1993 Jeep Cherokee

GENERAL TROUBLE SHOOTING

* PLEASE READ THIS FIRST *

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

ACCESSORIES & ELECTRICAL

CHARGING SYSTEM TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC CHARGING SYSTEM TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Vehicle Will Not Dead battery Start

Loose or corroded battery connections

Ignition circuit or switch malfunction

Check battery cells, alternator belt tension and alternator output

Check all charging system connections

Check and replace as necessary

Alternator Light Loose or worn alternator Stays On With drive belt Engine Running

Loose alternator wiring connections

Short in alternator light wiring

Defective alternator stator or diodes

Defective regulator

Check alternator drive tension and condition, See Belt Adjustment in TUNE-UP article in the TUNE-UP section

Check all charging system connections

See Indicator Warning Lights in STANDARD INSTRUMENTS in the ACCESSORIES & EQUIPMENT section

See Bench Tests in ALTERNATOR article

See Regulator Check in

ALTERNATOR article

Alternator Blown fuse Light Stays Off With Ignition Switch ON

See WIRING DIAGRAMS

Defective alternator

Defective indicator light bulb or socket

See Testing in ALTERNATOR article

See Indicator Warning Lights in STANDARD INSTRUMENTS in the ACCESSORIES & EQUIPMENT section

Alternator Short in alternator wiring Light Stays OFF With Ignition Switch ON

Defective rectifier bridge

See On-Vehicle Tests in ALTERNATOR article

See Bench Tests in ALTERNATOR article

Lights or Fuses Defective alternator wiring

Burn Out

Frequently

Defective regulator

Defective battery

See On-Vehicle Tests in ALTERNATOR article

See Regulator Check in ALTERNATOR article

Check and replace as necessary

Ammeter Gauge Loose or worn drive belt Shows Discharge

Defective wiring

Check alternator drive belt tension and condition. See Belt Adjustment in TUNE-UP article in the TUNE-UP section

Check all wires and wire connections

Defective alternator or regulator

See Bench Tests and On-Vehicle Tests in ALTERNATOR article

Defective ammeter, or improper ammeter wiring connection

See Testing in STANDARD INSTRUMENTS in the ACCESSORIES & EQUIPMENT section

Noisy Alternator

Loose drive pulley

Loose mounting bolts

Worn or dirty bearings

Tighten drive pulley attaching nut

Tighten all alternator mounting bolts

See Bearing Replacement ALTERNATOR article

Defective diodes or stator

See Bench Test in ALTERNATOR article

Battery Does Stay Charged

Loose or worn drive belt

Loose or corroded battery connections

Loose alternator connections

Defective alternator or battery

Add-on electrical accessories exceeding alternator capacity

Check alternator drive belt tension and condition. See Belt Adjustment in appropriate TUNE-UP article in the TUNE-UP section

