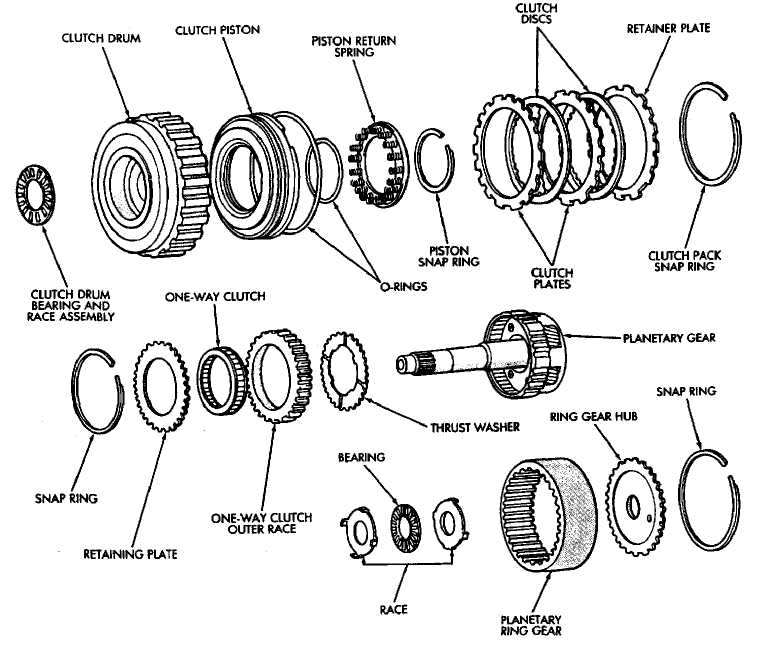

OVERDRIVE PLANETARY GEAR AND CLUTCH OVERHAUL

Gear And Clutch Disassembly

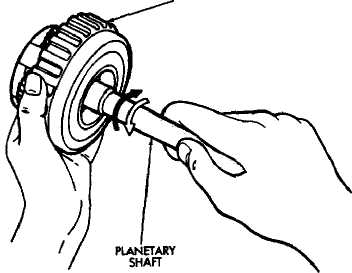

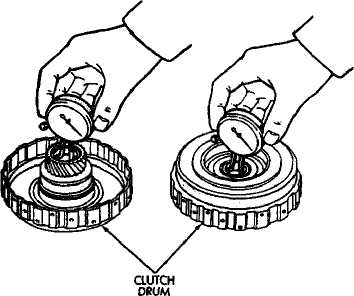

Check operation of one-way clutch in clutch drum.

Hold drum and turn planetary shaft clockwise and

counterclockwise. Shaft should turn clockwise freely

but lock when turned counterclockwise. Replace one

way clutch if necessary.

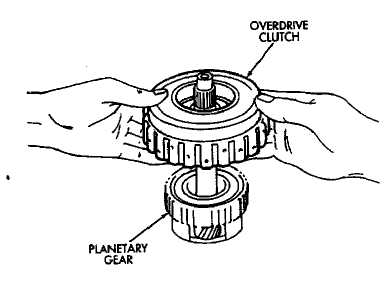

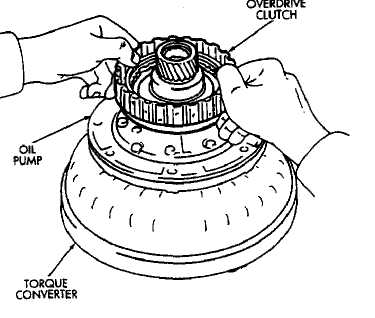

Remove overdrive clutch from planetary gear (Pig.

3).

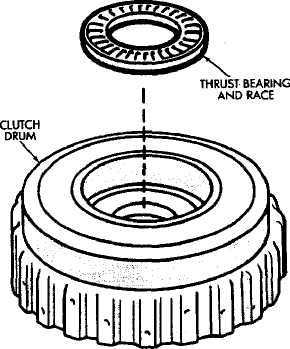

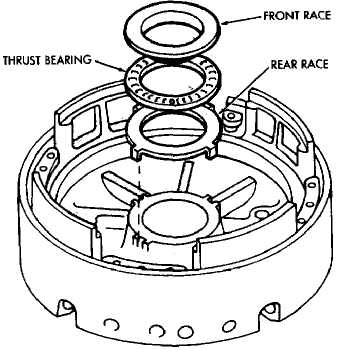

Remove thrust bearing and race assembly from

clutch drum (Fig. 4).

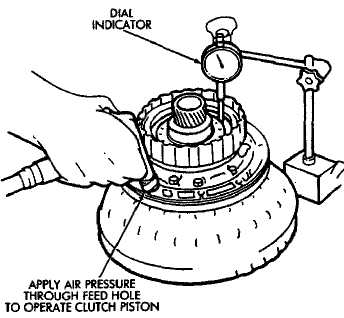

Measure stroke length of clutch piston as follows:

(a) Mount oil pump on torque converter. Then mount clutch on oil pump (Fig. 5).

(b) Mount dial indicator on clutch and position

indicator stylus on clutch piston (Fig. 6).

(c) Apply compressed air through clutch feed hole

in oil pump and note piston stroke length. Stroke

length should be 1.85 to 2.15 mm (.0728 to .0846 in).

