A/C-HEATER SYSTEM - MANUAL

1993 Jeep Cherokee

1993 AIR CONDITIONING & HEAT

Chrysler Motors Manual A/C-Heater Systems

Jeep; Cherokee & Wrangler A/C SYSTEMS SPECIFICATIONS

SPECIFICATIONS TABLE

Application Specification

Compressor Type Sanden SD-709 7-Cyl.

Compressor Belt Tension

Serpentine Belt

New 180-200 lbs. (82-91 kg)

Used 140-160 lbs. (64-73 kg)

System Oil Capacity 4.6 ozs.

Refrigerant (R-12) Capacity

Cherokee 38.0 ozs.

Wrangler 32.0 ozs.

System Operating Pressures

High Side 160-235 psi (11.2-16.5 kg/cm)

Low Side 30-35 psi (2.1-2.5 kg/cm)

DESCRIPTION & OPERATION

A/C-HEATER SYSTEM

Cherokee

The A/C clutch relay controls voltage supply to the

compressor clutch. Electronic Control Unit (ECU) energizes the A/C clutch relay. ECU will not energize relay if evaporator temperature is too low, or if the refrigerant system pressure is too low.

ECU monitors evaporator temperature based upon the voltage reference it receives from the A/C sensor (evaporator thermistor) in the evaporator housing. ECU monitors refrigerant pressure through low pressure switch on receiver-drier. If refrigerant pressure is less than 28 psi (2.0 kg/cm), the low pressure switch contacts open. ECU then stops compressor operation to prevent damaging the compressor.

NOTE: ECU may delay compressor clutch engagement for as many as 30 seconds.

Wrangler

The A/C clutch relay controls voltage supply to the

compressor clutch. Electronic Control Unit (ECU) energizes the A/C clutch relay. ECU will not energize relay if evaporator temperature is too low, or if the refrigerant system pressure is too low.

If the switch contacts in the A/C thermostat are open

(indicating evaporator temperature is too low), or if the low pressure switch contacts are open (indicating refrigerant system pressure is too low), the ECU will not energize the A/C clutch relay. A/C thermostat (temperature control thermostat) is in evaporator housing. Low pressure switch is on receiver-drier. System uses a 3-speed blower motor instead of a blower resistor.

CONTROL PANEL

Cherokee

The mode control lever (upper lever) operates a vacuum switch on the back of the control panel. The vacuum switch controls vacuum to defroster, floor, panel and fresh/recirculated air vacuum motors, as well as a vacuum-actuated heater control valve (water valve). The heater control valve closes when vacuum is applied to it.

The A/C switch is closed when the lever is in any of the A/C modes (MAX, NORM or BI-LEVEL). The temperature control lever (lower lever) moves a cable that controls the position of the blend-air door in the heater case.

Wrangler

The mode control lever (upper lever) moves 2 cables, one for the vent doors and one for the defrost/floor duct door. Lever also operates a vacuum switch on back of control panel.

The vacuum switch allows or denies vacuum to the fresh air door vacuum motor. The temperature control lever (lower lever) moves a cable that controls the position of the blend-air door in the heater case.

NOTE: System does not use a heater control valve (water valve). Coolant always flows through the heater core.

TROUBLE SHOOTING

INSUFFICIENT OR NO COOL AIR

Check

blower motor operation. If blower motor operates, go

to next

step. If blower motor does not operate, check fuse. If fuse

is

blown, replace fuse. If fuse is

okay, apply battery voltage directly

to blower motor. If blower

motor does not operate, replace blower

motor. If blower motor

operates, replace blower switch or repair wire

harness.

Ensure

airflow is correct. If airflow is not correct,

check

for correct operation of air distribution doors and for

obstructions

in vent channels. If airflow is correct, ensure

compressor clutch

is operating and drive belt is tightened to

specification.

Go to step 4).

If

compressor clutch does not operate, check for battery

voltage at

compressor clutch connector. If voltage is present, replace

the

clutch. If voltage is not present, perform COMPRESSOR CLUTCH

CIRCUIT

test under TESTING.

Check

refrigerant system for proper charge. Evacuate and

charge system

if necessary. Check pressure switch and replace if

necessary.

Check A/C sensor (Cherokee) or A/C thermostat (Wrangler)

and

replace if necessary. Check expansion valve and replace

if

necessary.

