right front wheel speed sensor wiring harness for

damage. If

wiring harness is okay, go to next step. If wiring harness

is

damaged, repair wiring harness as necessary. Perform

VERIFICATION

TEST VER-1A.

Disconnect

right front wheel speed sensor harness

connector. Connector is

located on right rear corner of engine

compartment. Using an

external ohmmeter, measure resistance of right

front

wheel speed sensor at harness connector terminals. If resistance

is

900-1300 ohms, replace CAB. Perform

VERIFICATION TEST VER-1A. If

resistance is not 900-1300

ohms, replace sensor. Perform VERIFICATION

TEST

VER-1A.

NOTE: If excessive axle deflection occurs on extremely bumpy

surfaces or during off road use, it is possible for a wheel speed sensor to set a code.

TEST 20A

RIGHT REAR SENSOR CIRCUIT FAILURE

Using

DRB-II, read and record all wheel speed sensor

faults. If RIGHT

REAR SENSOR CIRCUIT FAILURE message is displayed, go

to next

step. If message is not displayed, perform TEST 21A.

Inspect

right rear wheel speed sensor for damage. If

sensor is okay, go

to next step. If sensor is damaged, repair or

replace as

necessary. Perform VERIFICATION TEST VER-1A.

Turn ignition off. Disconnect and inspect CAB 55-pin

connector. Repair connector as necessary. Turn ignition on. Using DRB-II in voltmeter mode, probe Yellow wire (Yellow/Dark Blue wire on Wrangler) at CAB connector terminal No. 27. If no voltage is present, go to next step. If any voltage is present, perform TEST 20B.

4) Using DRB-II in ohmmeter mode, probe Yellow wire

(Yellow/Dark Blue wire on Wrangler) at CAB connector terminal No. 27. If resistance is more than 5 ohms, go to next step. If resistance is less than 5 ohms, perform TEST 20C.

Using

an external ohmmeter, measure resistance of right

rear

wheel speed sensor between Yellow wire and Yellow/Dark Blue wire

at

CAB connector terminals No. 27 and 45.

If resistance is 900-1300

ohms,

replace CAB. Perform VERIFICATION TEST VER-1A. If resistance is

not

900-1300 ohms, go to next step.

Disconnect

right rear wheel speed sensor. Using an

external ohmmeter,

measure resistance of right rear wheel speed

sensor.

If resistance is 900-1300 ohms, go to next

step. If resistance

is not 900-1300

ohms, replace sensor. Perform VERIFICATION TEST

VER-

1A.

Connect a jumper wire between ground and Yellow/Dark Blue

wire (Yellow wire on Wrangler) at CAB connector terminal No. 45. With DRB-II in ohmmeter mode, measure resistance of Yellow wire (Yellow/Dark Blue wire on Wrangler) at right rear wheel speed sensor harness connector. If resistance is less than 5 ohms, perform TEST 20E. If resistance is more than 5 ohms, perform TEST 20D.

TEST 20B

RIGHT REAR SENSOR CIRCUIT FAILURE

On

Cherokee, repair Yellow wire for a short to battery

power.

Perform VERIFICATION TEST VER-1A. On Wrangler, repair

Yellow/Dark

Blue wire for a short to battery power. Perform

VERIFICATION TEST

VER-1A. On Grand Cherokee and Grand Wagoneer,

disconnect and

inspect Black ABS 8-pin disconnect connector. Connector

is

located behind left kick panel. Repair connector as necessary.

With

DRB-II in voltmeter mode, probe Yellow wire of ABS

disconnect

connector.

If no

voltage is present, repair Yellow wire for a short

to battery

power between right rear wheel speed sensor and ABS

disconnect

connector. Perform VERIFICATION TEST VER-1A. If any voltage

is

present, repair Yellow wire for a short to battery power between

ABS

disconnect connector and CAB 55-pin connector. Perform

VERIFICATION

TEST VER-1A.

TEST 20C

RIGHT REAR SENSOR CIRCUIT FAILURE

On

Cherokee, repair Yellow wire for a short to ground.

Perform

VERIFICATION TEST VER-1A. On Wrangler, repair Yellow/Dark Blue

wire

for a short to ground. Perform VERIFICATION TEST VER-1A. On

Grand

Cherokee and Grand Wagoneer, disconnect and inspect Black

ABS 8-pin

disconnect connector. Connector is located behind left

side kick

panel. Repair connector as necessary. With DRB-II in

ohmmeter mode,

probe Yellow wire of ABS disconnect connector.

