TRANSFER CASE - COMMAND TRAC DIAGNOSIS

1988 Jeep Cherokee

1984-90 Drive Axles - Transfer Case - Electronic Diagnosis Cherokee, Wagoneer, Wrangler (1987-90)

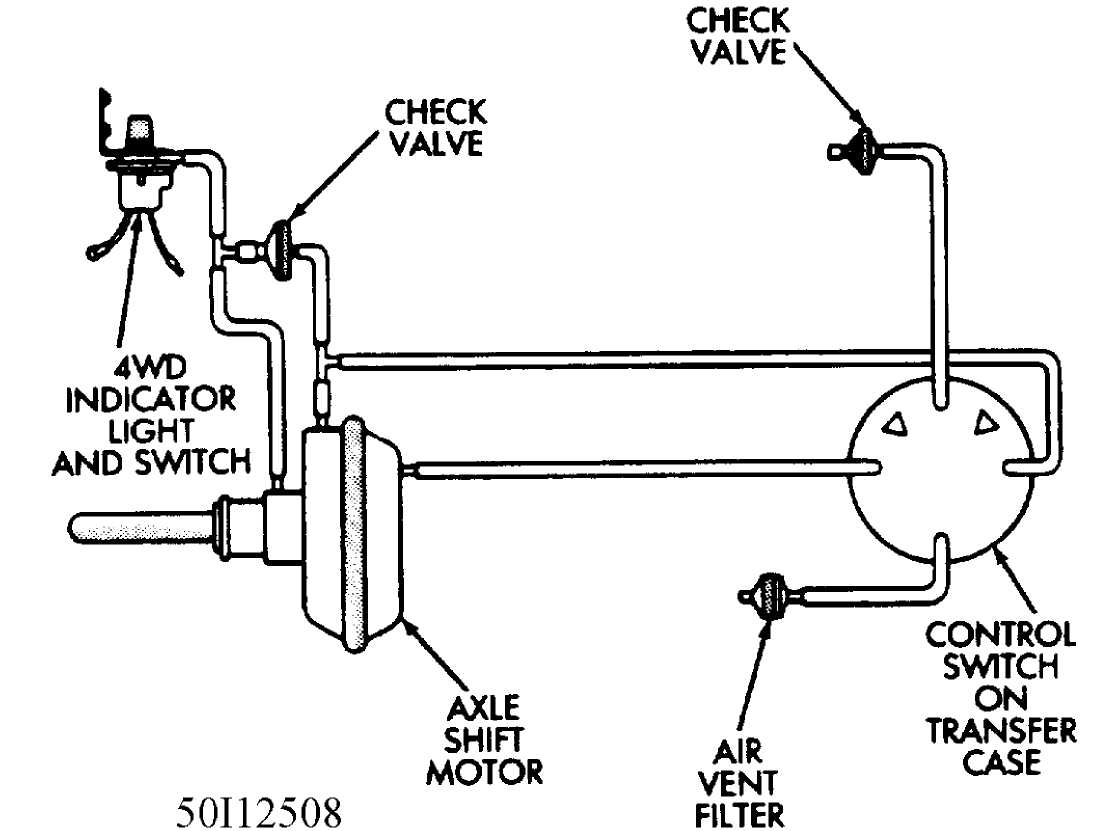

VACUUM CONTROL SYSTEM

The Command-Trac vacuum switch consists of a vacuum control switch on the transfer case, an air vent filter, a vacuum shift motor (located on front axle), a four-wheel drive indicator light and vacuum switch, two vacuum check valves and an interconnecting vacuum harness. See Fig. 1.