TESTING

A/C CLUTCH RELAY

Cherokee

A/C clutch

relay is in engine compartment, in power

distribution center.

With engine at idle and MAX or NORM position

selected, check

voltage at Dark Blue/White wire of relay connector.

If voltage

is not present, check for open Dark Blue/White

wire or blown fuse

F6 in power distribution center. If voltage is

present, ground

the Dark Blue/Orange wire at relay. If clutch engages,

relay is

okay. If clutch does not engage, replace relay.

BLOWER MOTOR

Using an

ohmmeter, check resistance between blower motor

housing and

chassis ground. Zero ohms should be present. If resistance

is

zero, go to next step. If resistance is more than zero ohms,

repair

ground connection.

Disconnect

blower motor connector. Apply battery voltage

to blower motor

connector. Replace motor if it does not operate

smoothly at high

speed.

BLOWER MOTOR CIRCUIT

Wrangler

Turn

ignition on. Check voltage at ignition switch side of

fuse

No. 12. If no voltage is present, repair

open in Black/Orange

wire between fuse No. 12 and

ignition switch. If battery voltage is

present, check voltage on

other side of fuse.

If

battery voltage is not present, replace fuse. If

battery voltage

is present, check voltage at White wire terminal of

blower

switch. If battery voltage is present, go to next step. If

battery

voltage is not present, repair open White wire circuit between

fuse

No. 12 and blower switch.

With

blower switch in LO position, check voltage at Dark

Blue wire

terminal of blower switch connector. If battery voltage is

not

present, replace blower switch. If battery voltage is present, go

to

next step.

With

blower switch in MED position, check voltage at Green

wire

terminal. If battery voltage is not present, replace blower

switch.

If battery voltage is present, go to next step.

With

blower switch in HI position, check voltage at Orange

wire

terminal. If battery voltage is not present, replace blower

switch.

If battery voltage is present, go to next step.

Turn

ignition off. Check resistance between blower motor

housing and

chassis ground. If resistance is not zero ohms, repair

ground

wire between blower motor and ground. If resistance is zero

ohms,

go to next step.

Turn

ignition on. With blower switch in LO position, check

voltage at

Dark Blue wire terminal of blower motor connector. If

battery

voltage is present, go to next step. If battery voltage is

not

present, repair Dark Blue wire between blower switch and

blower motor.

With

blower switch in MED position, check voltage at Green

wire

terminal. If battery voltage is present, go to next step. If

battery

voltage is not present, repair Green wire between blower

switch

and blower motor.

With

blower switch in HI position, check voltage at Orange

wire

terminal. If battery voltage is present, blower motor circuit

is

okay. If battery voltage is not present, repair Orange wire

between

blower switch and blower motor.

NOTE: If blower motor fails to operate, and battery voltage was present at Dark Blue, Green and Orange wires, replace blower motor.

COMPRESSOR CLUTCH CIRCUIT

Cherokee

Apply

battery voltage to compressor clutch connector

terminal. If

clutch engages, go to next step. If clutch does not

engage,

connect a jumper wire between clutch coil frame and chassis

ground.

If clutch engages, repair clutch coil ground circuit. If

clutch

does not engage, replace clutch coil.

Turn ignition and blower switch on. Set control lever to

MAX or NORM position. Check voltage at Light Green wire terminal of low pressure switch connector. If battery voltage is not present, repair circuit between low pressure switch and control panel.

If battery

voltage is present, check voltage at Dark

Blue/Orange wire

terminal of low pressure switch connector. If battery

voltage is

present, go to next step. If battery voltage is not

present,

check refrigerant system charge. Recharge system if

undercharged.

If refrigerant system charge is okay, replace low

pressure

switch.

Start

engine. Check voltage at Dark Blue/Black wire

terminal

of A/C clutch relay connector. If battery voltage is not

present,

check fuse No. 6 in engine compartment

fuse block. Replace

fuse if blown. If battery voltage is present,

connect a jumper wire

between ground

and Dark Blue/Orange wire terminal of A/C clutch relay

connector.

If clutch does not engage, check wiring to ECU.

Wrangler

Apply

battery voltage to compressor clutch connector

terminal. If

clutch engages, go to next step. If clutch does not

engage,

connect a jumper wire between clutch coil frame and chassis

ground.

If clutch engages, repair clutch coil ground circuit. If

clutch

does not engage, replace clutch coil.