Replace clutch pack retainer if stroke length is

incorrect.Refer to chart in Specifications section for re

placement retainer thicknesses.

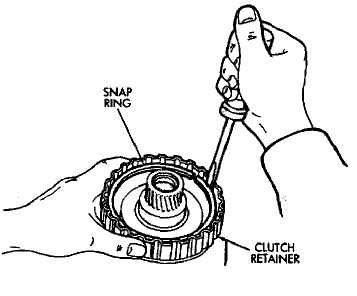

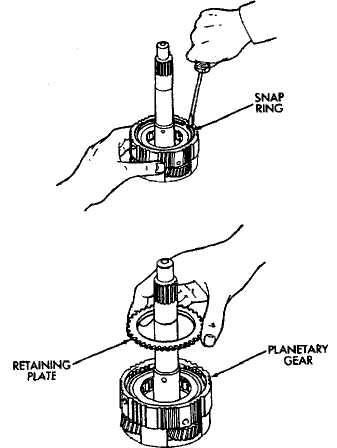

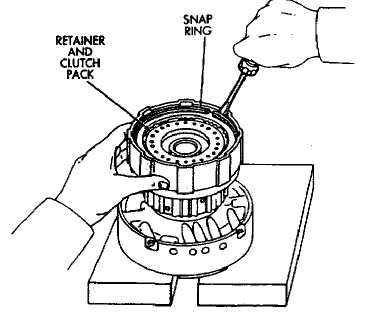

Remove clutch pack snap ring and remove the

clutch pack.

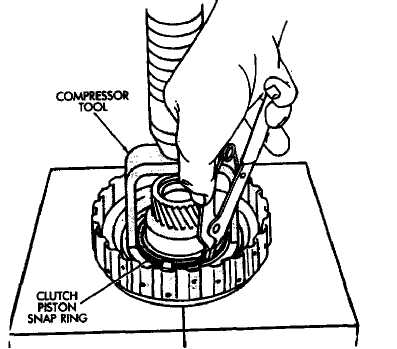

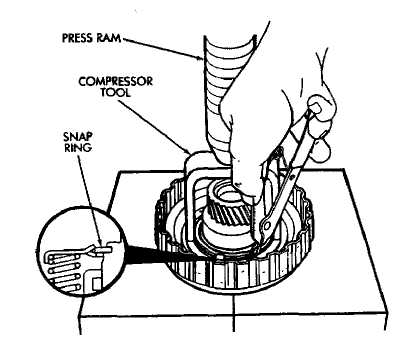

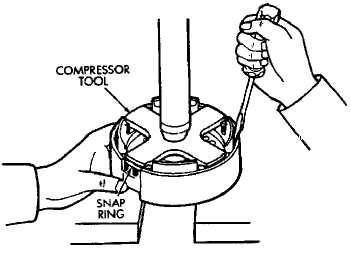

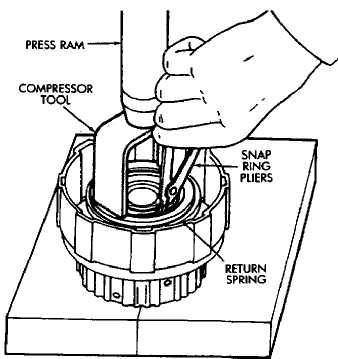

Compress piston return spring with tool B.Vi. FM.

27 and shop press and remove piston snap ring (Fig. 8).

Remove compressor tool and piston return springs.

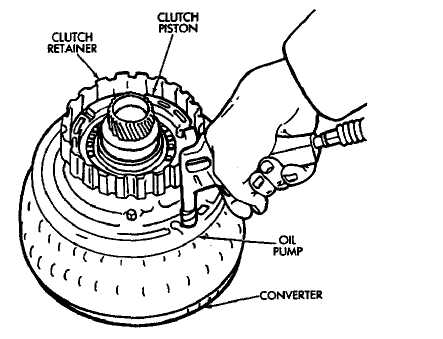

Mount oil pump on converter. Then mount clutch

on oil pump (Fig. 9).