Fig. 1: Command-Trac Vacuum Control System

AXLE SHIFT MOTOR FUNCTIONAL TEST

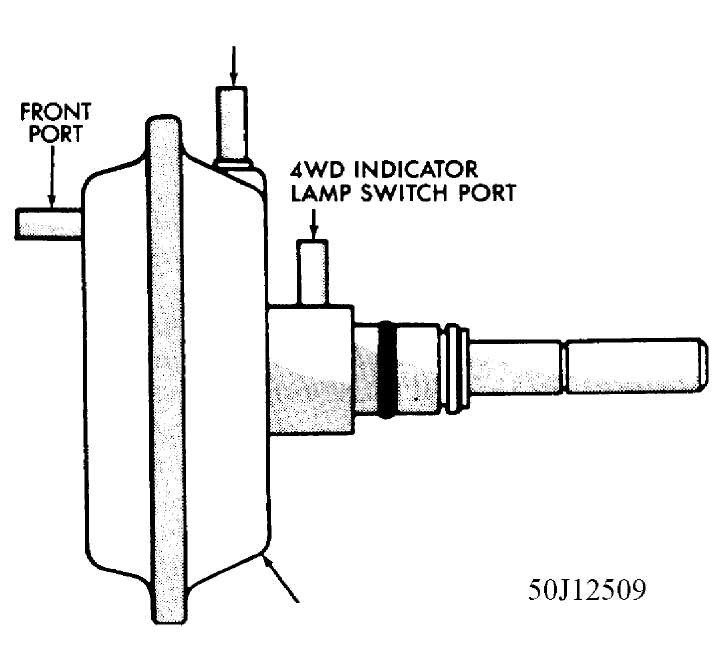

1) Raise vehicle. Disconnect vacuum harness from axle shift motor and connect a vacuum pump to vacuum shift motor port. See Fig. 2.

Apply

15 in. Hg. (51 kPa)

of vacuum to front port and

rotate

right front wheel to fully disengage outer and intermediate

axle

shafts (i.g., into two wheel drive operation).

The

shift motor should maintain vacuum applied to front

port

for a minimum of 30 seconds. If motor does

not maintain vacuum,

replace it. If

motor does maintain vacuum, proceed to next step.

Disconnect

vacuum pump from vacuum shift motor front port.

See

Fig. 2. Connect vacuum pump to vacuum

shift motor rear port, cap

port for

indicator lamp sw., and apply 15 in. Hg

(51 kPa) of vacuum to

rear

port.

The

shift motor should maintain the vacuum applied to rear

port

for a minimum of 30 seconds. If shift

motor does not maintain

vacuum, replace it. If motor does

maintain vacuum, proceed to next

step.

Remove cap

from port for indicator lamp sw. and determine

if vacuum was

present at this port. If vacuum was present, the shift

motor

functions normally. If vacuum was not present, proceed to next

step.

Apply

15 in. Hg. (51 kPa)

of vacuum to shift motor rear

port.

Rotate right front wheel as necessary and ensure that outer

and

intermediate axle shafts are completely engaged. The axles

must be

completely engaged (i.e. into

four-wheel drive operation) to open port

for

indicator lamp switch.

Determine

if vacuum is present at port for indicator lamp

switch again. If

vacuum was present at por, shift motor functions

normally. If

vacuum was not present at port, replace shift motor.

SHIFT MOTOR

Fig. 2: Axle Vacuum Shift Motor

REAR PORT

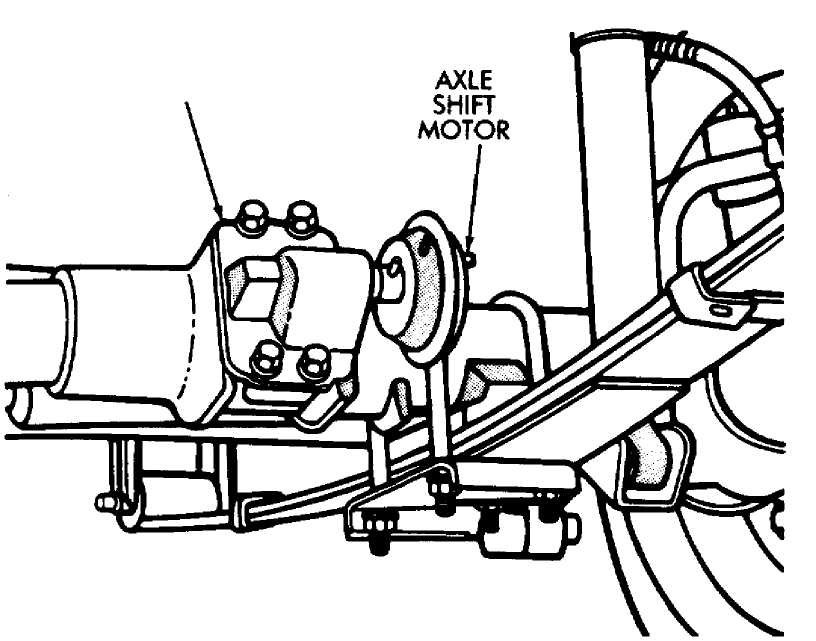

AXLE SHIFT MOTOR AND HOUSING REMOVAL & INSTALLATION

REMOVAL (60/70 SERIES AND MODEL 81 VEHICLES)

Raise and

support vehicle. Position a drain pan under

shift motor housing.

