TRANSFER CASE - NP/NV 242

1988 Jeep Cherokee

1987-96 TRANSFER CASES Jeep - New Venture 2 42

Cherokee, Comanche, Wagoneer, Grand Wagoneer

IDENTIFICATION

Transfer case can be identified by an I.D. tag, located on rear case. I.D. tag provides model number, serial number and low range ratio. Date of manufacture is the serial number (I.D. number). This information is necessary when ordering parts.

DESCRIPTION

Model 242 transfer case is a chain-driven, 2-piece aluminum case, with full time operation. Torque input in 4WD high and low range is undifferentiated.

ADJUSTMENTS

GEARSHIFT LINKAGE

Remove shift boot and shift to 4L position. Loosen trunnion nut. Adjust trunnion and shift rod until rod fits freely. Tighten trunnion nut and remove shim.

TROUBLE SHOOTING

SYMPTOM DIAGNOSIS

Will Not Shift Or Difficult To Shift Into Gear

Check fluid level. Check linkage adjustment. Ensure transfer

case external linkage is not binding. Internal parts may be worn or

damaged.

Noisy In All Gears

Check fluid level. Ensure correct fluid is used. If fluid is okay, locate noise and check for possible internal mechanical problem.

Jumps Out Of Gear Or Noisy In 4WD

Transfer case not completely in gear; check shift linkage. Range fork damaged. Inserts are worn. Shift fork binding on shift rail. Low range gear worn or damaged.

Fluid Leaking From Vent Or Seals

Transfer case overfilled. Vent plugged. Output shaft seals are damaged or not installed properly.

Transfer Case Will Not Shift Through High Lock Range Incomplete shift due to driveline torque load; momentarily release accelerator pedal to complete shift. Check tire pressure and tire wear. Vehicle overloaded; remove load and check shifting.

ON-VEHICLE SERVICE

FRONT OIL SEAL

Removal & Installation

Mark front

propeller shaft and flange for alignment

purposes. Remove front

propeller shaft. Remove flange. Discard washer

and nut. Using a

screwdriver, carefully remove oil seal. Ensure seal

contact

surface is clean.

Apply ATF

to seal lip and yoke seal surface. Install oil

seal and flange

with new washer and nut. Install front propeller shaft

using

alignment marks. Check transfer case fluid.

EXTENSION HOUSING OIL SEAL & BUSHING

NOTE: When replacing oil seal, DO NOT remove extension housing.

Removal & Installation

Mark rear

propeller shaft and flange for installation

purposes. Remove rear

propeller shaft. Remove bolts and tap extension

housing in a

clockwise direction and remove extension housing. DO NOT

pry on

extension housing. Using a screwdriver, remove oil seal

from

extension housing.

Using

bushing driver, replace bushing in extension

housing. Install new

extension housing oil seal. Apply silicone

sealant to extension

housing mating surface. Install extension

housing. Reverse

removal procedure to complete installation.

REMOVAL & INSTALLATION

TRANSFER CASE

Removal & Installation

Shift

transfer case into Neutral position and drain fluid.

Mark front

and rear drive shaft for installation purposes. Remove

front and

rear drive shafts. Disconnect vacuum lines and speedometer

cable.

Remove rear crossmember.

Disconnect

shift linkage. Support transfer case with a

jack. Separate

transfer case from transmission. Remove transfer case.

To

install, reverse removal procedure. Tighten bolts to

specification.

See TORQUE SPECIFICATIONS. Adjust shift linkage,

if necessary.