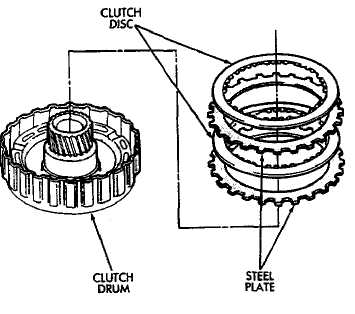

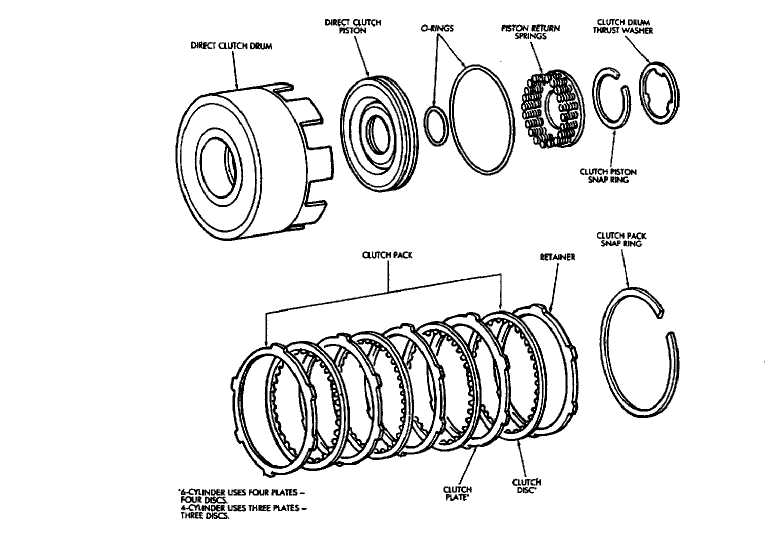

Fig. 1 Overdrive Planetary Gear And Clutch Components

Hold clutch piston by hand and apply compressed

air through oil pump feed hole to ease piston out (Fig.

9). Apply only enough air pressure to remove piston.

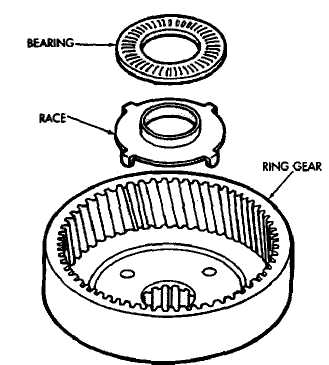

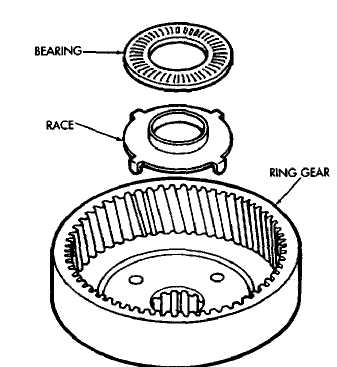

Remove bearing and race from ring gear (Fig. 10).

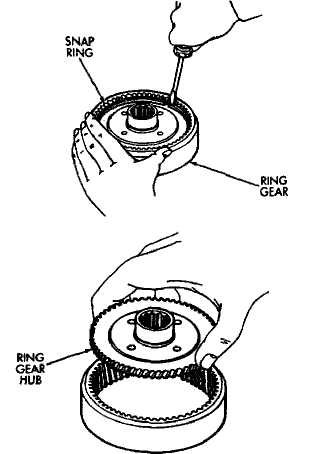

Remove snap ring from ring gear and remove ring

gear hub (Fig. 11).

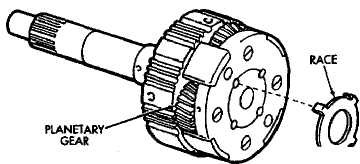

Remove race from planetary gear (Fig. 12).

Remove snap ring and remove retaining plate

(Tig. 13).

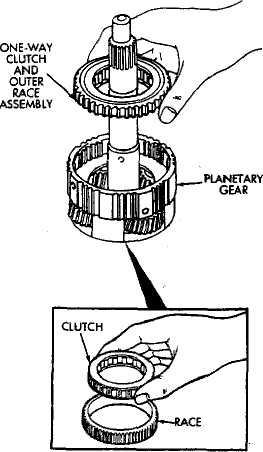

Remove one-way clutch and outer race as assem

bly. Then separate race from clutch (Fig. 14).

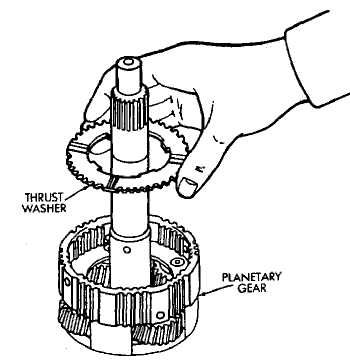

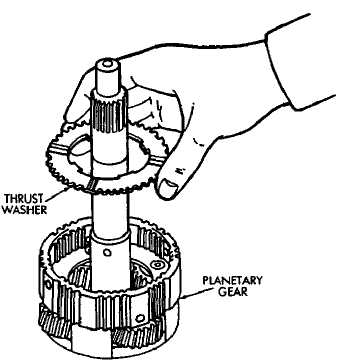

Remove thrust washer (Fig. IS).

Measure clutch disc thickness. Minimum allow

able thickness is 1.84 mm (.0724 in).

CLUTCH DRUM

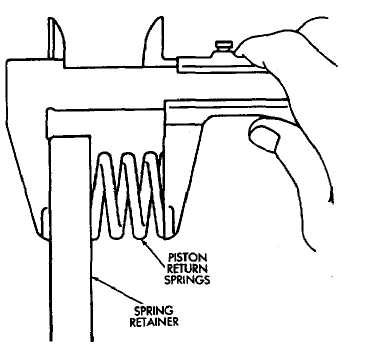

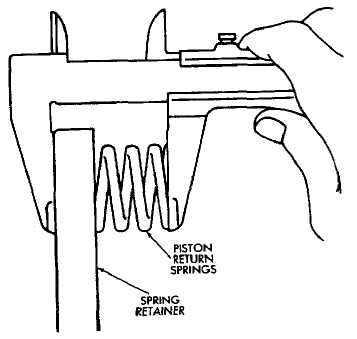

Measure free length of piston return springs with

springs in retainer (Fig. 16>. Length should be 16.8 mm

(.661 in).