Turn

ignition and blower switch on. Set control lever to

MAX position.

Check voltage at Light Blue/Black wire terminal of low

pressure

switch connector. If battery voltage is not present, go to

step

4). If battery voltage is present, check

continuity between low

pressure switch

terminals.

If there

is continuity, repair open Light Blue/Red wire

circuit between

low pressure switch and ECU. If there is no

continuity, check

refrigerant system charge. Recharge system if

undercharged. If

system charge is okay, replace low pressure switch.

NOTE: Both wire terminals at the A/C thermostat connector are

Light Blue. It will be necessary to determine which wire is the circuit from the blower switch.

Check

voltage at Light Blue wire terminal of A/C

thermostat connector

(wire that leads to A/C blower switch). See

WIRING

DIAGRAMS. If battery voltage is not present, repair open Light

Blue

wire circuit between A/C thermostat and blower switch.

If

battery voltage is present, check voltage at other

Light

Blue wire of A/C thermostat. If battery voltage is not

present,

replace A/C thermostat. If

battery voltage is present, repair open

Light Blue/Black wire

circuit between low pressure switch and A/C

thermostat.

REMOVAL & INSTALLATION

A/C SENSOR

Removal & Installation (Cherokee)

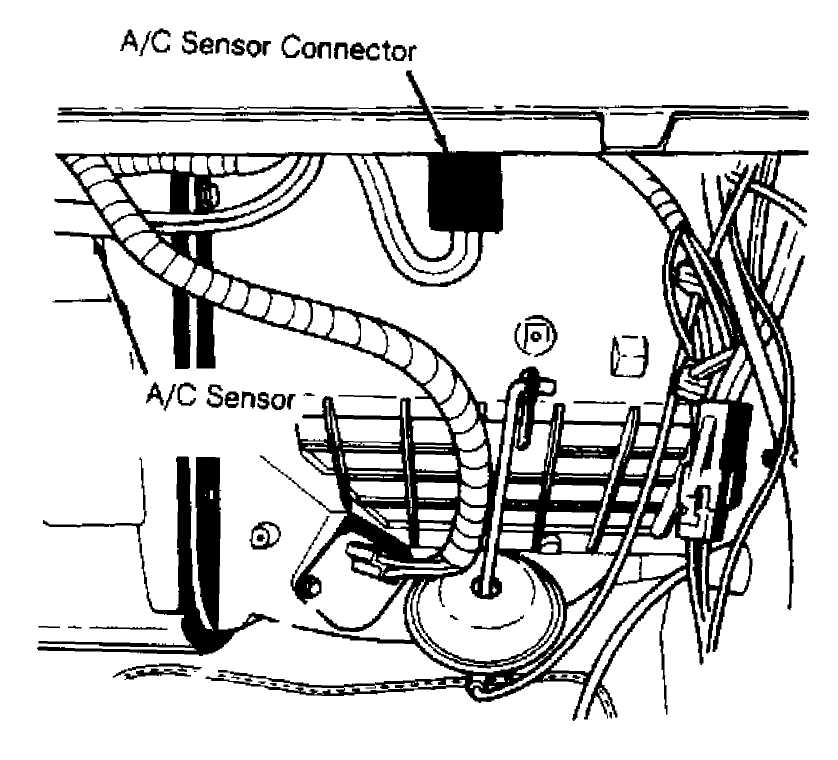

Disconnect negative battery cable. Remove center console (if equipped). Remove lower instrument panel. Disconnect A/C sensor connector. See Fig. 1. Carefully remove A/C sensor and capillary tube from hole in housing. Avoid bending capillary tube. To install, reverse removal procedure.

Fig. 1: Locating A/C Sensor (Cherokee) Courtesy of Chrysler Corp.

A/C THERMOSTAT

Removal (Wrangler)

═╧╥7╬╥.╥„ Remove evaporator housing. See EVAPORATOR & EVAPORATOR HOUSING under REMOVAL & INSTALLATION. Remove screws holding top and A/C ?hermostSt S°usi??: Separate housing halves. Carefully remove A/C thermostat and capillary tube. Avoid bending capillary tube.

Installation

Insert capillary tube into evaporator core at least 2" (51 mm), and about 2.5" (64 mm) from top of evaporator. See Fig. 2 116™0^^ T° complete installation, reverse removal F

Fig. 2: Positioning Capillary Tube In Evaporator (Wrangler) (Cross-Sectional View Shown) Courtesy of Chrysler Corp.