If

resistance is less than 5 ohms, repair

Yellow wire for

a short to ground

between right rear wheel speed sensor and ABS

disconnect

connector. Perform VERIFICATION TEST VER-1A. If resistance

is

more than 5 ohms, repair Yellow wire for a

short to ground between

ABS disconnect

connector and CAB 55-pin connector. Perform

VERIFICATION

TEST VER-1A.

TEST 20D

RIGHT REAR SENSOR CIRCUIT FAILURE

On

Cherokee, repair open Yellow/Dark Blue wire to right

rear wheel

speed sensor. Perform VERIFICATION TEST VER-1A. On

Wrangler,

repair open Yellow wire to right rear wheel speed sensor.

Perform

VERIFICATION TEST VER-1A. On Grand Cherokee and Grand

Wagoneer,

disconnect and inspect Black ABS 8-pin disconnect

connector.

Connector is located behind left kick panel. Repair

connector as

necessary. With DRB-II in ohmmeter mode, probe

Yellow/Dark Blue wire

of ABS disconnect connector.

If

resistance is less than 5 ohms, repair

open Yellow/Dark

Blue wire between

right rear wheel speed sensor and ABS disconnect

connector.

Perform VERIFICATION TEST VER-1A. If resistance is more

than 5

ohms, repair open Yellow/Dark Blue wire between

ABS disconnect

connector and CAB 55-pin connector. Perform

VERIFICATION TEST VER-1A.

TEST 20E

RIGHT REAR SENSOR CIRCUIT FAILURE

On

Wrangler, repair open Yellow/Dark Blue wire to right

rear wheel

speed sensor. Perform VERIFICATION TEST VER-1A. On all

others,

disconnect and inspect Black ABS 8-pin disconnect connector.

On

Cherokee, connector is located on transmission hump near

firewall.

On Grand Cherokee and Grand

Wagoneer, connector is located behind left

side

kick panel. Repair connector as necessary. Connect a jumper

wire

between ground and Yellow wire at CAB connector terminal No.

27. With

DRB-II in ohmmeter mode, probe

Yellow wire of ABS disconnect

connector.

If

resistance is less than 5 ohms, repair

open Yellow wire

between right rear

wheel speed sensor and ABS disconnect connector.

Perform

VERIFICATION TEST VER-1A. If resistance is more than 5

ohms,

repair open Yellow wire between ABS

disconnect connector and CAB 55-

pin connector. Perform

VERIFICATION TEST VER-1A.

TEST 21A

RIGHT REAR SENSOR

Inspect

right rear wheel speed sensor for damage. If

sensor is okay, go

to next step. If sensor is damaged, repair or

replace as

necessary. Perform VERIFICATION TEST VER-1A.

Inspect

right rear wheel speed sensor tone (pulse) ring

for

damaged teeth and excessive runout. Runout should not exceed

.003"

(.08 mm). Repair

or replace tone ring as necessary. Perform

VERIFICATION TEST VER-1A. If tone ring is okay, go to next step.

Using

a feeler gauge, check right rear wheel sensor-to-

tone

ring clearance. If clearance is .036-.050" (.91-1.27

mm), go to

next

step. If clearance is not .036-.050" (.91-1.27 mm),

repair as

necessary. Perform

VERIFICATION TEST VER-1A.

Inspect

right rear wheel speed sensor wiring harness for

damage. If

wiring harness is okay, go to next step. If wiring harness

is

damaged, repair wiring harness as necessary. Perform

VERIFICATION

TEST VER-1A.

Disconnect

right rear wheel speed sensor. Using an

external ohmmeter,

measure resistance of right rear wheel speed

sensor. If

resistance is 900-1300 ohms, replace CAB.

Perform

VERIFICATION TEST VER-1A. If

resistance is not 900-1300 ohms,

replace

sensor. Perform VERIFICATION TEST VER-1A.

NOTE: If excessive axle deflection occurs on extremely bumpy

surfaces or during off road use, it is possible for a wheel speed sensor to set a code.

TEST 22A

ABS WARNING LIGHT ILLUMINATION PROBLEM

1) Using DRB-II, read ABS fault codes. If any fault codes are present, perform TEST 1A. Turn ignition off. Remove ABS main relay from PDC, and inspect connector. Repair connector as necessary. Turn ignition on. If ABS warning light comes on, go to next step. If warning light does not come on, perform VERIFICATION TEST VER-1C.

NOTE: A main relay/power circuit failure fault will set with ABS

main relay removed.

Turn

ignition off. With DRB-II in ohmmeter mode, probe

Black/Tan

ground wire (Black ground wire on Grand Cherokee and Grand

Wagoneer)

at ABS main relay socket. If resistance is less than 5

ohms,

go to next

step. If resistance is more than 5 ohms,

repair open

Black/Tan ground wire (Black ground wire on Grand

Cherokee and Grand

Wagoneer). Perform

VERIFICATION TEST VER-1A.