Disconnect vacuum harness.

Remove

housing attaching bolts. Remove housing, motor and

shift fork as

a unit. See Fig. 3.

Mark shift fork and housing for installation reference.

Rotate

shift motor and remove shift fork and motor

retaining

snap rings.

Remove shift motor from housing.

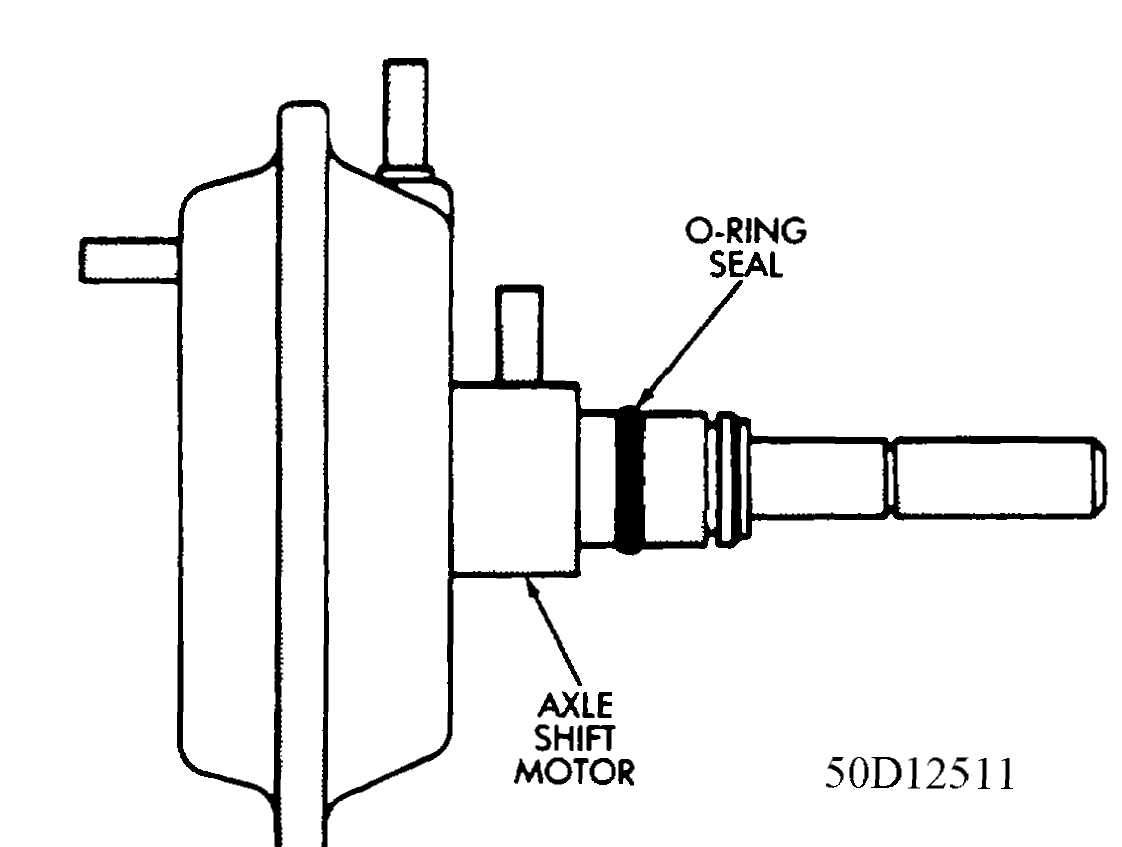

Remove

O-ring seal from shift motor shaft. See Fig. 4.

Discard

O-ring seal.

INSTALLATION (60/70 SERIES AND MODEL 81 VEHICLES)

Add

5 ounces (148 ml)

of SAE 75W-90 grade GL 5 gear

lubricant

to axle through shift motor housing opening.

Insatll

a replacement O-ring seal on shift motor shaft.

See

Fig. 4.

Insatll

shift motor in housing with retaining snap rings

and slide shift

fork onto shaft with reference mark aligned.

Engage

shift fork with shift collar and install housing

attaching

bolts. See Fig. 3. Tighten bolts with 101

inch-lbs. (11 N.m)

torque.

Connect vacuum harness to shift motor and lower vehicle.

AXLE

SHIFT

MOTOR

50C12510

Fig. 3: Axle Vacuum Shift Motor and Housing

HOUSING

Fig. 4: Axle Vacuum Shift Motor Shaft O-Ring Seal