DRIVE SHAFT ALIGNMENT

1988 Jeep Cherokee

1988 Drive Shafts Alignment

DESCRIPTION

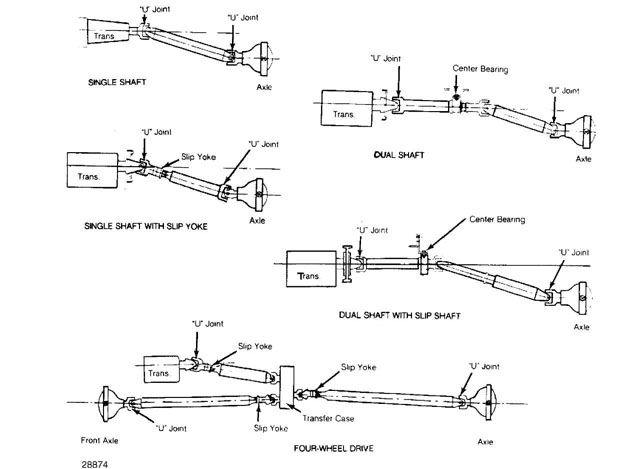

Drive shafts are balanced, one-piece, tubular shafts with universal joints at each end. Number used in vehicle varies: one shaft, 2 shafts with a center bearing, or 3 shafts. Three shafts are used in many 4WD applications. Location of slip joints varies with model and manufacturer. See Fig. 1.

Fig. 1: View of 5 Commonly Used Drive Shaft Combinations Many 4WD models use 3 drive shafts.

INSPECTION

Vibration can come from many sources. Before overhauling driveline, check other sources of possible vibration as follows:

Tires and wheels - Check tire inflation and wheel balance.

Check for foreign objects in tread, damaged tread, mismatched

tread patterns or incorrect tire size.

Center Bearing - Tighten drive shaft center bearing

mounting bolts. If bearing insulator is deteriorated or

oil-soaked, replace it.

Engine & Transmission Mountings - Tighten mounting bolts.

If mountings are deteriorated, replace them.

Drive Shaft - Check drive shaft for damage or dents that

could affect balance. Check for undercoating adhering to

shafts. If present, clean shafts thoroughly.

Universal Joints - Check for foreign material stuck in

joints. Check for loose bolts and worn bearings.

ADJUSTMENTS

DRIVE SHAFT PHASING

One-Piece Shafts

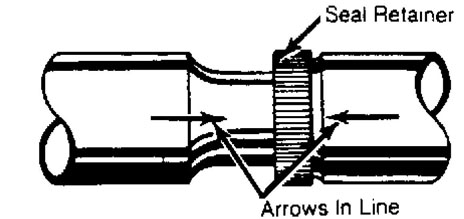

Check that flanges on either end of drive shaft are in same plane. Often there are arrows on slip joint and drive shaft to aid in alignment. See Fig. 2. If flanges are not in same plane, disassemble universal joint and align.

Fig. 2: Slip Joint Alignment Arrows Align arrows for proper shaft phasing.

2-Piece Shafts

1) All General Motors models with 32 splines use keys on spline and slip joint, which can only mate in correct position. On most models with 2-piece shafts, proper phasing is accomplished by keys on spline and slip joint.

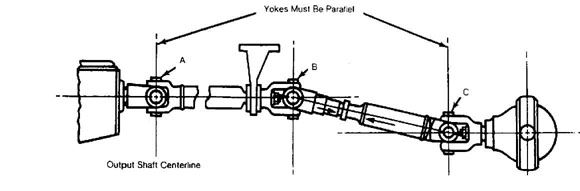

2) On models with 2-piece shafts, rotate transmission yoke

until trunnion is in horizontal plane. Install front drive shaft with

"U" joint trunnion in vertical plane. Connect bearing support to

crossmember.

3) Ensure that front face of bearing support is perpendicular

(90 degrees) to centerline of drive shaft. Install rear drive shaft

with "U" joint trunnion of slip joint in vertical plane.

4) Set differential pinion yoke trunnion in vertical plane.

Connect rear drive shaft to pinion yoke. If 2-piece shaft is correctly

installed, centerline of trunnions at each end of individual shafts

will be parallel. See Fig. 3.

28880

Fig. 3: Phase Alignment Of 2-Piece Drive Shafts Trunnion yoke ears on each shaft must be parallel.

DRIVE SHAFT BALANCE TEST

1) Drive shaft imbalance may often be cured by disconnecting

shaft and rotating it 180 degrees in relation to other components.

Test by raising rear wheels off ground, and turning shaft with engine.

NOTE: DO NOT run engine without ram airflow across radiator for

prolonged periods, as overheating of engine or transmission may occur.

On most models, balance testing may be done by marking

shaft in 4 positions, 90 degrees apart. Place marks approximately 6"

forward of weld, at rear end of shaft. Number marks one through 4.

Place screw-type hose clamp so clamp head is in number one

position, and rotate shaft with engine. If there is little or no

change, move clamp head to No. 2 position, and repeat test.

Continue procedure until vibration is at lowest level. If

no difference is noted with clamp head moved to all 4 positions,

vibrations may not be drive shaft imbalance.

If vibration is lessened but not completely gone, place 2

clamps at that point, and run test again. Combined weight of clamps in

one position may increase vibration. If so, rotate clamps 1/2" apart,

above and below best position, and repeat test.

Continue to rotate clamps as necessary, until vibration is

at lowest point. If vibration level is still unacceptable, leave rear

clamp(s) in position and repeat procedure at front end of drive shaft.