TRANSFER CASE DISASSEMBLY

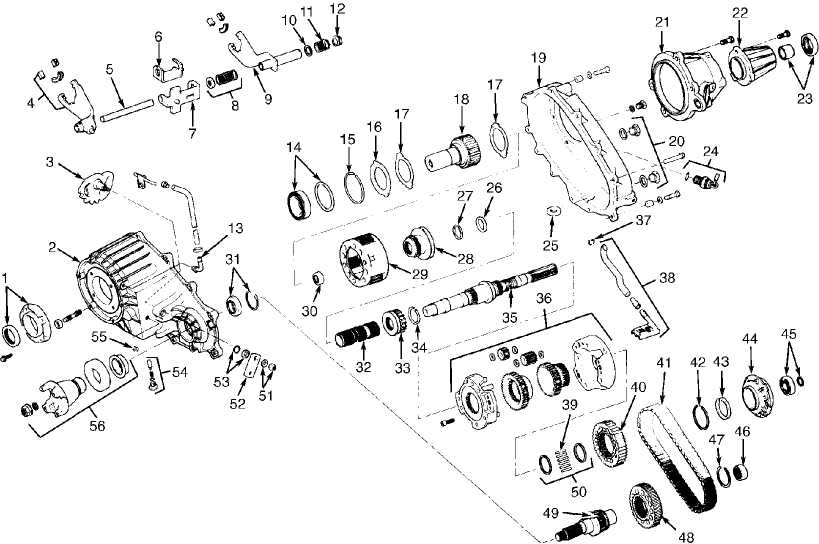

1) Remove

drain and fill plugs. See Fig. 1. Remove

front

companion flange, washer and seal.

Place transfer case in 4L position.

Remove

extension housing. See EXTENSION HOUSING OIL SEAL &

BUSHING

under

ON-VEHICLE SERVICE. Remove rear bearing snap ring. Remove

rear

bearing retainer. Separate rear case from front case using

prybars or

screwdriver. DO NOT damage

mating surfaces.

NOTE: DO NOT disassemble oil pump, replace as unit only.

Remove

oil pump, pick-up tube and screen from rear case.

Remove pick-up

tube "O" ring from oil pump.

Remove magnet from front

case. Remove

drive sprocket snap ring. Remove drive sprocket and drive

chain.

Remove

front output shaft. Remove shift lever from sector

shaft. Remove

shift detent plug, spring and plunger. Remove plug from

low range

fork lock pin access hole. Move shift sector until lock pin

is

aligned with hole. Remove lock pin with No. 1 screw

extractor.

Remove

shift rail from fork assembly. Remove mode fork and

mainshaft as

an assembly. Record mode sleeve position. Remove mode

shift

sleeve and mode fork assembly. Remove sleeve from fork. Remove

intermediate clutch shaft snap ring from mainshaft.

Remove

clutch shaft thrust ring. Remove intermediate

clutch shaft.

Remove differential retaining snap ring. Remove

differential

assembly. Remove differential needle bearings and thrust

washers

from mainshaft. Remove low range fork and

hub.

Remove

shift sector. Remove shift sector bushing and "O"

ring.

Remove front bearing retainer. Remove input gear snap ring.

Using

a press, remove input and low range gear assembly from input

gear

bearing. Remove low range gear snap ring.

Remove

input gear retainer, thrust washers and input gear.

Mark

differential halves for reassembly purposes. Separate

differential

halves. Remove planetary gear and thrust washers.

Record

mainshaft gear and sprocket gear position. Remove

gears. Remove

front output shaft front bearing oil seal, snap ring and

front

bearing. Using a press, remove input gear bearing.

Using

slide hammer and internal puller, remove input gear

pilot

bearing. Using slide hammer and internal puller, remove front

output

shaft rear bearing.