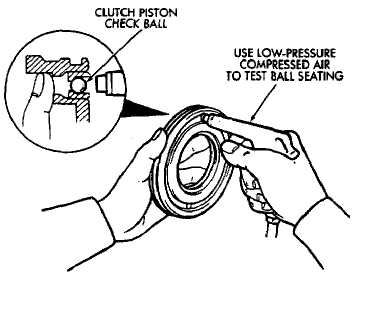

Check clutch piston check ball (Fig. 17). Shake

piston to see if ball moves freely. Then check ball seal

ing by applying low pressure compressed air to ball inlet

as shown. Air should not leak past check ball.

Check inside diameter of clutch drum bushings

with bore gauge (Fig. 18). Maximum inside diameter is

27.11 mm (1.0673 in). Replace drum if bushing inside

diameter is greater than specified.

Fig. 4 Removing Clutch Drum Bearing And Race

Fig. 2 Checking One-Way Clutch

Fig. 3 Removing Overdrive Clutch From Gear

Fig. 5 Assembling Converter, Pump And Clutch For T

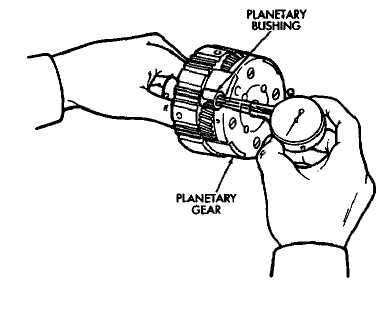

(21) Check inside diameter of planetary gear bushing (Fig, 19). Maximum inside diameter is 11.27 rom (0.4437 in). Replace planetary gear if bushing inside diameter is greater then specified.

Gear And Clutch Assembly

Install thrust washer in planetary gear (Fig. 20).

Grooved side of washer faces up and toward front.

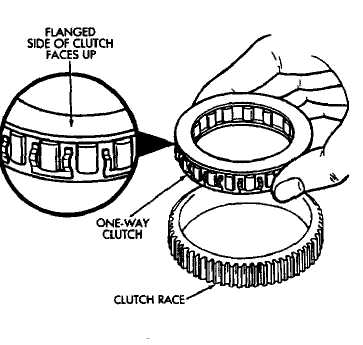

Install one-way clutch in race (Fig. 21). Flanged

side of clutch must face upward as shown.

Install assembled one-way clutch and outer race in

planetary gear. Be sure flanged side of clutch is facing

upward.

Install clutch pack retaining plate and snap ring

in planetary gear.

Fig. 8 Removing Clutch Piston Snap Ring

Coat planetary race with petroleum jelly and in

stall it on planetary gear. Outside diameter of race is

41.8 mm (1.646 in); inside diameter is 27.1 mm (1.067

in).

Install hub in planetary ring gear and install snap

ring.

Coat race and bearing with petroleum jelly and

install in planetary ring gear (Fig. 22).

Verify bearing/race size. Outside diameter of race

is 47.8 mm (1.882 in); inside diameter is 24.2 mm (.953

in). Outside diameter of bearing is 46.8 mm (1.843 in);

inside diameter is 26 mm (1.024 in).

Fig. 6 Checking Overdrive Clutch Piston Stroke

Fig. 9 Removing Overdrive Clutch Piston

Fig. 7 Removing Clutch Pack Snap Ring 46 Fig. 9 Removing Overdrive Clutch Piston(9) Lubricate and install new O-rings on clutch piston.

Then install piston in clutch drum.

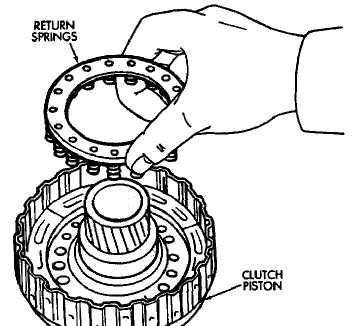

(10) Install piston return springs in clutch piston (Fig.

23).

Install piston snap ring. Compress piston return

springs with compressor tool and shop press (Fig. 24).

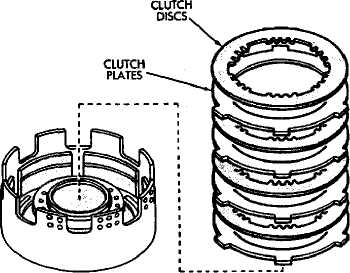

Install clutch pack in drum. Install steel plate

first, then a disc (Fig. 25). Continue installation se

quence until required number of discs and plates have

been installed.

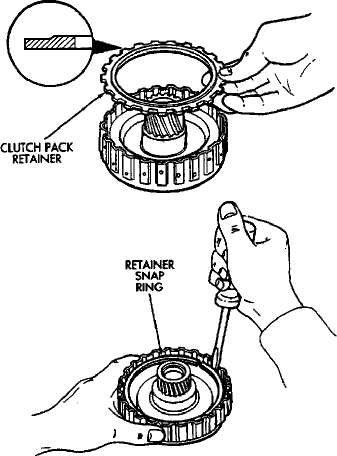

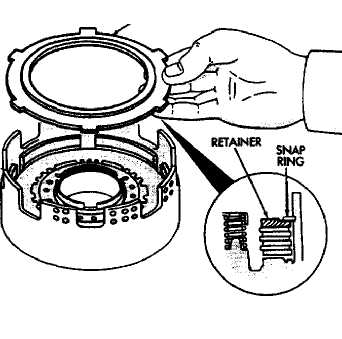

Install clutch pack retainer with flat side facing

downward. Then install retainer snap ring (Fig. 26).