COMPRESSOR

NOTE: System charge can be retained by isolating compressor from rest of system. This eliminates the need to evacuate and recharge system after installation. To isolate compressor, begin removal procedure at step 1). If fully discharging system, begin at step 3).

Removal

Connect

service gauges. Close both valves on gauge. Set

both service

valves to mid-position. Start engine. Turn on A/C. Slowly

turn

low-side service valve clockwise toward front-seated position.

When

low-side pressure is zero, stop the engine, turn off

the A/C and

quickly front-seat the low-side service valve. Front-seat

the

high-side service valve. Loosen the oil level check plug on

the

compressor to release any pressure in the compressor.

Disconnect

negative battery cable. Disconnect clutch

connector.

Discharge A/C system using approved refrigerant

recovery/recycling

equipment (if compressor was not isolated).

With hoses

attached to service valves, remove service

valves from

compressor. Remove drive belt. Remove compressor bolts

and

compressor.

Installation

To

install, reverse removal procedure. If system was fully

discharged,

evacuate and charge system. If compressor was isolated

before

removal, air must be purged from compressor after service valve

and

hose assemblies are reconnected to compressor.

To purge

air, cap the service gauge ports on both service

valves. Turn

low-side service valve counterclockwise until it stops

(back-seated). This allows refrigerant to enter compressor. Set high-side service valve to mid-position.

3) Loosen

gauge port cap on high-side service valve to allow

refrigerant to

purge air from the compressor. Back-seat high-side

service

valve, and then tighten gauge port cap. Air is now purged

from

compressor.

CONDENSER

Removal (Cherokee - 2.5L)

Drain

coolant from radiator. Disconnect fan shroud and

radiator hoses.

Disconnect automatic transmission cooler lines (if

equipped).

Discharge A/C system using approved

refrigerant

recovery/recycling

equipment.

Disconnect

refrigerant hoses from condenser. Disconnect

low pressure switch

connector from switch on receiver-drier. Remove

radiator,

condenser and receiver-drier as an assembly. Separate

condenser

from radiator. Remove receiver-drier from condenser.

Installation

To install, reverse removal procedure. Add one ounce of refrigerant oil to system if replacing condenser. Fill cooling system. Evacuate and charge system.

Removal & Installation (Cherokee - 4.0L)

Remove

cooling fan shroud and cooling fan. Remove upper

crossmember and

bracket. Discharge A/C system using approved

refrigerant

recovery/recycling equipment. Disconnect A/C hoses from

condenser

and plug openings. Disconnect and separate condenser from

radiator.

Remove condenser.

To

install, reverse removal procedure. Add one ounce of

refrigerant

oil to system if replacing condenser. Fill cooling system.

Evacuate

and charge system.

Removal & Installation (Wrangler)

1) Discharge A/C system using approved refrigerant

recovery/recycling equipment. Drain cooling system. Remove cooling fan shroud and radiator. Disconnect liquid line from condenser. Remove condenser screws. Tilt bottom of condenser toward engine.

2) From

under vehicle, disconnect evaporator to receiver-

drier

hose from receiver-drier. Remove receiver-drier and condenser as

an

assembly. Remove receiver-drier from condenser. To install,

reverse

removal procedure. Fill cooling

system. Evacuate and charge system.

CONTROL PANEL

Removal & Installation

Disconnect

negative battery cable. Remove screws from

instrument panel

bezel. Remove bezel. Remove radio (if equipped).

Remove

control panel screws. Pull out control panel and

disconnect

vacuum hoses, wires and cables. Note locations for

installation

reference. Remove control panel. To install, reverse

removal

procedure.

RECEIVER-DRIER

Removal & Installation (Cherokee)

On 2.5L, remove condenser and receiver-drier as an assembly. See CONDENSER under REMOVAL & INSTALLATION. On 4.0L, discharge A/C system using approved refrigerant recovery/recycling equipment. Disconnect low pressure switch connector. Remove receiver-drier. To install, reverse removal procedure. Evacuate and charge system.

Removal & Installation (Wrangler) Discharge A/C system using approved refrigerant

recovery/recycling equipment. Disconnect refrigerant lines from receiver-drier. Remove receiver-drier. To install, reverse removal procedure. Evacuate and charge system.