Front Bearing Retainer & Seal

Front Case

Shift Sector

Low Range Fork & Inserts

Shift Rail

Shift Bracket

Slider Bracket

Bushing & Spring

Mode Fork & Inserts

Bushing

Fork Spring

Bushing

Vent Tube

Input Gear Bearing & Snap Ring

Low Range Gear Snap Ring

16 Low Range Gear Retainer

Low Range Gear Thrust Washer

Input Gear

Rear Case

Drain & Fill Plugs

Rear Bearing Retainer

Extension Housing

Bushing & Oil Seal

Vacuum Switch(lf Equipped)

Magnet

Thrust Ring

Snap

Ring

28 Shift Sleeve

Low Range Gear

Pilot Bushing

Front

Output Shaft Front

Bearing & Snap

Ring

Intermediate Clutch Shaft

Shift Sleeve

Snap Ring

Mainshaft

Differential Assembly

Oil Pick-Up Tube "O" Ring

Oil Pick-Up Tube & Screen

Mainshaft Bearing Rollers

Drive Sprocket

Drive Chain

Snap Ring

Oil Pump Seal

Oil Pump

Rear Bearing & Snap Ring

Front

Output Shaft

Rear Bearing

Snap Ring

Driven Sprocket

Front Output Shaft

Mainshaft Bearing Spacers

Shift Lever Washer & Nut

Shift Lever

Sector "O" Ring & Seal

Detent Pin, Spring & Plug

Seal Plug

Companion

Flange, Nut, Seal,

Washer &

Oil Slmger

Fig. 1: Exploded View Of Model 242 Transfer Case Courtesy of Chrysler Motors.

CLEANING & INSPECTION

Clean

all parts with solvent. Dry with compressed air.

Replace all oil

seals, "O" rings and snap rings.

Check all parts for

wear or damage.

Replace all worn or damaged parts. Apply Dexron II to

all parts

before installing.

Inspect

low range annulus gear inside front case. If gear

is worn or

damaged, replace case and gear as an assembly. Replace oil

pump

as an assembly if any part is damaged or worn.

NOTE: When installing bearings, ensure bearing bores are aligned with oil feed holes.

TRANSFER CASE REASSEMBLY

Install

front output shaft front bearing, snap ring and

oil seal. Install

snap ring on input gear bearing. Using a wooden

block and press,

install input gear until snap ring is against case.

Install

input gear pilot bearing. Assemble low range gear,

thrust

washers, input gear and retainer. Install low range gear snap

ring.

Ensure snap ring is seated properly in groove.

Start

input gear shaft through the bearing in front case.

Using a

press, install input gear shaft through bearing. Ensure

adapter

is positioned properly before pressing shaft.

NOTE: Ensure proper size tool is used to press input gear shaft; wrong size tool can damage case and thrust washers and will move pilot bearing too far into gear bore.

Install

input gear snap ring. Install front bearing

retainer oil seal.

Apply 1/8" bead of silicone sealant

to front

bearing retainer mating surface. Install front bearing

retainer on

front case. Install sector

shaft "O" ring and bushing.

Install shift

sector.

Install

detent pin, spring and plug. Install low range

fork pads.

Assemble low range fork and hub. Ensure low range fork pin

is

engaged in shift sector slot. Install differential sprocket gear

in

lower differential case. Install planet gears and new thrust

washers

on lower case pins.

Ensure

thrust washers are positioned on top and bottom of

each planet

gear. Install mainshaft gear. Align marks on upper and

lower

differential case. Install bolts and tighten to specifications.

See

TORQUE SPECIFICATIONS. Install needle bearing spacer on mainshaft.

Using

petroleum jelly to hold needles, install bearings on

mainshaft.

Install other spacer. Install differential assembly. Ensure

all

needle bearings are in place. Install differential snap

ring.

Install intermediate clutch shaft. Install thrust washer

and snap

ring. Install mode shift sleeve in mode fork.

Install

mode fork assembly on mainshaft. Ensure mode shift

sleeve splines

engage with differential splines. Install mode fork and

mainshaft

assembly in case. If necessary, rotate mainshaft slightly to

engage

mainshaft with low range components.

Install

mode fork pin into shift sector slot. Install

shift rail. Ensure

shift rail is seated in shift forks. Rotate shift

sector so lock

pin can be installed. Install lock pin so tapered end

is in fork

and rail. Install plug. Install shift lever and nut on

shift

sector shaft.