Check all charging system connections

Check all charging system connections

See On-Vehicle Tests and Bench Tests in ALTERNATOR article

Install larger alternator

Battery Overcharged-Uses Too Much Water

Defective battery

Check alternator output and repair as necessary

Defective alternator

Excessive alternator voltage

See On-Vehicle Test and Bench Tests in ALTERNATOR article

Check alternator output and repair as necessary

IGNITION SYSTEM TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

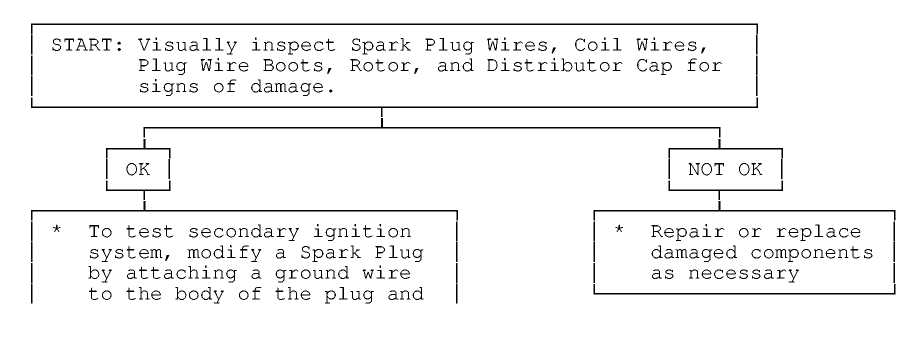

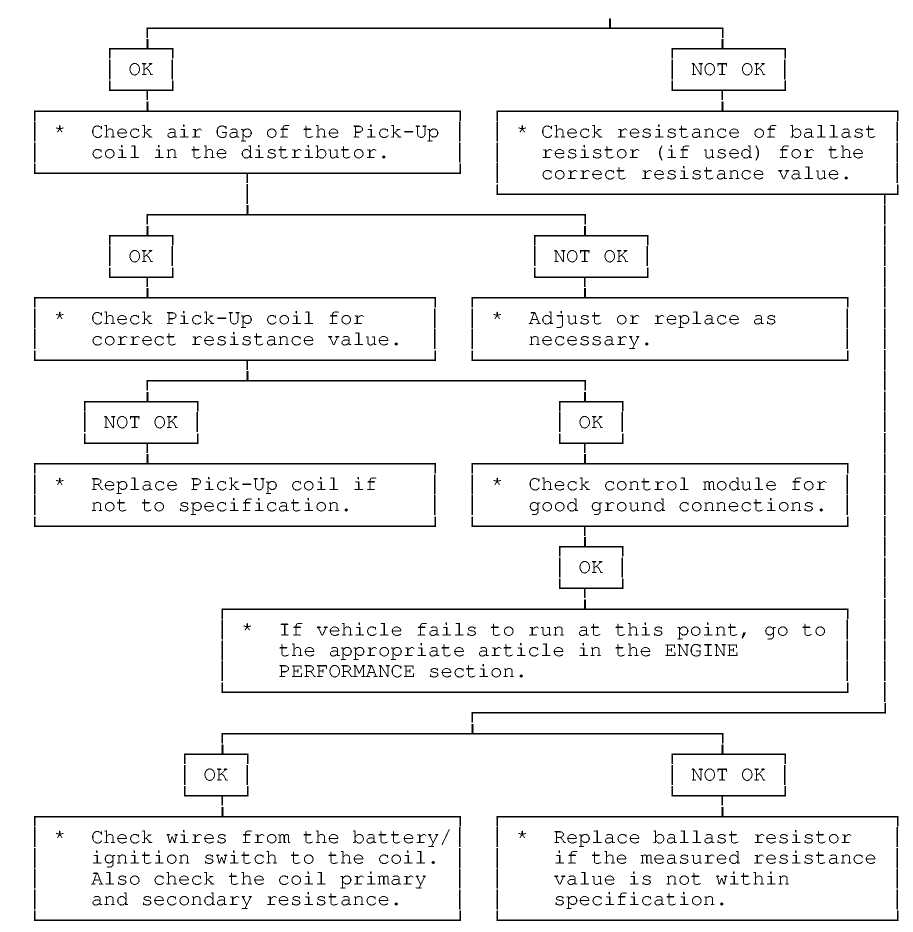

Ignition Secondary Trouble Shooting Chart

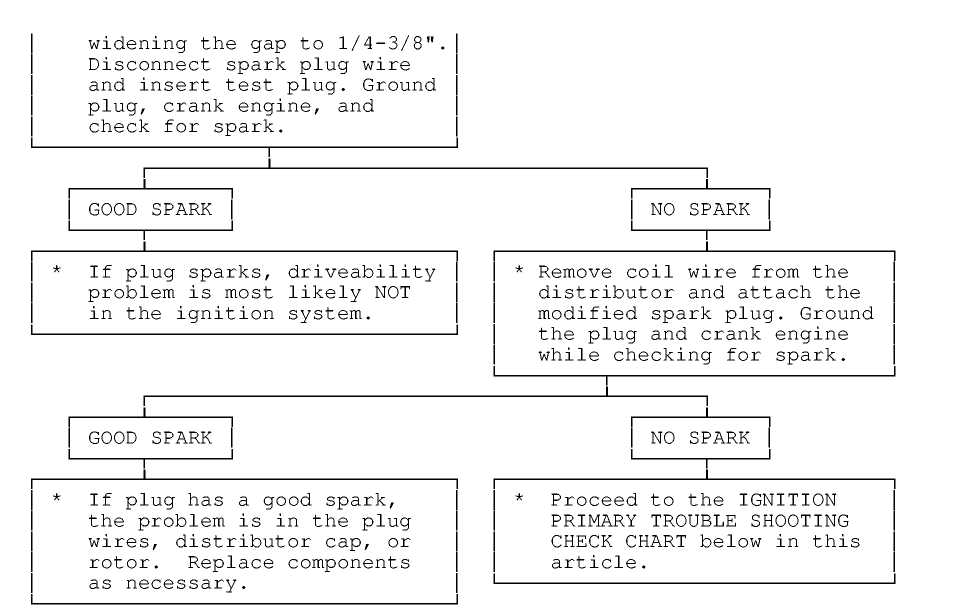

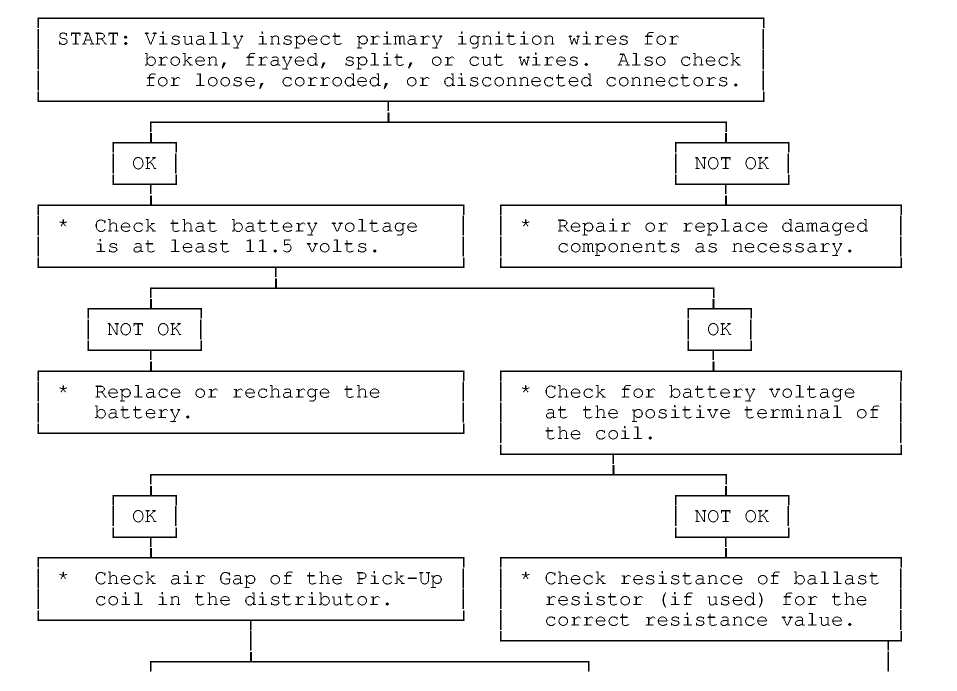

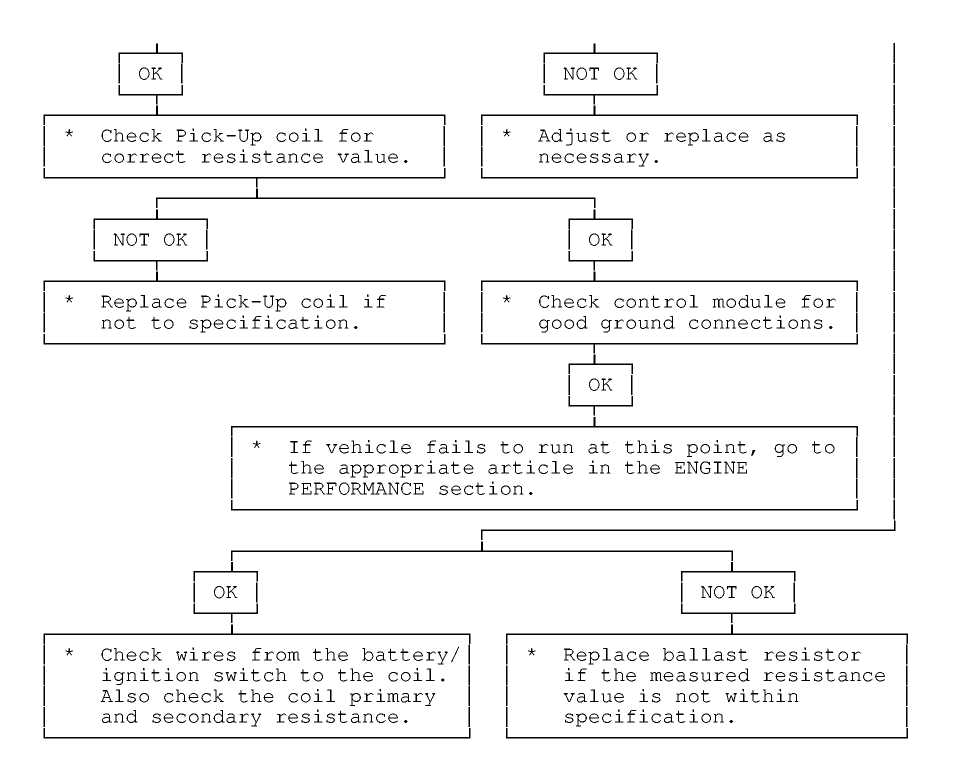

Ignition Primary Trouble Shooting Chart

STARTER TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC STARTER TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Starter Fails to Operate

Dead battery or bad connections between starter and battery

Ignition switch faulty or misadjusted

Open circuit between starter switch ignition terminal on starter relay

Starter relay or starter defective

Check battery charge and all wires and connections to starter

Adjust or replace ignition switch

Check and repair wires and connections as necessary

See Testing in STARTER article

Open solenoid pull-in wire

See Testing in STARTER article

Starter Does Not Operate and Headlights Dim

Weak battery or dead cell

Loose or corroded battery connections

Internal ground in starter windings

Grounded starter fields

Armature rubbing on pole shoes

Charge or replace battery as necessary

Check that battery connections are clean and tight

See Testing in STARTER article

See Testing in STARTERS See STARTER article

Starter clutch slipping See STARTER article

Starter Turns but Engine Does Not Rotate

Broken clutch housing

Pinion shaft rusted or dry

Engine basic timing incorrect

Broken teeth on engine flywheel

See STARTER article See STARTER article

See Ignition Timing in TUNE-UP article

Replace flywheel and check for starter pinion gear damage

Starter Will Not Crank Engine

Faulty overrunning clutch

Broken clutch housing Broken flywheel teeth

Armature shaft sheared or reduction gear teeth stripped

Weak battery

Faulty solenoid

See STARTER article

See STARTER article

Replace flywheel and check for starter pinion gear damage

See STARTER article

Charge or replace battery as necessary

See On-Vehicle Tests in STARTER article

Poor grounds

Ignition switch faulty or misadjusted

Check all ground connections for tight and clean connections

Adjust or replace ignition switch as necessary

Starter Cranks Engine Slowly

Battery weak or defective

Charge or replace battery as necessary

Engine overheated

See ENGINE COOLING SYSTEM article

Engine oil too heavy

Check that proper viscosity oil is used

Poor battery-to-starter connections

Current draw too low or too high

Bent armature, loose pole shoes screws or worn bearings

Burned solenoid contacts Faulty starter

Check that all

between

battery and starter are

clean and tight

See Bench Tests in STARTER article

See STARTER article

Replace solenoid Replace starter

Starter Engages Engine Only Momentarily

Engine timing too far advanced

Overrunning clutch not engaging properly

See Ignition Timing in TUNE-UP article

Replace overrunning clutch. See STARTER article

Broken starter clutch

Broken teeth on engine flywheel

Weak drive assembly thrust spring

Weak hold-in coil

See STARTER article

Replace flywheel and check starter pinion gear for damage

See STARTER article

See Bench Tests in STARTER article

Starter Drive Will Not Engage

Defective point assembly

Poor point assembly ground

See Testing in STARTER article

See Testing in STARTER article

Starter Relay Does Not Close

Defective pull-in coil

Dead battery Faulty wiring

Neutral safety switch faulty

Replace starter solenoid

Charge or replace battery as necessary

Check all wiring and connections leading to relay

Replace neutral safety switch

Starter relay faulty

Replace starter relay

Starter Drive Will Not Disengage

Starter motor loose on mountings

Worn drive end bushing

Damaged engine flywheel teeth

Drive yolk return spring broken or missing

Faulty ignition switch

Insufficient clearance between winding leads to solenoid terminal and main contact in solenoid

Starter clutch not disengaging

Ignition starter switch contacts sticking

Tighten starter attach bolts

See STARTER article

Replace flywheel and starter pinion gear for damage

Replace return spring

Replace ignition switch

Replace starter solenoid

Replace starter clutch

Replace ignition switch

Starter Relay Operates but Solenoid Does Not

Faulty solenoid switch, switch connections or

Broken lead or loose soldered connections

Check all wiring between relay and solenoid or replace relay or solenoid as necessary

Repair wire or wire connections as necessary

Solenoid Plunger Vibrates When Switch is Engaged

Weak battery

Solenoid contacts corroded

Faulty wiring

Broken connections inside switch cover

Open hold-in wire

Charge or replace battery as necessary

Clean contacts or replace solenoid

Check all wiring leading to solenoid

Repair connections or replace solenoid

Replace solenoid

Low Current Draw

Worn brushes or weak

Replace brushes or brush springs as necessary

High Pitched Whine During Cranking Before Engine Fires but Engine Fires and Cranks Normally

Distance too great between starter pinion and flywheel

Align starter or check that correct starter and flywheel are being used

High Pitched Whine After Engine

Distance too small between starter pinion and flywheel

Fires With Key released. Engine Fires and Cranks Normally

Flywheel runout contributes to the intermittent nature

AIR CONDITIONING & HEAT

AIR CONDITIONING TROUBLE SHOOTING

WARNING: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC AIR CONDITIONING TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

Compressor Not Working

Compressor clutch circuit open. Compressor clutch coil inoperative. Poor clutch ground connection. Fan belts loose.

Thermostatic switch inoperative. Thermostatic switch not adjusted. Ambient temperature switch open. Superheat fuse blown.

