PVC & CRANKCASE VENTILATION SYSTEM

1988 Jeep Cherokee

1987-89 Crankcase Ventilation PCV AND CCV SYSTEMS

Jeep

DESCRIPTION

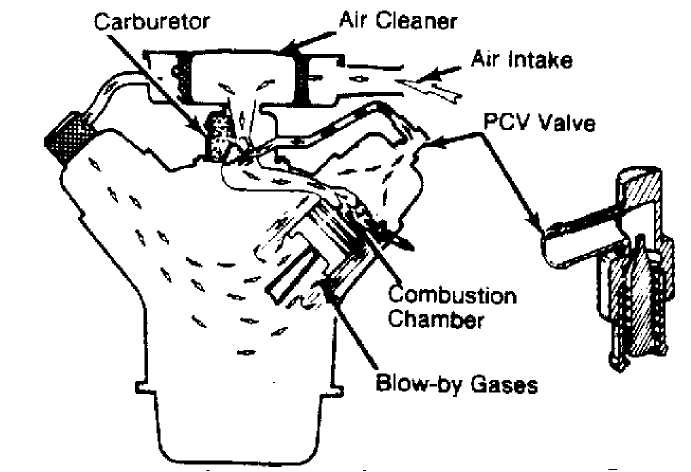

Crankcase ventilation systems are designed to prevent contaminating hydrocarbons from escaping to the atmosphere. This is accomplished by routing vapors from the crankcase through a vacuum-controlled ventilating valve (PCV Valve) into the intake manifold. In the intake manifold, the crankcase vapors mix with the air/fuel mixture and are burned in the combustion process. PCV systems are used on all 4.2L and 5.9L engines. 2.5L and 4.0L engines do not employ PCV systems, instead they are equipped with a Crankcase Ventilation System (CCV). The CCV system performs the same function as a conventional PCV system, but does not use a vacuum controlled valve.

OPERATION

PCV SYSTEM

Air is supplied to the crankcase ventilation system through a crankcase ventilating filter assembly, located in air cleaner housing or on rocker arm cover.

When engine is operating, fresh air enters crankcase ventilation system through the air cleaner and filter.

Air then flows into the rocker arm cover and valve compartment. It combines with blow-by gas and unburned air/fuel mixture and burns in combustion chamber. See Fig. 1.

Fig. 1: Typical Crankcase Ventilation System

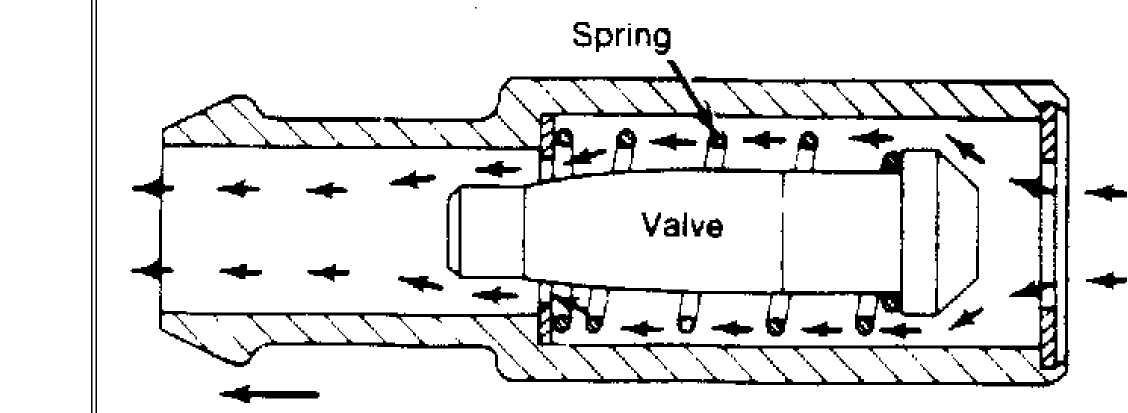

Ventilator valve is held closed by spring pressure when engine is not running. See Fig. 2. This prevents accumulation of hydrocarbon fumes from collecting in intake manifold, which could

result in hard starting.

Fig.

2:

Fig.

2:

Òî Carburetor

Typical PCV Valve & Airflow

When engine is started, manifold vacuum pulls valve open against spring pressure. As long as there is engine vacuum, the valve floats, permitting crankcase fumes to enter intake manifold.

A baffle in rocker arm cover prevents oil from being drawn into intake manifold through ventilator valve.

If the engine backfires, the ventilator valve will close. This will prevent ignition of fumes in crankcase.

During certain engine operations, more blow-by is created than ventilator valve can handle. Excess blow-by is returned to air cleaner and carburetor through rocker arm cover and breather assembly. It is then burned in the combustion chamber.

A breather assembly acts as separator to keep oil from being drawn into air cleaner during this operation.