EVAPORATOR & EVAPORATOR HOUSING

Removal & Installation (Cherokee)

Disconnect

negative battery cable. Discharge A/C system

using approved

refrigerant recovery/recycling equipment. Disconnect

blower motor

connector and vent tube.

Remove

console (if equipped). Remove lower

instrument

panel. Disconnect electrical connectors from blower

motor resistor and

A/C sensor. Disconnect vacuum hose at vacuum

motor. Cut plastic strap

holding evaporator housing to heater

core housing.

Disconnect

blend-air door control cable. Detach clip at

rear of blower

housing flange, and remove housing screws. Remove

housing nuts

from studs on engine compartment side of firewall. Remove

evaporator

drain tube.

Remove

right kick panel. Remove instrument panel support

bolt. Gently

pull on right side of instrument panel, then rotate

housing

downward and toward rear of vehicle to disengage housing studs

from

firewall.

Remove

evaporator housing. Disassemble evaporator housing

and remove

evaporator. To install, reverse removal procedure. Evacuate

and

charge system.

Removal & Installation (Wrangler)

1) Discharge A/C system using approved refrigerant

recovery/recycling equipment. Disconnect low-side refrigerant hose from compressor. Disconnect high-side refrigerant hose from receiver-drier.

2) Remove

evaporator housing-to-instrument panel screws and

bracket. Lower

evaporator housing, and pull hoses and grommet through

opening.

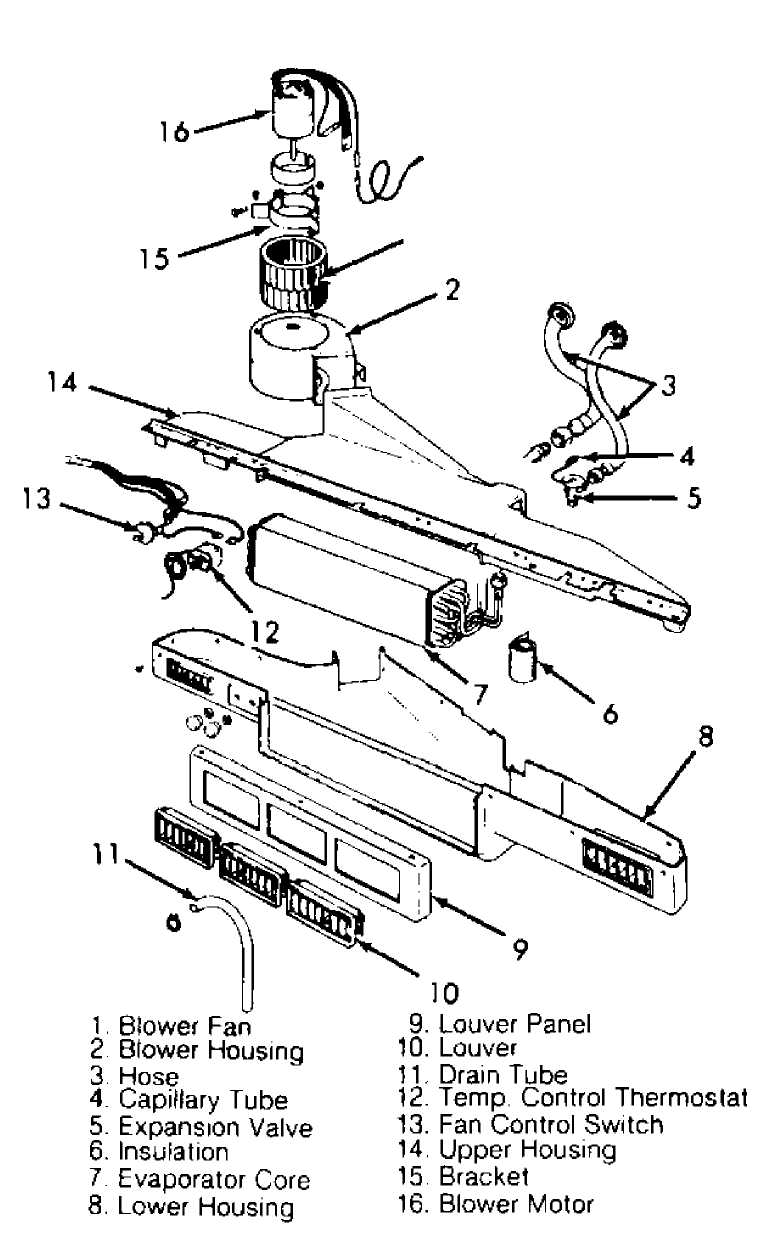

See Fig. 3. Disassemble evaporator housing

and remove

evaporator. To install,

reverse removal procedure. Evacuate and charge

system.