Compress springs with tool B.Vi. FM. 27.

Measure clutch piston stroke length again (refer

to procedure outlined in disassembly procedure ). If

stroke length is incorrect, install new clutch discs or

select fit retainer. Retainer thicknesses are outlined in

the Specifications section.

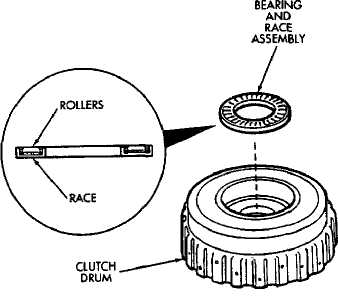

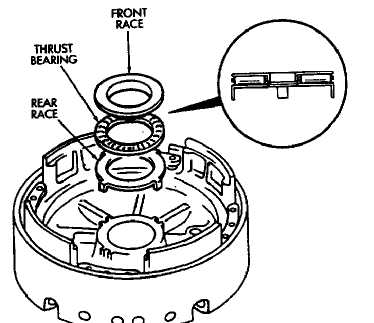

Install clutch drum bearing and race assembly

(Fig. 27). Be sure bearing rollers face upward as shown.

Fig. 10 Removing Ring Gear Bearing And Race

Fig. 12 Remove Planetary Gear Race

Fig. 11 Removing Ring Gear Hub

Fig. 13 Removing Snap Ring And Retaining Plate

Outside diameter of assembled bearing and race is 50.2 mm (1.976 in). Inside diameter is 28.9 mm (1.138 in). (16) Install clutch on planetary gear.

(17) Verify one-way clutch operation. Hold drum and turn planetary shaft clockwise and counterclockwise. Shaft should turn clockwise freely but lock when turned counterclockwise.

Fig. 14 Removing One-Way Clutch

Fig. 16 Checking Piston Return Spring Length

Fig. 17 Testing Clutch Piston Check Ball

Fig. 15 Removing Planetary Thrust Washer

Fig. 18 Checking Clutch Drum Bushings

Fig. 19 Checking Planetary Bushing

Fig. 20 Install Planetary Thrust Washer

Fig. 21 Assembling One-Way Clutch And Race

Fig. 24 Installing Clutch Piston Snap Ring

Fig. 22 Install Ring Gear Bearing And Race

Fig. 22 Install Ring Gear Bearing And Race

Fig. 23 Installing Piston Return Springs

Fig. 25 Installing Clutch Discs And Plates

Fig. 27 Installing Clutch Drum Bearing And Race Assembly

Fig. 26 Installing Retainer And Snap Ring

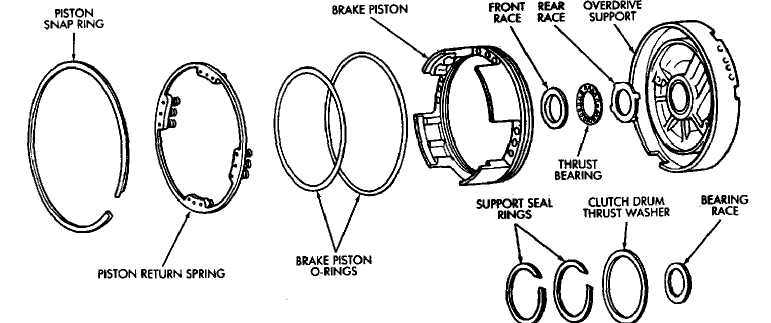

OVERDRIVE SUPPORT OVERHAUL

Support Disassembly

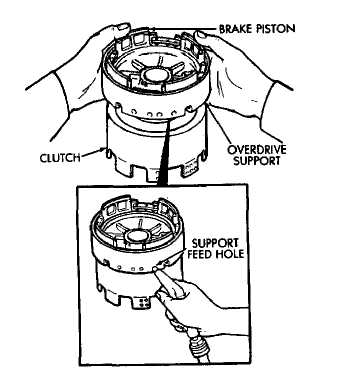

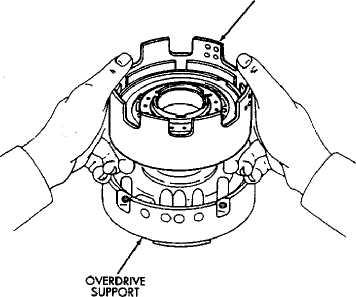

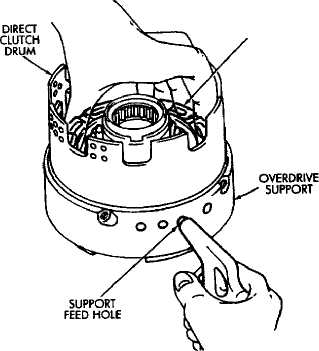

Check brake piston operation. Mount support on

clutch (Fig. 2).