Excessive Noise or Vibration

Missing or loose mounting bolts. Bad idler pulley bearings. Fan belts not tightened correctly. Compressor clutch contacting body. Excessive system pressure. Compressor oil level low. Damaged clutch bearings. Damaged reed valves. Damaged compressor.

Insufficient or No Cooling; Compressor Working

Expansion valve inoperative.

Heater control valve stuck open.

Low system pressure.

Blocked condenser fins.

Blocked evaporator fins.

Vacuum system leak.

Vacuum motors inoperative.

Control cables improperly adjusted.

Restricted air inlet.

Mode doors binding.

Blower motor inoperative.

Temperature above system capacity.

HEATER SYSTEM TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to

problem symptoms. For model-specific Trouble Shooting, refer to DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC HEATER SYSTEM TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

Insufficient, Erratic, or No Heat

Low Coolant Level

Incorrect thermostat.

Restricted coolant flow through

heater core.

Heater hoses plugged.

Misadjusted control cable.

Sticking heater control valve.

Vacuum hose leaking.

Vacuum hose blocked.

Vacuum motors inoperative.

Blocked air inlet.

Inoperative heater blower motor.

Oil residue on heater core fins.

Dirt on heater core fins.

Too Much Heat

Improperly adjusted cables. Sticking heater control valve. No vacuum to heater control valve. Temperature door stuck open.

Air Flow Changes During Acceleration

Vacuum system leak.

Bad check valve or reservoir.

Air From Defroster At All Times

Vacuum system leak.

Improperly adjusted control cables.

Inoperative vacuum motor.

Blower Does Not Operate Correctly

Blown fuse.

Blower motor windings open.

Resistors burned out.

Motor ground connection loose.

Wiring harness connections loose.

Blower motor switch inoperative.

Blower relay inoperative.

Fan binding or foreign object

in housing.

Fan blades broken or bent.

BRAKES

BRAKE SYSTEM TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BRAKE SYSTEM TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Brakes Pull Left

or Right Incorrect tire pressure

Front end out of alignment Mismatched tires

Restricted brake lines or hoses

Loose or malfunctioning caliper

Bent shoe or oily linings Malfunctioning rear brakes Loose suspension parts

Inflate tires to proper pressure

See WHEEL ALIGNMENT Check tires sizes

Check hose routing

See DISC BRAKES or BRAKE SYSTEM

See DRUM BRAKES or BRAKE SYSTEM

See DRUM, DISC BRAKES or BRAKE SYSTEM

See SUSPENSION

Noises Without Brakes Applied

Front linings worn out

Dust or oil on drums or rotors

Replace linings

See DRUM, DISC BRAKES or BRAKE SYSTEM

Noises With Brakes Applied

Insulator on outboard shoe damaged

See DISC BRAKES or BRAKE SYSTEM

Incorrect pads or linings Replace pads or linings Brake Rough, Chatters

or Pulsates Excessive lateral runout

Parallelism not to specifications

Wheel bearings not adjusted Rear drums out-of-round

Disc pad reversed, steel against rotor

Check rotor runout

Reface or replace rotor

See SUSPENSION

Reface or replace drums

Remove and reinstall pad

Excessive Pedal

Effort Malfunctioning power unit

Partial system failure Worn disc pad or lining Caliper piston stuck or

See POWER BRAKES or BRAKE SYSTEM

Check fluid and pipes Replace pad or lining

sluggish

See DISC BRAKES or BRAKE SYSTEM

Master cylinder piston stuck

See MASTER CYLINDERS or BRAKE SYSTEM

Brake fade due to incorrect pads for linings

Linings or pads glazed Worn drums

Replace pads or linings Replace pads or linings Reface or replace drums

Excessive Pedal Travel

Partial brake system failure Check fluid and pipes

Insufficient fluid in master cylinder

Air trapped in system

Rear brakes not adjusted

Bent shoe or lining

Plugged master cylinder cap

Improper brake fluid

See MASTER CYLINDERS or BRAKE SYSTEM

See BRAKE BLEEDING or BRAKE SYSTEM

See Adjustments in DRUM BRAKES or BRAKE SYSTEM

See DRUM BRAKES or BRAKE SYSTEM

See MASTER CYLINDERS or BRAKE SYSTEM

Replace brake fluid

Pedal Travel Decreasing

Compensating port plugged

Swollen cup in master cylinder

Master cylinder piston not returning

See MASTER CYLINDERS or BRAKE SYSTEM

See MASTER CYLINDERS or BRAKE SYSTEM

See MASTER CYLINDERS or BRAKE SYSTEM

Weak shoe retracting springs See DRUM BRAKES

BRAKE SYSTEM

Wheel cylinder piston sticking

See DRUM BRAKES or BRAKE SYSTEM

Dragging Brakes

Master cylinder pistons not returning

See MASTER CYLINDERS BRAKE SYSTEM

Restricted brake lines

or hoses

Incorrect parking brake

adjustment

Check line routing

See DRUM BRAKES BRAKE SYSTEM

Parking Brake cables frozen See DRUM BRAKES

BRAKE SYSTEM

Incorrect installation of inboard disc pad

Power booster output rod too long

Brake pedal not returning freely

Remove and replace correctly

See POWER BRAKE UNITS BRAKE SYSTEM

See DISC, DRUM BRAKES BRAKE SYSTEM

Brakes Grab or Uneven Braking Action

Malfunction of combination valve

Malfunction of power brake unit

Binding brake pedal

See CONTROL VALVE or BRAKE SYSTEM

See POWER BRAKE UNITS or BRAKE SYSTEM

See DISC, DRUM BRAKES or BRAKE SYSTEM

Pulsation or Roughness

Uneven pad wear caused by caliper

Uneven rotor wear

Drums out-of-round

See DISC BRAKES or BRAKE SYSTEM

See DISC BRAKES or BRAKE SYSTEM

Reface or replace drums

ENGINE MECHANICAL

COOLING SYSTEM TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

COOLING SYSTEM TROUBLE SHOOTING

CONDITION

POSSIBLE CAUSE

CORRECTION

Overheating

Coolant Leak

A/C Condenser Fins Clogged Radiator Fins Clogged Thermostat Stuck Closed

Clogged Cooling System Passages

Fill/Pressure Test

System

Remove/Clean Condenser

Remove/Clean Radiator Replace Thermostat

Clean/Flush Cooling System

Water Pump Malfunction Fan Clutch Malfunction Retarded Ignition Timing Cooling Fan Malfunction

Cooling Fan Motor Malfunction

Cooling Fan Relay Malfunction

Faulty Radiator Cap Broken/Slipping Fan Belt Restricted Exhaust

Replace Water Pump Replace Fan Clutch Reset Ignition Timing

Test Cooling Fan/ Circuit

Test Fan Motor

Test Fan Relay Replace Radiator Cap Replace Fan Belt Repair Exhaust System

Corrosion

Impurities In Coolant

Clean/Flush System

Coolant Leakage

Damaged hose Leaky Water Pump Damaged Radiator Seam Leaky Thermostat Cover

Cylinder Head Problem Leaky Freeze Plugs

Replace Hose Replace Water Pump Replace/Repair Radiator

Replace Thermostat Cover

Check Head/Head Gasket Replace Freeze Plugs

Recovery System Inoperative

Loose and/or Defective Radiator Cap

Overflow Tube Clogged and/or Leaking

Recovery Bottle Vent Restricted

Replace Radiator Cap Repair Tube Clean Vent

No Heater Core Flow

Collapsed Heater Hose

Plugged Heater Core

Faulty Heater Valve

Replace Heater Hose

Clean/Replace Heater Core

Replace Heater Valve

GASOLINE ENGINE - MECHANICAL TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available

in the section(s) you are accessing. BASIC GASOLINE ENGINE - MECHANICAL TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Engine Lopes At Idle

Intake manifold-to-head

leaks

Blown head gasket

Worn timing gears, chain

or sprocket

Worn camshaft lobes

Overheated engine

Blocked crankcase vent

valve

Leaking EGR valve

Faulty fuel pump

Replace manifold

gasket, See ENGINES

Replace head gasket,

See ENGINES

Replace gears, chain or

sprocket

Replace camshaft, See

ENGINES

Check cooling system,

See COOLING

Remove restriction

Repair leak and/or replace valve Replace fuel pump

Engine Has Low Power

Leaking fuel pump

Excessive piston-to-bore

clearance

Sticking valves or weak

valve springs

Incorrect valve timing

Worn camshaft lobes Blown head gasket Clutch slipping

Engine overheating

Auto. Trans. pressure regulator valve faulty

Auto. Trans. fluid level too low

Improper vacuum diverter valve operation

Vacuum leaks Leaking piston rings

Repair leak and/or

replace fuel pump

Install larger pistons,

See ENGINES

Check valve train

components, See ENGINES

Reset valve timing, See

ENGINES

Replace camshaft, See

ENGINES

Replace head gasket.

See ENGINES.