CCV SYSTEM

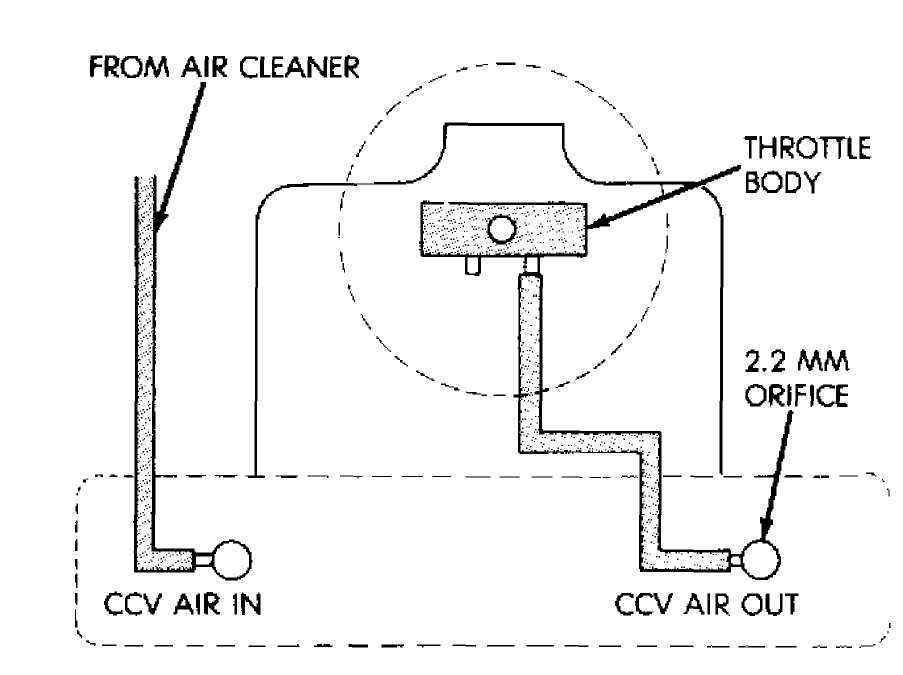

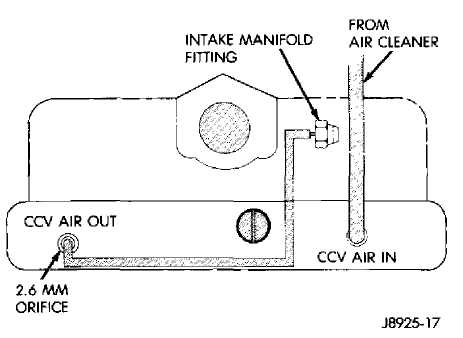

As stated above, the CCV system performs the same function as a conventional PCV system, but does not use a vacuum controlled valve.

A molded vacuum tube connects manifold vacuum to a grommet on top of the cylinder head cover at the dash panel end. The grommet contains a metered orifice of a calibrated size that meters the amount of crankcase vapors drawn out of the engine. A fresh air supply hose from the air cleaner is also connected to the front of the cylinder head cover on 4.0L engines and to the rear of the cover on 2.5L engines.

When the engine is operating, fresh air enters the engine and mixes with crankcase vapors. Manifold vacuum draws the vapor/air mixture through the metered orifice and into the intake manifold. The vapors are consumed during combustion.

Fig. 3: CCV System 2.5L Engine

MW 29 159ã

_ I

i ß ^Ì× ...„

. , 1992

MW 29 159ã

_ I

i ß ^Ì× ...„

. , 1992

Fig. 4: CCV System 4.0L Engine

TESTING

To test crankcase ventilation system, start engine and allow it to reach normal operating temperature. Make sure engine is idling at normal curb idle, and perform following checks:

Remove

PCV valve from its mounting. If valve is

functioning properly,

hissing noise will be heard as air passes

through

it. Strong vacuum should be felt when your finger is placed

over

valve inlet.

While

finger is over inlet, check for presence of vacuum

leaks in hose

line and at all connections. Reinstall PCV valve,

remove

crankcase air inlet hose at air cleaner.

Loosely

hold piece of stiff paper over opening at end of

inlet hose.

Paper should be sucked against hose opening with

noticeable force

after sufficient time has elapsed for crankcase

pressure to lower

(usually about a minute). For final check,

stop

engine, remove PCV valve and shake

it. Metallic clicking noise should

be heard, indicating valve is

free.

If system

passes both engine running and stopped tests,

it is functioning

properly. No further tests are required. If it has

failed either

test, replace appropriate components and retest. If it

does not

pass on second try, clean system.

MAINTENANCE

Engine may idle slow or rough due to clogged ventilator valve or system. Therefore, never adjust carburetor idle without first checking valve and system.

If ventilator valve or system becomes clogged, all crankcase ventilation will stop, and serious engine damage could result.

Although following manufacturers’ service procedures give specific intervals, it is recommended the crankcase ventilation system be checked more frequently if vehicle is operated under severe conditions (extreme dust, prolonged idling, trailer hauling or short trips in cold weather).

PCV VALVE

Replace PCV valve every 30,000 miles. Valve is located on rocker arm cover of 4-cylinder, 6-cylinder and V6 models and on intake manifold of V8 models.

FILTER ELEMENT

Clean filter element every 30,000 miles. Filter is located inside air cleaner of 4-cylinder, 6-cylinder and V6 models and in oil filler cap of V8 models.