Apply compressed air through support feed hole

and observe brake piston movement (Fig. 2). Piston

should move smoothly and not bind or stick. If operation

is incorrect, replace piston and support.

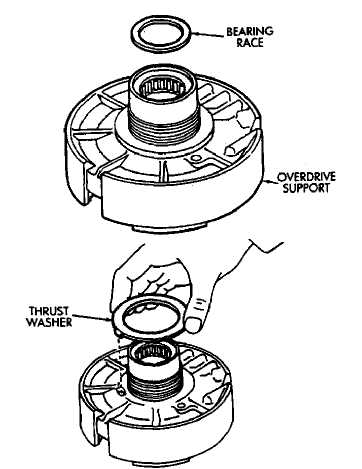

Remove thrust bearing front race, thrust bearing

and rear race (Fig. 3).

Turn overdrive support over and remove bearing

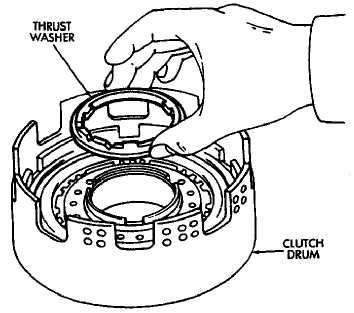

race and clutch drum thrust washer (Fig. 4).

Compress piston return spring with tool B.Vi. FM.

26 and remove piston snap ring (Fig. 5).

Mount support in direct clutch and remove brake

piston with compressed air. Apply air to same feed hole

used when checking piston operation.

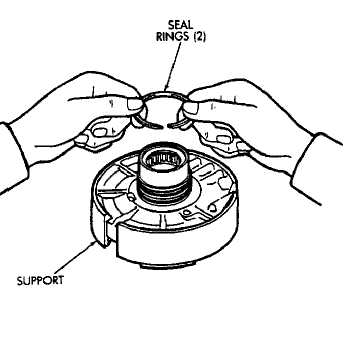

Remove and discard support O-rings (Fig. 1).

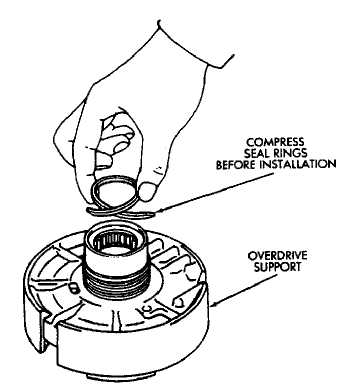

Remove support seal rings (Fig. 6).

Fig. 1 Overdrive Support Components

Fig. 1 Overdrive Support Components

Fig. 2 Checking Brake Piston Movement

Fig. 3 Removing Support Thrust Bearing And Races

(9) Measure free length of piston return springs with

springs mounted in retainer (Fig. 7). Length should be

18.61 mm (.733 in).

Clean support components and dry them with

compressed air.

Inspect overdrive support and brake piston. Re

place support and piston if either part is worn or dam-

Fig. 4 Removing Clutch Drum Thrust Washer And Ïàñå

Assembling Overdrive Support

Lubricate new support seal rings. Then compress

rings and install them on support {Fig. 8).

Lubricate and install new O-rings on brake piston.

Then carefully seat piston in support.

Install return springs on brake piston.

Fig. 6 Removing Support Seal Rings

Compress return springs with tool (Fig. 5) and

install piston snap ring.

Install support bearing race and clutch drum

thrust washer (Fig. 4).

Install thrust bearing and front and rear bearing

races. Thrust bearing rollers should face upward as

shown (Fig. 9).

Fig. 7 Checking Piston Return Spring Lengtn

Fig. S Removing/Installing Piston Snap Ring 53 Fig. 7 Checking Piston Return Spring Length

(7) Verify thrust bearing/race sizes (Fig. 9). Front race outer diameter is 47.8 mm (1.882 in); inside diameter is 30.7 mm (1.209 in). Rear race outer diameter is 47.8 mm

(1.882 in); inside diameter is 34.3 mm (1.350 in). Bearing outer diameter is 47.7 mm (1.878 in); inside diameter is 32.7 mm (1.287 in).

(8) Verify brake piston operation. Use same procedure described at beginning of disassembly. Piston should operate smoothly and not bind or stick.

Fig. 8 Installing Support Seal Rings

Fig. 9 Installing Support Thrust Bearing And Races

DIRECT CLUTCH OVERHAUL

Clutch Disassembly

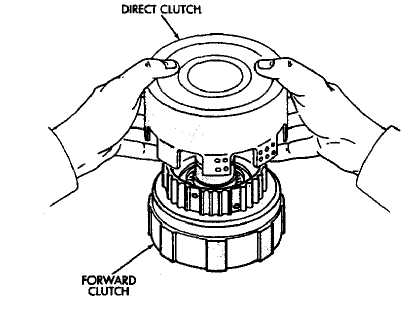

(DRemove direct clutch from forward clutch (Fig. 2). (2) Remove clutch drum thrust washer (Fig. 3).