Adjust pedal and/or

replace components, See

ENGINES

Check cooling system,

See COOLING

Replace pressure

regulator valve

Add fluid as necessary

Replace vacuum diverter

valve

Inspect vacuum system

and repair as required

Replace piston rings,

See ENGINES

Faulty High Speed Operation

Low fuel pump volume Leaking valves or worn Incorrect valve timing

Intake manifold restricted Worn distributor shaft

Replace fuel pump

Replace valves and/or

springs, See ENGINES

Reset valve timing,See

ENGINES

Remove restriction

Replace distributor

Faulty Acceleration

Improper fuel pump stroke

Remove pump and reset pump stroke

Incorrect ignition timing Leaking valves

Worn fuel pump diaphragm or piston

Reset ignition timing,

See TUNE-UP

Replace valves, See

ENGINES

Replace diaphragm or

piston

Intake Backfire Improper ignition timing

Faulty accelerator pump

discharge

Improper choke operation

Defective EGR valve Fuel mixture too lean

Choke valve initial clearance too large

Reset ignition timing,

See TUNE-UP

Replace accelerator

pump

Check choke and adjust

as required

Replace EGR valve

Reset air/fuel mixture,

See TUNE-UP

Reset choke valve

initial clearance

Exhaust Backfire Vacuum leak

Faulty vacuum diverter

valve

Faulty choke operation

Exhaust system leak

Inspect and repair

vacuum system

Replace vacuum diverter

valve

Check choke and adjust

as required

repair exhaust system

leak

Engine Detonation

Ignition timing too far

advanced

Faulty ignition system

Spark plugs loose or

faulty

Fuel delivery system

clogged

EGR valve inoperative

PCV system inoperative

Vacuum leaks

Excessive combustion chamber deposits

Leaking, sticking or broken valves

Reset ignition timing,

See TUNE-UP

Check ignition timing,

See TUNE-UP

Retighten or replace

plugs

Inspect lines, pump and

filter for clog

Replace EGR valve

Inspect and/or replace

hoses or valve

Check vacuum system and

repair leaks

Remove built-up

deposits

Inspect and/or replace

valves

External Oil Leakage

Fuel pump improperly seated or worn gasket

Oil pan gasket broken or

pan bent

Timing chain cover gasket

broken

Rear main oil seal worn

Oil pan drain plug not seated properly Camshaft bearing drain hole blocked Oil pressure sending switch leaking

Remove pump, replace

gasket and seat

properly

Straighten pan and

replace gasket

Replace timing chain

cover gasket

Replace rear main oil

seal

Remove and reinstall

drain plug

Remove restriction

Remove and reinstall sending switch

Excessive Oil Consumption

Worn valve stems or guides

Valve "O" ring seals

damaged

Plugged oil drain back holes

Improper PCV valve

operation

Engine oil level too high

Engine oil too thin

Valve stem oil deflectors

damaged

Incorrect piston rings

Piston ring gaps not

staggered

Insufficient piston ring

tension

Piston ring grooves or oil

return slots clogged

Piston rings sticking in

grooves

Piston ring grooves

excessively worn

Compression rings installed

upside down

Worn or scored cylinder

walls

Mismatched oil ring

expander and rail

Intake gasket dowels too

long

Excessive main or connecting

rod bearing clearance

Replace stems or guides, See ENGINES Replace "O" ring seals, See ENGINES Remove restrictions Replace PCV valve

Remove excess oil Replace thicker oil Replace oil deflectors

Replace piston rings,

See ENGINES

Reinstall piston rings,

See ENGINES

Replace rings, See

ENGINES

Replace piston rings,

See ENGINES

Replace piston rings,

See ENGINES

Replace piston and

rings, See ENGINES

Replace compression

rings correctly, See

ENGINES

Rebore cylinders or

replace block

Replace oil ring

expander and rail, See

ENGINES

Replace intake gasket

dowels

Replace main or

connecting rod

bearings, See ENGINES

No Oil Pressure

Low oil level

Oil pressure sender or

gauge broken

Oil pump malfunction

Oil pressure relief valve

sticking

Oil pump passages blocked

Oil pickup screen or tube

blocked

Loose oil inlet tube

Loose camshaft bearings

Internal leakage at oil passages

Add oil to proper level Replace sender or gauge

Remove and overhaul oil

pump, See ENGINES

Remove and reinstall

valve

Overhaul oil pump, See

ENGINES

remove restriction

Tighten oil inlet tube Replace camshaft bearings, See ENGINES Replace block or cylinder head

Low Oil Pressure

Low engine oil level Engine oil too thin

Excessive oil pump

clearance

Oil pickup tube or screen

blocked

Main, rod or cam bearing

clearance excessive

Add oil to proper level Remove and replace with thicker oil Reduce oil pump clearance, See ENGINES Remove restrictions

Replace bearing to reduce clearance, See

ENGINES

High Oil Pressure

Improper grade of oil Oil pressure relief valve stuck closed Oil pressure sender or gauge faulty

Replace with proper oil Eliminate binding

Replace sender or gauge

Noisy Main Bearings

Inadequate oil supply

Excessive main bearing

clearance

Excessive crankshaft end

play

Loose flywheel or torque

converter

Loose or damaged vibration

damper

Crankshaft journals

out-of-round

Excessive belt tension

Check oil delivery to

main bearings

Replace main bearings,

See ENGINES

Replace crankshaft, See

ENGINES

Tighten attaching bolts

Tighten or replace

vibration damper

Re-grind crankshaft

journals

Loosen belt tension

Noisy Connecting Excessive bearing clearance Replace bearing, See

Rods

or missing bearing

Crankshaft rod journal

out-of-round

Misaligned connecting rod

or cap

Incorrectly tightened rod

bolts

ENGINES

Re-grind crankshaft

journal

Remove rod or cap and

realign

Remove and re-tighten

rod bolts

Noisy Pistons and Rings

Excessive piston-to-bore

clearance

Bore tapered or out-of-round

Piston ring broken

Piston pin loose or seized

Connecting rods misaligned Ring side clearance too loose or tight Carbon build-up on piston

Install larger pistons,

See ENGINES

Rebore block

Replace piston rings,

See ENGINES

Replace piston pin, See

ENGINES

Realign connecting rods

Replace with larger or

smaller rings

Remove carbon

Noisy Valve Train

Worn or bent push rods

Worn rocker arms or bridged

pivots

Dirt or chips in valve

lifters

Excessive valve lifter

leak-down

Valve lifter face worn

Broken or cocked valve

springs

Too much valve stem-to-guide

clearance

Valve bent

Loose rocker arms

Excessive valve seat run-out

Replace push rods, See

ENGINES

Replace push rods, See

ENGINES

Remove lifters and

remove dirt/chips

Replace valve lifters,

See ENGINES

Replace valve lifters,

See ENGINES

replace or reposition

springs

Replace valve guides,

See ENGINES

Replace valve, See

ENGINES

Retighten rocker arms,

See ENGINES

Reface valve seats, See

ENGINES

Noisy Valves

Missing valve lock

Excessively worn camshaft

lobes

Plugged valve lifter oil

holes

Faulty valve lifter check

ball

Rocker arm nut installed

upside down

Valve lifter incorrect for

engine

Faulty push rod seat or

lifter plunger

Improper valve lash

Worn or dirty valve lifters

Worn valve guides

Excessive valve seat or

face run-out

Worn camshaft lobes

Loose rocker arm studs Bent push rods Broken valve springs

Install new valve lock

Replace camshaft, See

ENGINES

Eliminate restriction

or replace lifter

Replace lifter check

ball, See ENGINES

Remove and reinstall

correctly

Remove and replace

valve lifters

Replace plunger or push

rod

Re-adjust valve lash,

See ENGINES

Clean and/or replace

lifters

Replace valve guides,

See ENGINES

Reface seats or valve

face

Replace camshaft, See

ENGINES

Re-tighten rocker arm

studs, See ENGINES

Replace push rods, See

ENGINES

Replace valve springs,

See ENGINES

Burned,Sticking or Broken Valves

Broken Pistons/Rings

Weak valve springs or

warped valves

Improper lifter clearance

Worn guides or improper guide clearance Out-of-round valve seats or improper seat width Gum deposits on valve stems, seats or guides Improper spark timing

Undersize pistons Wrong piston rings

Out-of-round cylinder bore

Improper connecting rod

alignment

Excessively worn ring

grooves

Improperly assembled

piston pins

Insufficient ring gap

clearance

Engine overheating

Incorrect ignition timing

Replace valves and/or springs, See ENGINES Re-adjust clearance or replace lifters Replace valve guides, See ENGINES Re-grind valve seats

Remove deposits Re-adjust spark timing

Replace with larger pistons, See ENGINES Replace with correct rings, See ENGINES Re-bore cylinder bore Remove and realign connecting rods Replace pistons, See ENGINES

Re-assemble pin-to -piston, See ENGINES Install new rings, See ENGINES

Check cooling system Re-adjust ignition timing, See TUNE-UP

Excessive Exhaust Noise

Leaks at manifold to head, or to pipe Exhaust manifold

Replace manifold or pipe gasket Replace exhaust

cracked or broken

manifold, See ENGINES

ENGINE PERFORMANCE

CARBURETOR TROUBLE SHOOTING:

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC COLD START SYMPTOMS TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Engine WonÆt Start