If vibration can be eliminated or reduced to acceptable levels using

this test procedure, send drive shaft out to be balanced.

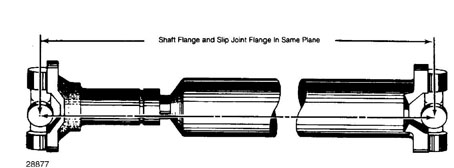

Fig. 4: Drive Shaft Phase Alignment

Align drive shaft and slip joint trunnions in same plane.

FLANGE ALIGNMENT & RUNOUT

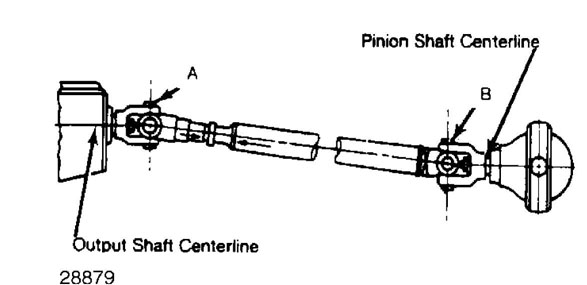

1) All flanges must be perpendicular in both vertical and horizontal planes to engine crankshaft. Only exception is "broken back" type driveline, which has flanges that are not perpendicular in vertical plane. See Fig. 5.

Fig. 5: Typical "Broken Back" Type Drive Shaft Alignment Angle "A" equals angle "B".

With nonparallel or "broken back" type installation,

working angles of universal joints of given drive shaft are equal.

Angle "A" = angle "B" .

This is calculated as follows: angle of output shaft

centerline is subtracted from angle of drive shaft. Difference should

equal angle of drive shaft subtracted from pinion shaft angle.

Parallel type joints maintain constant velocity between

output shaft and pinion shaft. Vibration is minimized and component

life maximized when universal joints are parallel.

Fig. 6: Aligning One-Piece Drive Shaft Yokes must be parallel.

Using dial indicator, measure runout of transmission

flange, center bearing flange and pinion flange. If runout exceeds .

003-.005" (.08-.13 mm), replace flange.

If dial indicator cannot be used, push rod with snug fit

through flange bearing bore. See if it aligns with opposite flange

bore. If not, replace flange.

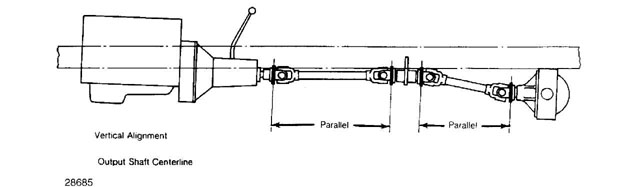

Rotate transmission flange until it is vertical, measuring

from side. Check center bearing and pinion flanges. They cannot be

more than one degree off vertical. See DRIVE SHAFT PHASING in this

article.

Fig. 7: Vertical Alignment of Drive Shaft Flanges in pairs should be parallel.

8) Rotate transmission flange until it is vertical, measured from side. Measure angle from end and record it. Check all other flanges for same angle. They must be within 1/2 degree of each other. Adjust as required.

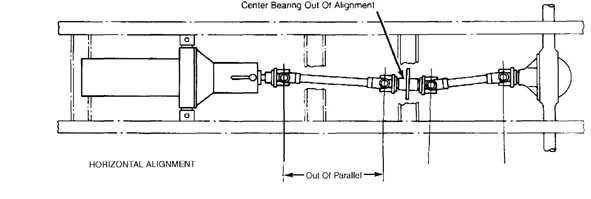

9) If difficulty is encountered when making these adjustments, horizontal alignment should be checked. Even though vertical alignment is correct, horizontal alignment can be badly out of adjustment. This is often found after major component replacement or repair of serious accident damage. See Fig. 8.

28881

Fig. 8: Horizontal Alignment of Drive Shaft Plane of trunnions should be parallel.

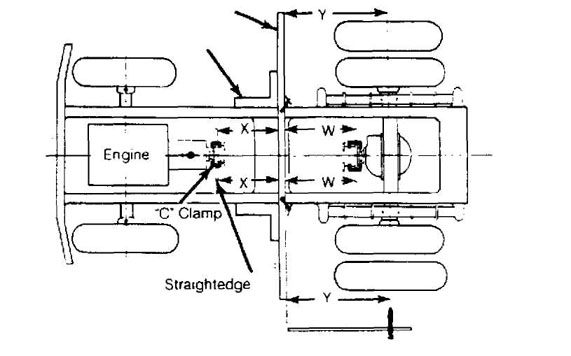

10) To make horizontal alignment checks, set straightedges up. See Fig. 9. Set transmission output flange horizontal and clamp straightedge to flange in a horizontal plane. Repeat procedure with drive pinion flange. Ensure that flanges are horizontal by checking angle of straightedge with spirit level.

Straightedge Framing Square

28882

Fig. 9: Checking Horizontal Alignment

Measure at 6 points shown using straightedges and framing squares.

11) Using straightedge that is 12" longer than width of rear wheel track at 90 degrees, clamp to frame side rails. Use large

framing squares to align straightedge with side rails.

Measure distance "X" at each side. If both measurements

are not within 1/16" (1.6 mm) of each other, transmission flange is

horizontally misaligned.

Measure distance "Y" (edge of straightedge to axle shaft

centerline) at each side. If 2 dimensions are not within 1/8" (3.2 mm)

of each other, axle housing is misaligned.

Measure distance "W" at each side. If both measurements

are not within 1/16" (1.6 mm) of each other, pinion flange is

horizontally misaligned.