Fig. 1 Direct Clutch Components

Fig. 3 Removing Clutch Drum Thrust Washer

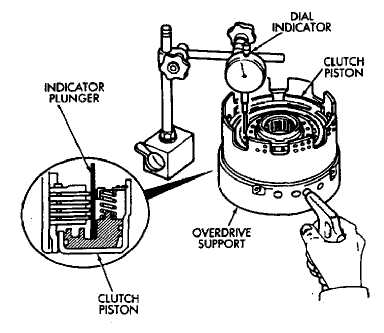

Fig. 2 Separate Direct Clutch From Forward Clutch 55 Fig. 3 Removing Clutch Drum Thrust WasherCheck clutch piston stroke length as outlined in

following steps.

Mount direct clutch on overdrive support assembly

(Fig. 41.

Mount dial indicator on clutch and position indi

cator plunger on clutch piston (Fig. 4).

Apply 57-114 psi air pressure through feed hole in

overdrive support and note piston stroke length iFig. 5).

Check stroke at least twice.

Piston stroke length should be 1.37 mm to 1.60 mm

(.0539 to .0642 in). If stroke length is incorrect, either

the clutch pack retainer or clutch discs will have to be

replaced.

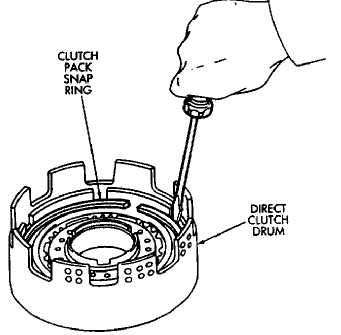

DIRECT ClUTCH

Compress clutch springs with tool B.Vi. FM. 27.

Remove clutch pack snap ring and remove retainer and

clutch pack from drum (Fig. 6).

Compress clutch piston return springs with tool

B.Vi. FM. 27 and remove clutch piston snap ring (Fig.

7).

Remove compressor tool and return spring.

Remove clutch piston. Remount clutch on over

drive support (Fig. 8). Apply compressed air through

piston feed hole in support to remove piston. Use only

enough air to ease piston out.

Fig. 4 Mount Direct Clutch On Overdrive Support

Fig. 6 Removing Clutch Pack Snap Ring

Fig. 5 Checking Direct Clutch Piston Stroke Length

Fig. 7 Removing Piston Return Spring Snap Ring

CLUTCH PISTON

Fig. 8 Removing Direct Clutch Piston

Remove and discard clutch piston O-rings.

Measure clutch disc thickness. Minimum allow

able thickness is 1.84 mm (.0724 in). Replace discs if

below minimum thickness.

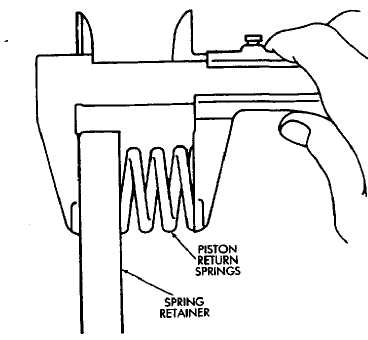

Measure free length of piston return springs with

springs in retainer (Fig. 9). Length should be 21.32 mm

(.839 in). Replace return springs if not within specifi

cation.

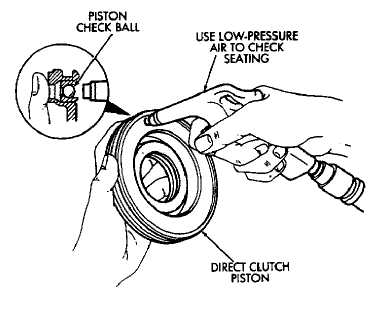

Check clutch piston check ball (Fig. 10). Shake

piston to see if ball moves freely. Then check ball seat

ing by applying low pressure compressed air to ball inlet

as shown. Air should not leak past check ball.

(16) Measure inside diameter of clutch drum bushing. Inside diameter should be no more than 53.97 mm (2.1248 in). Replace drum if bushing inside diameter is greater than specified.

Direct Clutch Assembly

Lubricate and install replacement O-rings on

clutch piston.

Install clutch piston in drum and install return

springs on piston.

Compress piston return springs and install snap

ring (Fig. 7). Be sure snap ring end gap is not aligned

with spring retainer tab.

Install clutch discs and plates (Fig. 11). Install

plate then disc until all plates and discs are installed.

Use four plates and discs in 6-cyl. transmissions and

three plates and discs in 4-cyl. transmissions.

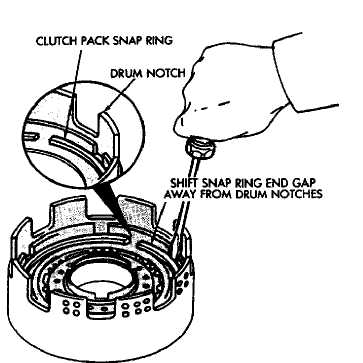

Install clutch pack retainer in drum (Fig. 12).

Install clutch pack snap ring (Fig. 12).

Check snap ring position. If necessary, shift snap

ring until end gap is not aligned with any notches in

clutch drum (Fig. 12).

Check clutch piston stroke length a second time.

If length is OK, continue with assembly. If stroke length

is incorrect, replace clutch discs or use different thick

ness clutch pack retainer (Fig. 12). See Specifications

section for retainer thicknesses.

Lubricate clutch drum thrust washer with petro

leum jelly and install it in drum (Fig. 3).