Choke not closing

Choke linkage bent

Check choke operation, see FUEL SYSTEMS

Check linkage, see FUEL SYSTEM

Engine Starts, Then Dies

Choke vacuum kick setting too wide

Fast idle RPM too low

Fast idle cam index incorrect

Check setting and adjust see, FUEL SYSTEMS

Reset RPM to specif┬Łication, see TUNE-UP

Reset fast idle cam index, see FUEL SYSTEMS

Vacuum leak

Low fuel pump outlet

Inspect vacuum system for leaks

Repair or replace pump, see FUEL SYSTEMS

Low carburetor fuel level

Check float setting see FUEL SYSTEM

Engine Quits Under Load

Choke vacuum kick setting incorrect

Fast idle cam index incorrect

Incorrect hot fast idle speed RPM

Reset vacuum kick setting,see FUEL SYSTEMS

Reset fast idle cam index, see FUEL SYSTEM

Reset fast idle RPM, see TUNE-UP

Engine Starts, Runs Up,Then Idles, Slowly With Black Smoke

Choke vacuum kick set too narrow

Fast idle cam index

Reset vacuum kick, see FUEL SYSTEMS

Reset fast idle cam

incorrect

Hot fast idle RPM too low

index, see FUEL SYSTEMS

Reset fast idle RPM, see TUNE-UP

BASIC HOT START SYMPTOMS TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Engine WonÆt Start

Engine flooded

Allow fuel to evaporate

BASIC COLD ENGINE DRIVEABILITY SYMPTOMS TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Engine Stalls in Choke vacuum kick setting

Gear incorrect

Reset choke vacuum kick, see FUEL SYSTEMS

Fast idle RPM incorrect

Reset fast idle RPM, see TUNE-UP

Fast idle cam index incorrect

Reset fast idle cam see FUEL SYSTEMS

Acceleration Sag or Stall

Defective choke control switch

Replace choke control switch

Choke vacuum kick setting incorrect

Reset choke vacuum kick see, FUEL SYSTEMS

Float level incorrect (too low)

Accelerator pump defective

Adjust float level, FUEL SYSTEMS

Repair or replace pump see FUEL SYSTEMS

Secondary throttles not closed

Inspect lockout adjustment,see FUEL SYSTEMS

Sag or Stall After Warmup

Defective choke control switch

Defective accelerator pump

Replace choke control switch, see FUEL SYSTEMS

Replace pump, see FUEL SYSTEMS

Float level incorrect (too low)

Adjust float level, see FUEL SYSTEMS

Backfiring & Black Smoke

Plugged heat crossover system

Remove restriction

BASIC WARM ENGINE DRIVEABILITY SYMPTOMS TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Hesitation With Small Amount of Gas Pedal Movement

Vacuum leak

Accelerator pump weak or inoperable

Float level setting too low

Metering rods sticking or binding

Carburetor idle or transfer system plugged

Frozen or binding heated air inlet

Inspect vacuum lines

Replace pump, see FUEL SYSTEMS

Reset float level, see,FUEL SYSTEMS

Inspect and/or replace rods, see FUEL SYSTEMS

Inspect system and remove restriction

Inspect heated air door for binding

Hesitation With Heavy Gas Pedal Movement

Defective accelerator pump

Replace pump, see FUEL SYSTEMS

Metering rod carrier sticking or binding

Large vacuum leak

Remove restriction

Inspect vacuum system and repair leak

Float level setting too low

Defective fuel pump, lines or filter

Air door setting incorrect

Reset float level, see FUEL SYSTEMS

Inspect pump, lines and filter

Adjust air door setting, see FUEL

DIESEL ENGINE TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

NOTE: Diesel engines mechanical diagnosis is the same as gasoline engines for items such as noisy valves, bearings, pistons, etc. The following trouble shooting covers only items pertaining to diesel engines.

BASIC DIESEL ENGINE TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Engine WonÆt Crank

Bad battery connections or dead batteries

Check connections and/or replace

Bad starter connections or bad starter

batteries

Check connections

and/or replace

batteries

Engine Cranks Slowly, WonÆt Start

Bad battery connections or dead batteries

Engine oil too heavy

Check connections and/or replace batteries Replace engine oil

Engine Cranks Normally, But Will Not Start

Glow plugs not functioning

Glow plug control not

functioning

Fuel not injected into

cylinders

No fuel to injection pump

Fuel filter blocked Fuel tank filter blocked

Fuel pump not operating Fuel return system blocked No voltage to fuel solenoid

Incorrect or contaminated

fuel

Incorrect injection pump

timing

Low compression

Injection pump malfunction

Check glow plug system,

see FUEL SYSTEMS

Check controller, see

FUEL SYSTEMS

Check fuel injectors,

see FUEL SYSTEMS

Check fuel delivery

system

Replace fuel filter

Replace fuel tank

filter

Check pump operation

and/or replace pump

Inspect system and

remove restriction

Check solenoid and

connections

Replace fuel

Re-adjust pump timing, see FUEL SYSTEMS Check valves, pistons, rings, see ENGINES Inspect and/or replace injection pump

Engine Starts, Incorrect slow idle WonÆt Idle adjustment

Fast idle solenoid

malfunctioning

Fuel return system blocked

Glow plugs go off too soon

Injection pump timing

incorrect

No fuel to injection pump

Incorrect or contaminated

fuel

Low compression

Injection pump malfunction

Fuel solenoid closes in RUN position

Reset idle adjustment,

see TUNE-UP

Check solenoid and

connections

Check system and remove

restrictions

See glow plug diagnosis

in FUEL SYSTEMS

Reset pump timing, see

FUEL SYSTEMS

Check fuel delivery

system

Replace fuel

Check valves, piston, rings, see ENGINES Replace injection pump, see FUEL SYSTEMS Check solenoid and connections

Engines Starts/ Incorrect slow idle

Idles Rough W/out adjustment

Smoke or Noise Injection line fuel leaks

Fuel return system blocked

Reset slow idle, see

TUNE-UP

Check lines and

connections

Check lines and

connections

Air in fuel system

Incorrect or contaminated

fuel

Injector nozzle malfunction

Bleed air from system Replace fuel

Check nozzles, see FUEL SYSTEMS

Engines Starts and Idles Rough W/out Smoke or Noise, But Clears After Warm-Up

Injection pump timing

incorrect

Engine not fully broken in

Air in system

Injector nozzle malfunction

Reset pump timing, see

FUEL SYSTEMS

Put more miles on

engine

Bleed air from system

Check nozzles, see

FUEL SYSTEMS

Engine Idles Correctly, Misfires Above Idle

Blocked fuel filter

Injection pump timing

incorrect

Incorrect or contaminated

fuel

Replace fuel filter Reset pump timing, see FUEL SYSTEMS Replace fuel

Engine WonÆt Return To Idle

Fast idle adjustment

incorrect

Internal injection pump

malfunction

External linkage binding

Reset fast idle, see

TUNE-UP

Replace injection pump,

see FUEL SYSTEMS

Check linkage and

remove binding

Fuel Leaks On Ground

Loose or broken fuel line

Internal injection pump seal leak

Check lines and

connections

Replace injection pump,

see FUEL SYSTEMS

Cylinder Knocking Noise

Injector nozzles sticking

open

Very low nozzle opening

pressure

see

Test injectors,

FUEL SYSTEMS

Test injectors and/or

replace

Loss of Engine Power

Restricted air intake EGR valve malfunction Blocked or damaged exhaust system

Blocked fuel tank filter Restricted fuel filter

Block vent in gas cap

Tank-to-injection pump fuel

supply blocked

Blocked fuel return system

Incorrect or contaminated

fuel

Blocked injector nozzles

Low compression

Remove restriction Replace EGR valve Remove restriction and/or replace components Replace filter Remove restriction and/or replace filter Remove restriction and/or replace cap Check fuel lines and connections Remove restriction Replace fuel

Check nozzle for

blockage, see FUEL

SYSTEMS

Check valves, rings,

pistons, see ENGINES

Loud Engine Basic timing incorrect Noise With Black

Smoke

EGR valve malfunction Internal injection pump malfunction

Reset timing, see FUEL SYSTEMS Replace EGR valve Replace injection pump, see FUEL SYSTEMS

Incorrect injector pump housing pressure

Check pressure, see FUEL SYSTEMS

Engine Overheating

Cooling system leaks Belt slipping or damaged Thermostat stuck closed

Head gasket leaking

Check cooling system and repair leaks Check tension and/or replace belt Remove and replace thermostat, see ENGINE COOLING Replace head gasket

Oil Light on at Idle

Low oil pump pressure

Oil cooler or line restricted

Check oil pump operation, see ENGINES Remove restriction and/or replace cooler

Engine WonÆt Shut Off

Injector pump fuel solenoid does not return fuel valve to OFF position

Remove and check solenoid and replace if needed

Excessive Noise

Oil Leakage

VACUUM PUMP DIAGNOSIS

Loose pump-to-drive

assembly screws

Loose tube on pump assembly

Valves not functioning

properly

Loose end plug Bad seal crimp

Tighten screws

Tighten tube Replace valves

Tighten end plug Remove and re-crimp seal

FUEL INJECTION TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC FUEL INJECTION TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Engine WonÆt Start (Cranks Normally)

Cold start valve inoperative

Poor connection;vacuum or wiring

Contaminated fuel

Defective fuel pump relay or circuit

Battery too low

Test valve and circuit

Check vacuum and

electrical

connections

Test fuel for water or alcohol

Test relay and wiring

Charge and test battery

Low fuel pressure

No distributor reference pulses

Open coolant temperature sensor circuit

Shorted W.O.T. switch in T.P.S.