Fig. 3: Exploded View Of Evaporator Housing (Wrangler) Courtesy of Chrysler Corp.

EXPANSION VALVE

Removal & Installation (Cherokee) Discharge A/C system using approved refrigerant

recovery/recycling equipment. Remove coolant reservoir and bracket. Disconnect refrigerant hoses from expansion valve. Disconnect expansion valve from evaporator tubes. Remove expansion valve. To install, reverse removal procedure. Evacuate and charge system.

Removal & Installation (Wrangler) Discharge A/C system using approved refrigerant

recovery/recycling equipment. Remove evaporator housing. Remove insulation from expansion valve. See Fig. 3. Mark location of capillary tube on evaporator tubing. Disconnect refrigerant hose from expansion valve. Remove expansion valve. To install, reverse removal procedure. Evacuate and charge system.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Application Ft. Lbs. (N.m)

A/C Compressor Bolt 20 (27)

Refrigerant Hoses

Evaporator To Receiver-Drier 10 (14)

Expansion Valve To Evaporator 18 (24)

"O" Ring Fitting Type 24 (33)

Service Valve (Compressor Fitting) (1) 25 (34)

Steering Column Nut 20 (27)

(1) - Lubricate threads and "O" ring with compressor oil.

WIRING DIAGRAMS

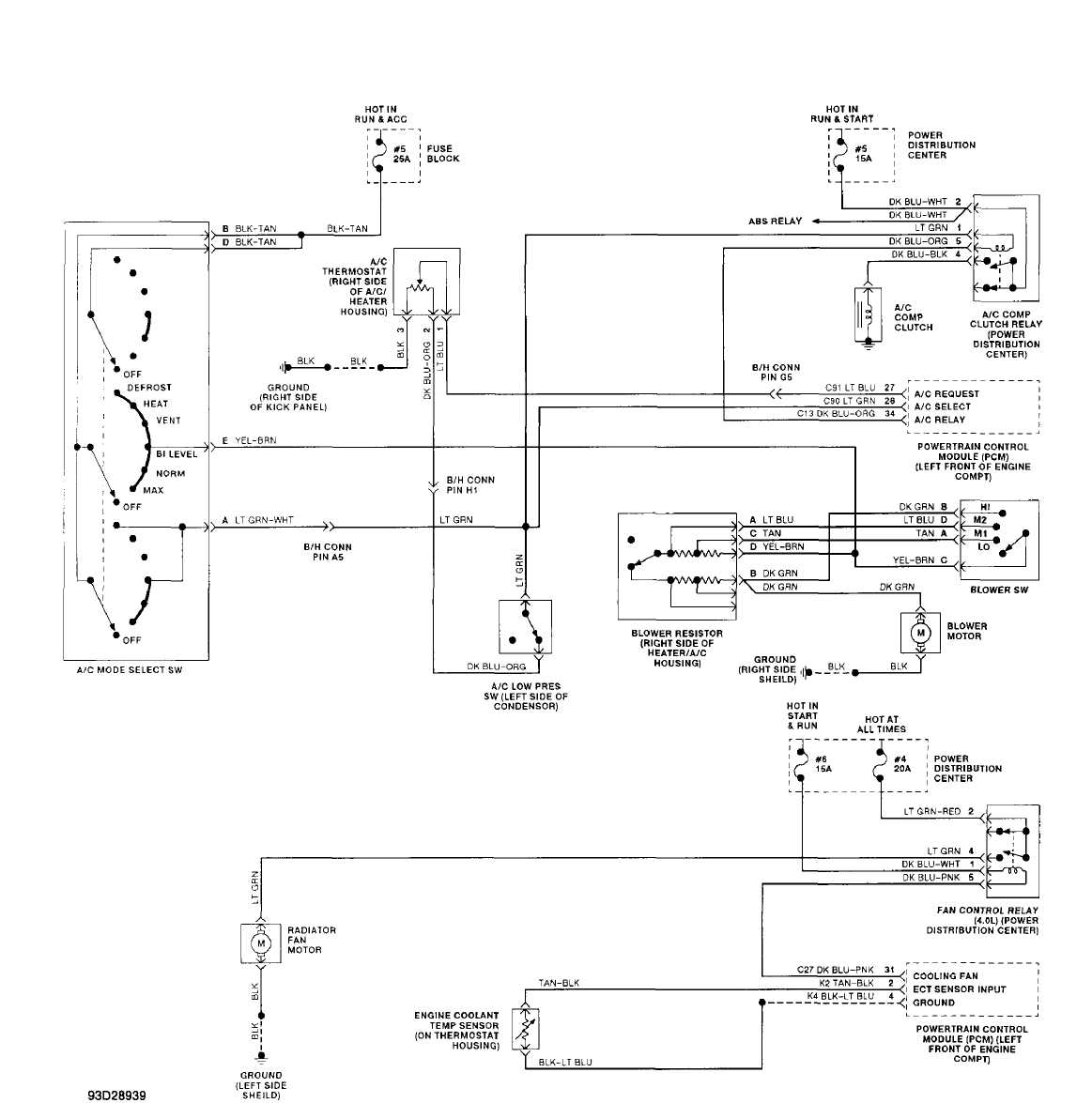

Fig. 4: Manual A/C-Heater System Wiring Diagram (Cherokee)

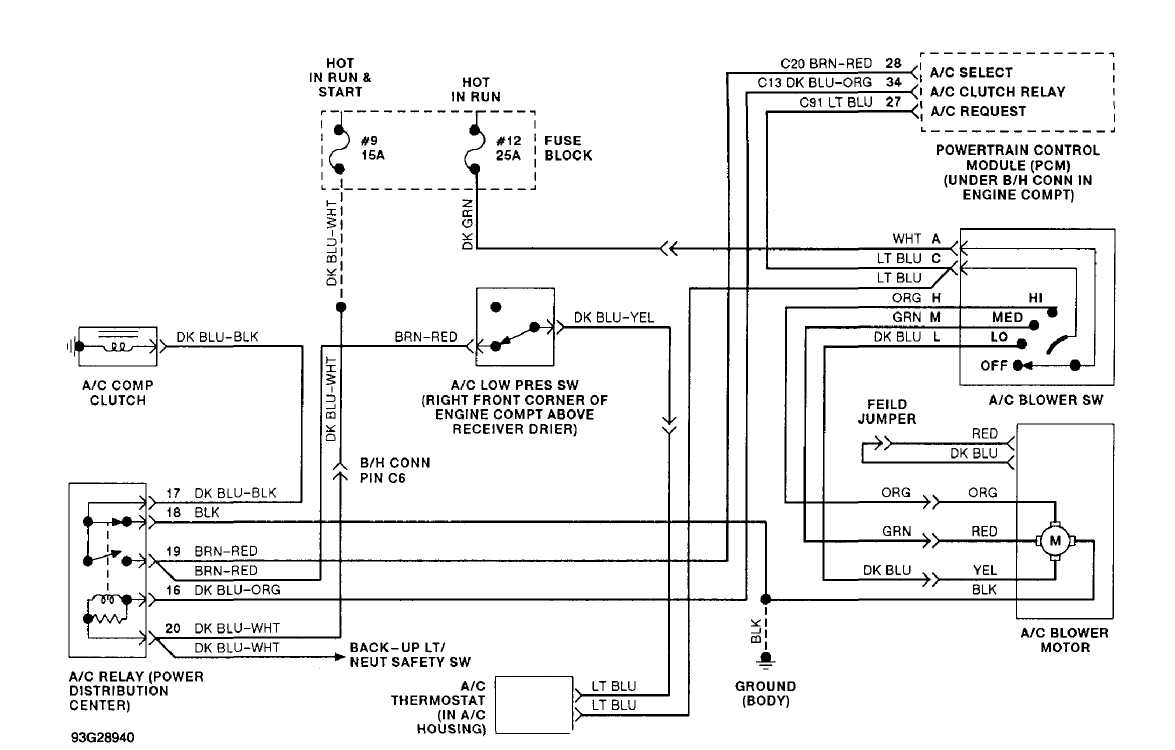

Fig. 5: Manual A/C-Heater System Wiring Diagram (Wrangler)