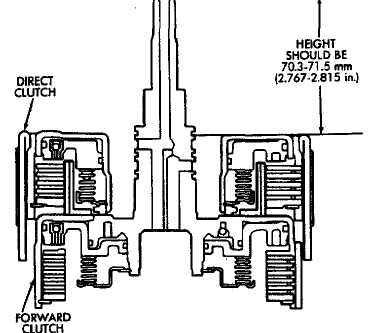

Mount direct clutch assembly on forward clutch

assembly and check assembled height (Fig. 14). Height

should be 70.3 to 71.5 mm (2.767 to 2.815 in).

If assembled height is incorrect, clutches are not

seated.

Fig. 9 Checking Piston Return Spring Length

Fig. 10 Testing Piston Check Ball Seating

(12) If clutch height is OK, remove direct clutch from forward clutch and proceed to forward clutch overhaul.

Fig. 11 Installing Direct Clutch Discs And Plates

Fig. 13 Adjusting Clutch Pack Snap Ring Position

CLUTCH PACK ’RETAINER

Fig. 12 Install Clutch Pack Retainer

Fig. 14 Checking Direct Clutch Assembled Height

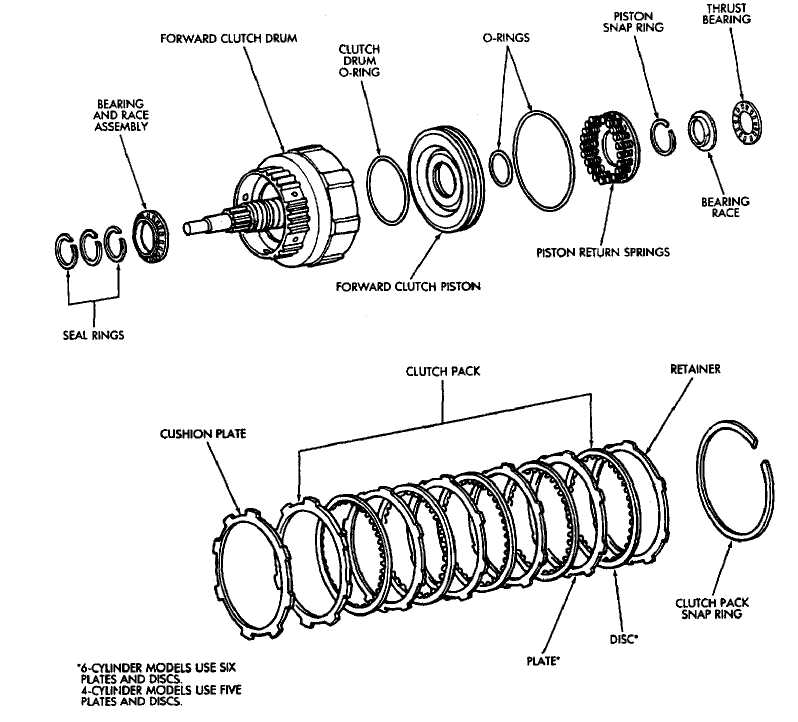

FORWARD CLUTCH OVERHAUL

Fig. 1 Forward Clutch Components

59

Forward Clutch Disassembly

(1) Check clutch piston stroke as outlined in following

steps.

Position overdrive support on wood blocks and

mount forward clutch drum on support (Fig. 2).

Remove bearing and race from forward clutch

drum (Fig. 2).

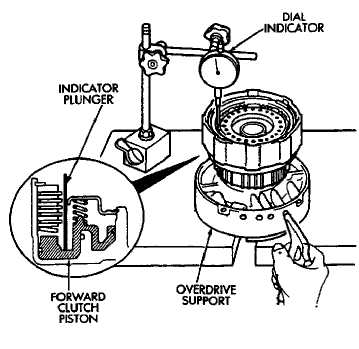

(4) Mount dial indicator on clutch drum. Position dial

indicator plunger against clutch piston (Fig. 3).

THRUST BEARING BEARING RACE

Fig. 2 Positioning Drum And Support On Wood Blocks

Apply compressed air through right side feed hole

in support and note piston stroke length on dial indi

cator.

Stroke length should be: 3.73 to 4.59 mm (.1469 to

.1807 in) on 6-cyl. transmissions and 3.42 to 4.23 mm

(.1346 to .1665 in) on 4-cyl. transmissions.

Replace clutch discs if stroke length is incorrect.

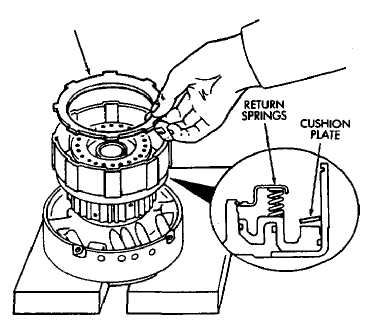

Remove clutch pack snap ring and remove retainer

and clutch pack (Fig. 4).

Remove clutch pack cushion plate (Fig. 5).

Compress clutch springs with tool B.Vi. FM. 27

and remove piston snap ring.

Remove spring compressor tool and piston return

springs.

Fig. 4 Removing Retainer And Clutch Pack

CUSHION PLATE

Fig. 3 Checking Forward Clutch Piston Stroke Length

Fig. 5 Removing Cushion Plate