Defective ECM

Fuel tank residual pressure valve leaks

Test pressure regul┬Łator and fuel pump, check for restricted lines and filters

Repair ignition system as necessary

Test sensor and wiring

Disconnect W.O.T. switch, engine should start

Replace ECM

Test for fuel pressure drop after shut down

Hard Starting

Disconnected hot air tube to air cleaner

Defective Idle Air Control (IAC) valve

Shorted, open or misadjusted T.P.S.

EGR valve open

Poor Oxygen sensor signal

Incorrect mixture from PCV system

Reconnect tube and test control valve

Test valve operation and circuit

Test and adjust or replace T.P.S.

Test EGR valve and control circuit

Test for shorted or circuit

Test PCV for flow, check sealing of oil filter cap

Poor High Speed Operation

Low fuel pump volume

Poor MAP sensor signal

Poor Oxygen sensor signal

Open coolant temperature sensor circuit

Faulty ignition operation

Faulty pump or restricted fuel lines or filters

Test MAP sensor, vacuum hose and wiring

Test for shorted or open sensor or circuit

Test sensor and wiring

Check wires for cracks or poor con┬Łnections, test secondary voltage with oscilloscope

Contaminated fuel

Test fuel for water

or alcohol

Intermittent ECM ground

Restricted air cleaner Restricted exhaust system

Poor MAF sensor signal Poor VSS signal

Test ECM ground connection for resistance

Replace air cleaner

Test for exhaust manifold back pressure

Check leakage between sensor and manifold

If tester for ALCL hook-up is available check that VSS reading matches speedometer

Ping or Knock on Acceleration

Poor Knock sensor signal

Poor Baro sensor signal

Improper ignition timing

Check for engine overheating problems

Test for shorted or open sensor or circuit

Test for shorted or open sensor or circuit

See VEHICLE EMISSION CONTROL LABEL (where applicable)

Low coolant, loose belts or electric cooling fan inoperative

NOTE: For additional electronic fuel injection trouble shooting information, see the appropriate article in the ENGINE PERFORMANCE section (not all vehicles have Computer Engine Control articles). Information is provided there for diagnosing fuel system problems on vehicles with electronic fuel injection.

IGNITION SYSTEM TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

Ignition Secondary Trouble Shooting Chart

STARTER TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC STARTER TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Starter Fails to Operate

Dead battery or bad connections between starter and battery

Check battery charge and all wires and connections to starter

Ignition switch faulty or misadjusted

Open circuit between starter switch ignition terminal on starter relay

Starter relay or starter defective

Open solenoid pull-in wire

Adjust or replace ignition switch

Check and repair wires and connections as necessary

See Testing in STARTER article

See Testing in STARTER article

Starter Does Not Operate and Headlights Dim

Weak battery or dead cell

Loose or corroded battery connections

Internal ground in starter windings

Grounded starter fields

Armature rubbing on pole shoes

Charge or replace battery as necessary

Check that battery connections are clean and tight

See Testing in STARTER article

See Testing in STARTERS See STARTER article

Starter Turns but Engine Does Not Rotate

Starter clutch slipping

Broken clutch housing

Pinion shaft rusted or dry

Engine basic timing incorrect

Broken teeth on engine flywheel

See STARTER article

See STARTER article See STARTER article

See Ignition Timing in TUNE-UP article

Replace flywheel and check for starter pinion gear damage

Starter Will Not Crank Engine

Faulty overrunning clutch

Broken clutch housing Broken flywheel teeth

Armature shaft sheared or reduction gear teeth stripped

Weak battery

Faulty solenoid

See STARTER article

See STARTER article

Replace flywheel and check for starter pinion gear damage

See STARTER article

Charge or replace battery as necessary

See On-Vehicle Tests in STARTER article

Poor grounds

Check all ground

connections for tight and clean connections

Ignition switch faulty or misadjusted

Adjust or replace ignition switch as necessary

Starter Cranks Engine Slowly

Battery weak or defective

Engine overheated

Charge or replace battery as necessary

See ENGINE COOLING SYSTEM article

Engine oil too heavy

Check that proper viscosity oil is used

Poor battery-to-starter connections

Current draw too low or too high

Bent armature, loose pole shoes screws or worn bearings

Burned solenoid contacts Faulty starter

Check that all

between

battery and starter are

clean and tight

See Bench Tests in STARTER article

See STARTER article

Replace solenoid Replace starter

Starter Engages Engine Only Momentarily

Engine timing too far advanced

Overrunning clutch not engaging properly

See Ignition Timing in TUNE-UP article

Replace overrunning clutch. See STARTER article

Broken starter clutch

Broken teeth on engine flywheel

Weak drive assembly thrust spring

Weak hold-in coil

See STARTER article

Replace flywheel and check starter pinion gear for damage

See STARTER article

See Bench Tests in STARTER article

Starter Drive Will Not Engage

Defective point assembly

Poor point assembly ground

Defective pull-in coil

See Testing in STARTER article

See Testing in STARTER article

Replace starter solenoid

Starter Relay

Dead battery

Charge or replace

Does Not Close

battery as necessary

Faulty wiring

Neutral safety switch faulty

Starter relay faulty

Check all wiring and connections leading to relay

Replace neutral safety switch

Replace starter relay

Starter Drive Will Not Disengage

Starter motor loose on mountings

Worn drive end bushing

Damaged engine flywheel teeth

Drive yolk return spring broken or missing

Faulty ignition switch

Insufficient clearance between winding leads to solenoid terminal and main contact in solenoid

Tighten starter attach bolts

See STARTER article

Replace flywheel and starter pinion gear for damage

Replace return spring

Replace ignition switch

Replace starter solenoid

Starter clutch not disengaging

Ignition starter switch contacts sticking

Replace starter clutch

Replace ignition switch

Starter Relay Operates but Solenoid Does Not

Faulty solenoid switch, switch connections or

Broken lead or loose soldered connections

Check all wiring between relay and solenoid or replace relay or solenoid as necessary

Repair wire or wire connections as necessary

Solenoid Plunger Vibrates When Switch is Engaged

Weak battery

Solenoid contacts corroded

Faulty wiring

Broken connections inside switch cover

Open hold-in wire

Charge or replace battery as necessary

Clean contacts or replace solenoid

Check all wiring leading to solenoid

Repair connections or replace solenoid

Replace solenoid

Low Current Draw Worn brushes or weak

Replace brushes or brush springs as necessary

High Pitched Whine Distance too great

During Cranking Before Engine Fires but Engine Fires and Cranks Normally

between starter pinion and flywheel

Align starter or check that correct starter and flywheel are being used

High Pitched Distance too small between Whine After Engine starter pinion and flywheel Fires With Key Flywheel runout contributes released. Engine to the intermittent nature Fires and Cranks Normally

TUNE-UP TROUBLE SHOOTING - GAS ENGINE VEHICLES

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC SPARK PLUG TROUBLE SHOOTING CHARTS

CONDITION

POSSIBLE CAUSE

CORRECTION

Normal Spark Plug Condition

Light Tan or Gray deposits No Action

Electrode not burned or No Action fouled

Gap tolerance not changed

No Action

Cold Fouling or Carbon Deposits

Overrich air/fuel mixture

Faulty choke

Clogged air filter

Incorrect idle speed or dirty carburetor

Faulty ignition wires

Prolonged operation at idle

Sticking valves or worn valve guide seals

Adjust air/fuel mixture, see ENGINE PERFORMANCE section

Replace choke assembly, see ENGINE PERFORMANCE section

Clean and/or replace air filter

Reset idle speed and/ or clean carburetor

Replace ignition wiring

Shut engine off during long idle

Check valve train

Wet Fouling

or Oil Deposits

Worn rings and pistons

Install new rings and pistons

Excessive cylinder wear

Excessive valve guide clearance

Rebore or replace block

Worn or loose bearing

Gap Bridged

Deposits in combustion chamber becoming fused to electrode

Clean combustion chamber of deposits

Blistered Electrode

Engine overheating Wrong type of fuel

Loose spark plugs

Over-advanced ignition timing

Check cooling system

Replace with correct fuel

Retighten spark plugs

Reset ignition timing see ENGINE PERFORMANCE

Pre-Ignition or Incorrect type of fuel Melted Electrodes

Incorrect ignition timing

Replace with correct fuel

Reset ignition timing see ENGINE PERFORMANCE

Burned valves Engine Overheating

Wrong type of spark plug, too hot

Replace valves Check cooling system

Replace with correct spark plug, see ENGINE PERFORMANCE

Chipped Insulators

Severe detonation

Improper gapping procedure

Check for over-advanced timing or combustion

Re-gap spark plugs

Rust Colored Deposits

Additives in unleaded fuel

Try different fuel brand

Water In Combus┬Łtion Chamber

Blown head gasket or cracked head

Repair or replace head or head gasket

NOTE: Before diagnosing an electronic ignition system, ensure that all wiring is connected properly between distributor, wiring connector and spark plugs. Ignition problem will show up either as: Engine Will Not Start or Engine Runs Rough.