Install

detent plunger, spring and plug. Install front

output shaft.

Install drive chain and sprocket. Install drive sprocket

snap

ring. Install front output shaft rear bearing.

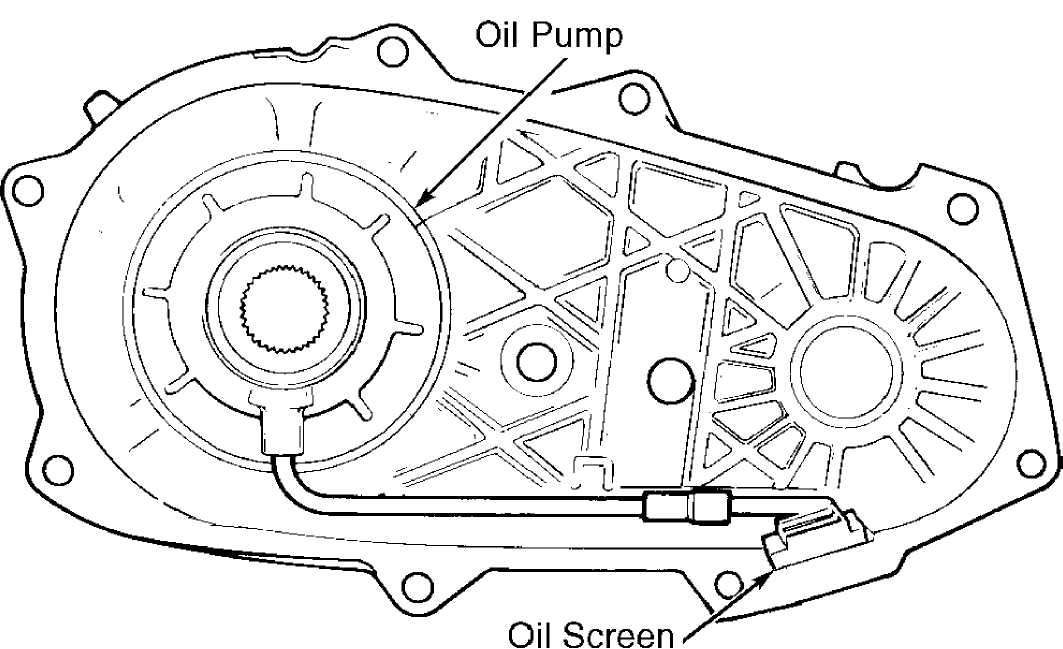

Install

oil seal in oil pump housing. Assemble oil pump

gears in housing.

Ensure oil feed hole is aligned with hole in

housing. Install oil

pump screws. Tighten to specification. Install

"O" ring in oil pump. Install oil pick-up tube and screen. Ensure screen is properly positioned. See Fig. 2.

Install

magnet in front case. Apply 1/8" bead

of silicone

sealant to front case

mating surface. Assemble case halves together.

Tighten

to specification. Ensure mainshaft splines are engaged with

oil

pump inner gear and a washer is used on bolts at dowel locations.

Install

rear retainer bearing in retainer. Apply 1/8"

bead

of silicone sealer and install retainer to case. Install

rear

bearing snap ring. Install

extension housing. Install front companion

flange.

Install vacuum switch and drain plug. Fill transfer case with

Dexron

II.

92113084

Fig. 2: Identifying Oil Pump Screen Position Courtesy of Chrysler Motors.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application

Ft. Lbs. (N.m)

Companion Flange Nut 90-130 (122-176)

Detent Plug 14 (19)

Drain & Fill Plug 27 (37)

Extension Housing Bolt 26 (35)

Front Bearing Retainer Bolt 12 (16)

Front Case-to-Rear Case Bolt 26-34 (35-46)

Shift Fork Set Screw 15 (20)

Transfer Case-to-Transmission 26 (35)