Ensure

ignition off. Disconnect and inspect CAB 55-pin

connector. Repair

connector as necessary. With DRB-II in voltmeter

mode, probe

Gray/Yellow wire (Gray/Pink wire on Grand Cherokee and

Grand

Wagoneer) at ABS main relay socket. If no voltage is present, go

to

next step. If any voltage is present, replace ABS main

relay.

Perform VERIFICATION TEST VER-1A.

Remove

ABS diode. Diode is taped to wiring harness, near

CAB (near ABS

8-pin disconnect connector on Grand Cherokee and Grand

Wagoneer).

Connect a jumper wire between Gray/Yellow wire

(Gray/Pink

wire on Grand Cherokee and Grand Wagoneer) and

Black/Tan wire (Black

wire on Grand

Cherokee and Grand Wagoneer) at ABS main relay socket

terminals

"B" and "E".

Using

DRB-II in ohmmeter mode, probe Gray/Yellow wire at

ABS diode

connector. If resistance is less than 5 ohms,

go to next

step. If resistance is more

than 5 ohms, repair open Gray/Yellow

wire

between relay splice and diode.

Perform VERIFICATION TEST VER-1A.

Remove

jumper wire used in step 4). Turn ignition

on. If

ABS warning light does not come

on, go to next step. If ABS warning

light

comes on, repair Violet wire (Violet/White wire on Grand

Cherokee

and Grand Wagoneer or Light Green/Orange on Wrangler) for a

short

circuit to ground between CAB connector terminal No. 52 and

ABS

diode.

Turn

ignition off. Connect a jumper wire between ground

and

Violet wire (Violet/White wire on Grand Cherokee and Grand

Wagoneer

or Light Green/Orange wire on Wrangler) at CAB connector

terminal

No. 52. Using DRB-II in ohmmeter mode,

probe Violet wire

(Violet/White wire on Grand Cherokee and Grand Wagoneer or Light Green/Orange wire on Wrangler) at ABS diode connector. If resistance is less than 5 ohms, replace ABS diode. Perform VERIFICATION TEST VER-1A. If resistance is more than 5 ohms, repair open Violet wire

(Violet/White wire on Grand Cherokee and Grand Wagoneer or Light Green/Orange wire on Wrangler) between ABS warning light and diode. Perform VERIFICATION TEST VER-1A.

TEST 23A

NO RESPONSE MESSAGE

On

Cherokee, remove and inspect fuse No. 7. If

fuse is

blown, check for possible short to ground in Light

Green/Yellow wire

between ignition switch and terminal No. 53

of CAB connector. If fuse

is

okay, go to next step. On Grand Cherokee and Grand Wagoneer,

remove

and inspect fuse No. 15. If fuse

is blown, check for possible short to

ground in Light

Green/Yellow wire between ignition switch and terminal

No.

53 of CAB connector. If fuse is okay, go

to next step. On

Wrangler, remove and inspect fuse No. 13.

If fuse is blown, check for

possible short to

ground in Yellow/Dark Green wire between ignition

switch and

terminal No. 53 of CAB connector. If fuse

is okay, go to

next step.

On

all models, turn ignition off. Disconnect and inspect

CAB

55-pin connector. Repair connector as necessary. Turn ignition

on.

With DRB-II in voltmeter mode,

probe terminal No. 53 (Light

Green/Yellow

wire on Cherokee and Grand Cherokee and Grand Wagoneer

or

Yellow/Dark Green wire on Wrangler)

of CAB connector.

If

voltage is less than 9 volts, repair open

in Light

Green/Yellow wire (Cherokee and Grand Cherokee and Grand

Wagoneer) or

Yellow/Dark Green wire (Wrangler). Perform

VERIFICATION TEST VER-1A.

If voltage is

more than 9 volts, turn ignition off. With

DRB-II in

ohmmeter mode, probe terminal

No. 1 (Black wire) of CAB connector.

If

resistance is more than 5

ohms, repair open Black wire.

Perform

VERIFICATION TEST VER-1A.

If

resistance is less than 5 ohms, probe

terminal No. 19

(Black wire) of CAB

connector. If resistance is more than 5 ohms,

repair

open Black wire. Perform VERIFICATION TEST VER-1A. If

resistance

is less than 5 ohms, check resistance of

Violet/Brown wire

(White/Violet wire on Wrangler) between

terminals No. 4 of CCD bus

diagnostic connector and No. 23 of CAB connector using an external ohmmeter.

If

resistance is more than 5 ohms, repair

open in

Violet/Brown wire (White/Violet