BASIC ELECTRONIC IGNITION TROUBLE SHOOTING CHARTS

CONDITION

POSSIBLE CAUSE

CORRECTION

Engine WonÆt Start

Open circuit between distributor and bulkhead connector

Repair circuit

Open circuit between bulkhead connector and

Repair circuit

ignition switch

Open circuit between ignition switch and starter solenoid

Repair circuit

Engine Runs Rough

Fuel lines leaking or clogged

Initial timing incorrect

Centrifugal advance malfunction

Defective spark plugs or wiring

Tighten fitting, remove restriction

Reset ignition timing see ENGINE PERFORMANCE

Repair distributor advance

Replace plugs or plug wiring

Component Failure Spark arc-over on cap,

rotor or coil

Defective pick-up coil Defective ignition coil Defective vacuum unit Defective control module

Replace cap, rotor or or coil

Replace pick-up coil Replace ignition coil Replace vacuum unit Replace control module

BASIC ELECTRONIC IGNITION TROUBLE SHOOTING CHARTS - USING OSCILLOSCOPE PATTERNS

CONDITION

POSSIBLE CAUSE

CORRECTION

Firing Voltage Retarded ignition timing Lines are the Same, but Abnormally High

Fuel mixture too lean

High resistance in coil wire

Corrosion in coil tower terminal

Corrosion in distributor coil terminal

Reset ignition timing, see ENGINE PERFORMANCE section

Readjust carburetor, see ENGINE PERFORMANCE

Replace coil wire

Clean and/or replace coil

Clean and/or replace distributor cap

Firing Voltage Fuel mixture too rich Lines are the Same but Abnormally Low

Breaks in coil wire causing

arcing

Cracked coil tower causing arcing

Low coil output

Low engine compression

Readjust carburetor, see ENGINE PERFORMANCE

Replace coil wire

Replace coil

Replace coil Determine cause and

repair

One or More, But Carburetor idle mixture

Not All Firing not balanced

Voltage Lines are

Higher Than Others EGR valve stuck open

High resistance in spark plug wires

Cracked or broken spark plug insulator

Intake vacuum leak Defective spark plugs

Corroded spark plug terminals

Readjust carburetor, see ENGINE PERFORMANCE

Clean and/or replace valve

Replace spark plug wires

Replace spark plugs

Repair leak Replace spark plugs Replace spark plugs

One or More, But Curb idle mixture not Not All Firing balanced Voltage Lines Are

Lower Than Others Breaks in plug wires

causing arcing

Cracked coil tower causing arcing

Low compression

Defective spark plugs Corroded spark plugs

Readjust carburetor, see ENGINE PERFORMANCE

Replace plug wires

Replace coil

Determine cause and repair

Replace spark plugs Replace spark plugs

Cylinders Not Firing

Cracked distributor cap terminals

Shorted spark plug wire

Mechanical problem in engine

Defective spark plugs Spark plugs fouled

Replace distributor cap

Determine cause and repair

Determine cause and repair

Replace spark plugs Replace spark plugs

BASIC DRIVEABILITY PROBLEMS TROUBLE SHOOTING TABLE

CONDITION

POSSIBLE CAUSE

CORRECTION

Hard Starting

Binding carburetor linkage Binding choke linkage Binding choke piston Restricted choke vacuum

Eliminate binding Eliminate binding Eliminate binding

Check vacuum lines for blockage

Worn or dirty needle valve and seat

Float sticking

Incorrect choke adjustment

Defective coil Improper spark plug gap Incorrect ignition timing

Clean carburetor, see ENGINE PERFORMANCE

Readjust or replace float see the ENGINE PERFORMANCE section

Reset choke adjustment see ENGINE PERFORMANCE

Replace coil Regap spark plugs

Reset ignition timing see ENGINE PERFORMANCE

Detonation

Over-advanced ignition timing

Defective spark plugs Fuel lines clogged EGR system malfunction

PCV system malfunction Vacuum leaks

Loose fan belts

Restricted airflow

Vacuum advance malfunction

Reset ignition timing see ENGINE PERFORMANCE

Replace spark plugs Clean fuel lines

Check and repair EGR system

Repair PCV system

Check and repair vacuum system

Tighten or replace fan belts, see ENGINE PERFORMANCE

Remove restriction

Check distributor operation

Dieseling

Binding carburetor linkage Binding throttle linkage

Binding choke linkage or fast idle cam

Defective idle solenoid Improper base idle speed Incorrect ignition timing

Incorrect idle mixture setting

Eliminate binding Eliminate blinding Eliminate binding

Replace idle solenoid see ENGINE PERFORMANCE

Reset idle speed, see see ENGINE PERFORMANCE

Reset ignition timing see ENGINE PERFORMANCE

Reset idle mixture, see ENGINE PERFORMANCE

Faulty Acceleration

Incorrect ignition timing

Reset ignition timing see ENGINE PERFORMANCE

Engine cold and choke too lean

Defective spark plugs Defective coil

Adjust choke and allow engine to warm-up

Replace spark plugs Replace coil

Faulty Low Speed Operation

Clogged idle transfer slots

Restricted idle air bleeds and passages

Clogged air cleaner Defective spark plugs Defective ignition wires

Defective distributor cap

Clean idle transfer slots, see FUEL

Disassemble and clean carburetor, see FUEL

Replace air filter Replace spark plugs

Replace ignition wire see ENGINE PERFORMANCE

Replace distributor cap

Faulty High Speed Incorrect ignition timing Operation

Defective distributor centrifugal advance

Defective distributor vacuum advance

Incorrect spark plugs or plug gap

Faulty choke operation

Clogged vacuum passages

Improper size or clogged main jet

Restricted air cleaner

Defective distributor cap, rotor or coil

Reset ignition timing see ENGINE PERFORMANCE

Replace advance mechanism

Replace advance unit

Check gap and/or replace spark plugs

Check choke and repair as required

Remove restrictions

Check jet size and clean, see FUEL

Check filter and replace as necessary

Replace cap, rotor or coil

Misfire at All Speeds

Defective spark plugs

Replace spark plugs

Defective spark plug wires

Defective distributor cap, rotor, or coil

Cracked or broken vacuum hoses

Replace spark plug wires

Replace cap, rotor, or coil

Replace vacuum hoses

Vacuum leaks

Fuel lines clogged

Repair vacuum leaks Remove restriction

Hesitation

Cracked or broken vacuum hoses

Vacuum leaks

Binding carburetor linkage

Binding throttle linkage

Binding choke linkage or fast idle cam

Improper float setting

Cracked or broken ignition wires

Replace vacuum hoses

Repair Vacuum leaks Eliminate binding Eliminate binding Eliminate binding

Readjust float setting, see FUEL

Replace ignition wires

Rough idle, Missing or Stalling

Incorrect curb idle or fast idle speed

Incorrect basic timing

Improper idle mixture adjustment

Improper feedback system operation

Incorrect spark plug gap

Moisture in ignition components

Loose or broken ignition wires

Damaged distributor cap or or rotor

Faulty ignition coil

Fuel filter clogged or worn

Damaged idle mixture screw

Improper fast idle cam adjustment

Improper EGR valve operation Faulty PCV valve air flow

Choke binding or improper choke setting

Reset idle speed, see see ENGINE PERFORMANCE

Reset ignition timing see ENGINE PERFORMANCE

Reset idle mixture, see ENGINE PERFORMANCE

Check feedback system see ENGINE PERFORMANCE

Reset spark plug gap, see ENGINE PERFORMANCE

Dry components

Replace ignition wires

Replace distributor cap or rotor

Replace ignition coil Replace fuel filter

Replace idle mixture screw, see FUEL

Reset fast idle cam adjustment, see TUNE-see ENGINE PERFORMANCE

Replace EGR valve Replace PCV valve

Reset choke or eliminate binding

Vacuum leak

Repair vacuum leak

Improper float bowl fuel level

Clogged air bleed or idle passages

Clogged or worn air cleaner filter

Faulty choke vacuum diaphragm

Exhaust manifold heat valve inoperative

Improper distributor spark advance

Leaking valves or valve components

Improper carburetor mounting

Excessive play in distributor shaft

Loose or corroded wiring connections

Reset float adjustment, see FUEL

Clean carburetor passages, see FUEL

Replace air filter

Replace diaphragm,

see ENGINE PERFORMANCE

Replace heat valve

Check distributor operation

Check and repair valvetrain

Remove and remount carburetor

Replace distributor

Repair or replace as required

Engine Surges

Improper PCV valve airflow Vacuum leaks Clogged air bleeds EGR valve malfunction

Restricted air cleaner filter

Cracked or broken vacuum hoses

Cracked or broken ignition wires

Vacuum advance malfunction

Defective or fouled spark plugs

Replace PCV valve Repair vacuum leaks Remove restriction Replace EGR valve Replace air filter

Replace vacuum hoses

Replace ignition wires

Check unit and replace as necessary

Replace spark plugs

Ping or Spark Knock

Incorrect ignition timing

Distributor centrifugal or vacuum advance malfunction

Reset ignition timing see ENGINE PERFORMANCE

Check operation and replace as necessary

Carburetor setting too lean Readjust mixture

Vacuum leak

EGR valve malfunction

setting, see ENGINE PERFORMANCE

Eliminate vacuum leak Replace EGR valve

Poor Gasoline Mileage

Cracked or broken vacuum hoses

Vacuum leaks

Defective ignition wires

Incorrect choke setting

Defective vacuum advance Defective spark plugs

Binding carburetor power piston

Dirt in carburetor jets Incorrect float adjustment Defective power valve Incorrect idle speed

Replace vacuum hoses

Repair vacuum leaks Replace wires

Readjust setting, see ENGINE PERFORMANCE

Replace vacuum advance Replace spark plugs Eliminate binding

Clean and/or replace jets

Readjust float setting, see FUEL

Replace power valve, see ENGINE PERFORMANCE

Readjust idle speed

Engine Stalls

Improper float level

Leaking needle valve and seat

Vacuum leaks

Readjust float level

Replace needle valve and seat

Eliminate vacuum leaks

VACUUM PUMP - DIESEL TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

NOTE: Diesel engines mechanical diagnosis is the same as gasoline engines for items such as noisy valves, bearings, pistons, etc. The following trouble shooting covers only items pertaining to diesel engines.

VACUUM PUMP (DIESEL) TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Excessive Noise

Loose pump-to-drive

assembly screws

Loose tube on pump assembly

Valves not functioning

properly

Tighten screws

Tighten tube Replace valves

Oil Leakage

Loose end plug Bad seal crimp

Tighten end plug Remove and re-crimp seal

MANUAL TRANSMISSION

MANUAL TRANSMISSION TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

MANUAL TRANSMISSION/TRANSAXLE TROUBLE SHOOTING

Condition

Possible Cause

Noisy In Forward Gears

.Low gear oil level, .Loose bell housing bolts, .Worn bearings or gears

Clunk On Deceleration (FWD Only)

.Loose engine mounts, .Worn inboard CV joints, .Worn differential pinion shaft, .Side gear hub counterbore in case worn oversize

Gear Clash When Shifting Forward Gears

.Clutch Out Of Adjustment, .Shift linkage damaged or out of adjustment, .Gears or synchronizers damaged, .Low gear oil level

Transmission Noisy When Moving (RWD Only) Quiet In Neutral With Clutch Engaged

.Worn rear outputshaft bearing

Gear Rattle

.Worn bearings, .Wrong gear oil, .Low gear oil, .Worn gears

Steady Ticking At Idle (Increases With RPM)

.Broken tooth on gear

Gear Clash When Shifting Forward Gears

.Worn or broken synchronizers

Loud Whine In Reverse

.Normal condition (1)

Noise When Stepping On Clutch

.Bad release bearing, .Worn pilot bearing

Ticking Or Screeching As Clutch Is Engaged

.Faulty release bearing, .Uneven pressure plate fingers

Click Or Snap When Clutch Is Engaged

.Worn clutch fork, .Worn or broken front bearing retainer

Transmission Shifts Hard

.Clutch not releasing, .Shift mechanism binding, .Clutch installed backwards

Will Not Shift Into One Gear, Shifts Into All Others

.Bent shift fork, .Worn detent balls

Locked Into Gear, Cannot Shift

.Clutch adjustment, .Worn detent balls

Transmission Jumps Out Of Gear

.Pilot bearing worn,

.Bent shift fork,

.Worn gear teeth or face

.Excessive gear train end play

.Worn synchronizers

.Missing detent ball spring

.Shift mechanism worn or out of

adjustment .Engine or transmission mount

bolts loose or out of adjustment .Transmission not aligned

Shift Lever Rattle

.Worn shift lever or detents

.Worn shift forks

.Worn synchronizers sleeve

Shift Lever Hops Under Acceleration

.Worn engine or transmission mounts

(1) - Most units use spur cut gears in reverse and are noisy

POWERTRAIN

CLUTCH TROUBLE SHOOTING

NOTE: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle configuration. The purpose of this Trouble Shooting information is to provide a list of common causes to problem symptoms. For model-specific Trouble Shooting, refer to SUBJECT, DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

BASIC CLUTCH TROUBLE SHOOTING CHART

CONDITION

POSSIBLE CAUSE

CORRECTION

Incorrect clutch adjustment Adjust clutch

Chattering or Grabbing

Oil, grease or glaze on facings

Loose "U" joint flange

Worn input shaft spline Binding pressure plate Binding release lever Binding clutch disc hub

Unequal pressure plate contact

Loose/bent clutch disc

Incorrect transmission alignment

Worn pressure plate, disc or flywheel

Broken or weak pressure springs

Sticking clutch pedal

Incorrect clutch disc facing

Engine loose in chassis

Disassemble and clean or replace

See DRIVE AXLES article

Replace input shaft Replace pressure plate See CLUTCH article Replace clutch disc

Replace worn/misaligned components

Replace clutch disc Realign transmission

Replace damaged components

Replace pressure plate

Lubricate clutch pedal & linkage

Replace clutch disc

Tighten all mounting bolts

Failure to Release

Oil or grease on clutch facings

Incorrect release lever or pedal adjustment

Worn or broken clutch facings

Bent clutch disc or pressure plate

Clutch disc hub binding on input shaft

Binding pilot bearing

Sticking release bearing sleeve

Clean or replace clutch clutch disc

See CLUTCH article

Replace clutch disc

Replace damaged components

Clean or replace clutch disc and/or input shaft

Replace pilot bearing

Replace release bearing and/or sleeve

Binding clutch cable

See CLUTCH article

Defective clutch master Defective clutch slave Air in hydraulic system

Replace master cylinder Replace slave cylinder Bleed hydraulic system

Rattling

Weak or broken release lever spring

Damaged pressure plate Broken clutch return spring

Worn splines on clutch disc or input shaft

Worn clutch release bearing Dry or worn pilot bearing

Unequal release lever contact

Replace spring and check alignment

Replace pressure plate Replace return spring

Replace clutch disc and/or input shaft

Replace release bearing

Lubricate or replace pilot bearing

Align or replace release lever

Incorrect pedal free play

Warped or damaged clutch disc

Adjust free play

Replace damaged components

Slipping

Pressure springs worn or

Oily, greasy or worn facings

Release pressure plate

Clean or replace clutch disc

Incorrect clutch alignment Realign clutch assembly

Warped clutch disc or pressure plate

Binding release levers or clutch pedal

Replace damaged components

Lubricate and/or replace release components

Squeaking

Worn or damaged release

Dry or worn pilot or release bearing

Pilot bearing turning in crankshaft

Worn input shaft bearing

Incorrect transmission alignment

Dry release fork between pivot

Replace release bearing

Lubricate or replace assembly

Replace pilot bearing and/or crankshaft

Replace bearing and seal

Realign transmission

Lubricate release fork and pivot

Heavy and/or Stiff Pedal

Sticking release bearing sleeve

Replace release bearing and/or sleeve

Dry or binding clutch pedal hub

Floor mat interference with pedal

Dry or binding ball/fork pivots

Faulty clutch cable

Lubricate and align components

Lay mat flat in proper area

Lubricate and align components

Replace clutch cable

Noisy Clutch Pedal

Faulty interlock switch

Self-adjuster ratchet noise

Speed control interlock switch

Replace interlock switch

Lubricate or replace self-adjuster

Lubricate or replace interlock switch

Clutch Pedal Sticks Down

Binding clutch cable

See CLUTCH article

Springs weak in pressure plate

Binding in clutch linkage

Replace pressure plate

Lubricate and free linkage

Noisy

Dry release bearing

Dry or worn pilot bearing

Worn input shaft bearing

Lubricate or replace release bearing

Lubricate or replace bearing

Replace bearing

Transmission Click

Weak springs in pressure plate

Release fork loose on ball stud

Oil on clutch disc damper

Broken spring in slave cylinder

Replace pressure plate

Replace release fork and/or ball stud

Replace clutch disc Replace slave cylinder

DRIVE AXLE - NOISE DIAGNOSIS

Unrelated Noises

Some driveline trouble symptoms are also common to the engine, transmission, wheel bearings, tires, and other parts of the vehicle. Ensure cause of trouble actually is in the drive axle before adjusting, repairing, or replacing any of its parts.

Non-Drive Axle Noises

A few conditions can sound just like drive axle noise and have to be considered in pre-diagnosis. The 4 most common noises are exhaust, tires, CV/universal joints and wheel trim rings.

In certain conditions, the pitch of the exhaust gases may sound like gear whine. At other times, it may be mistaken for a wheel bearing rumble.

Tires, especially radial and snow, can have a high-pitched tread whine or roar, similar to gear noise. Also, some non-standard tires with an unusual tread construction may emit a roar or whine.

Defective CV/universal joints may cause clicking noises or excessive driveline play that can be improperly diagnosed as drive axle problems.

Trim and moldings also can cause a whistling or whining noise. Ensure none of these components are causing the noise before disassembling the drive axle.

Gear Noise

A "howling" or "whining" noise from the ring and pinion gear can be caused by an improper gear pattern, gear damage, or improper bearing preload. It can occur at various speeds and driving conditions, or it can be continuous.

Before disassembling axle to diagnose and correct gear noise, make sure that tires, exhaust, and vehicle trim have been checked as possible causes.

Chuckle

This is a particular rattling noise that sounds like a stick against the spokes of a spinning bicycle wheel. It occurs while decelerating from 40 MPH and usually can be heard until vehicle comes to a complete stop. The frequency varies with the speed of the vehicle.